Emergency safety showers are critical in facilities where individuals are exposed to hazardous chemicals or materials. These safety wash stations provide immediate decontamination to prevent serious injuries or burns from chemical and hazardous exposure. This article explores the various types of safety showers, their key features, and top product recommendations for workplace safety.

What Is a Safety Shower?

A safety shower is an essential wash equipment used to cleanse individuals exposed to hazardous chemicals or materials. These showers are crucial tools in minimizing the risk of injuries, such as burns or exposure. Its overhead design helps ensure the rapid removal of harmful substances from the body through a full-body wash. Safety showers are mandatory in settings where there is a risk of exposure to harmful chemicals and other hazards.

Plumbed vs Portable Safety Showers

Emergency safety showers are classified into two general categories - plumbed and portable safety showers. Plumbed safety showers are fixed installations connected to a reliable source of potable water. They are commonly found in permanent facilities like laboratories, industrial plants, and manufacturing sites. The key advantage of plumbed showers is their ability to provide an uninterrupted and immediate high-volume flow of water, which is essential for effective decontamination.

On the other hand, portable safety showers are designed for flexibility and mobility, ideal for temporary worksites, construction areas, or places where a permanent water supply is not available. These showers rely on a built-in water tank, which needs to be filled with clean water and, in some cases, treated to prevent bacterial growth. Here is a brief summary of the key features and differences between plumbed and portable safety showers:

| Feature | Plumbed Safety Shower | Portable Safety Shower |

| Installation | Permanent; requires a fixed water supply | Mobile; can be set up anywhere with space for the tank |

| Water Supply | Unlimited, as it is connected to a continuous source | Limited to the capacity of the onboard tank; needs regular refilling |

| Flow Rate | Consistent and meets standards (e.g., 20 gallons per minute) | Dependent on tank capacity and pump efficiency; may vary |

| Location | Fixed; requires strategic placement in permanent facilities | Flexible; can be relocated to different sites as needed |

| Maintenance | Regular testing and maintenance required; less frequent water refills | More maintenance-intensive; regular cleaning and refilling needed |

| Usage | Ideal for environments with a high risk of chemical exposure | Suitable for temporary sites or places without direct water access |

| Temperature Control | Easier to manage, as it is typically connected to a controlled water supply | Challenging to maintain water at a safe temperature; risk of thermal shock |

| Cost | Higher initial installation cost; lower ongoing maintenance | Lower initial cost; higher maintenance and operational costs |

How To Use a Safety Shower

Using a safety shower effectively is crucial in the event of chemical exposure to minimize injury. Immediate action is required, with the following steps to be followed:

- Immediate Activation: Quickly reach and activate the shower, using the pull rod or push lever.

- Effective Decontamination: Remove all contaminated clothing immediately to expose the chemical to the flushing water. Stand under the shower for at least 15 minutes, ensuring full-body coverage, and rotate to rinse all areas thoroughly. It's essential to maintain the water temperature to prevent thermal shock or hypothermia, aiming for tepid water that is comfortable yet effective in flushing out contaminants.

- Post-Decontamination Protocol: After rinsing, seek medical attention to address any injuries and report the incident for safety documentation.

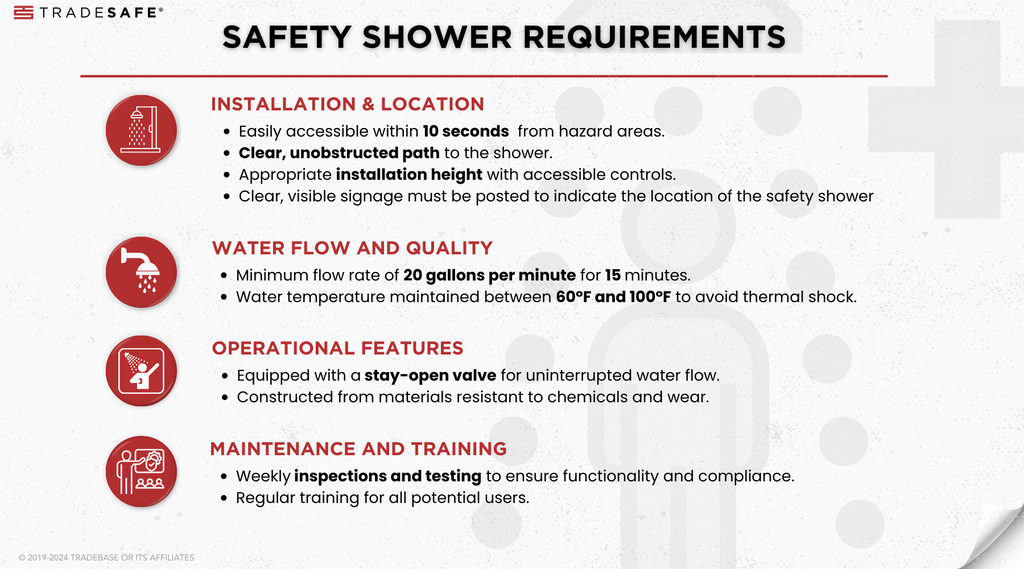

Safety Shower Requirements: Overview

Safety showers must meet specific criteria to ensure they function effectively in emergencies. These requirements are outlined in regulatory standards, such as OSHA and the American National Standards Institute (ANSI) Z358.1, which provides comprehensive guidelines for the installation, performance, and maintenance of emergency eyewash stations and shower equipment.

- Installation and Location: For optimal safety chemical shower functionality, installation and location are key: the unit must be within 10 seconds or 55 feet of hazard areas, have an unobstructed path, and be installed at an accessible height.

- Water Flow and Quality: A minimum flow of 20 gallons per minute for 15 minutes is essential, with temperatures kept between 60°F and 100°F to prevent thermal shock.

- Operational Features: Key elements, such as a stay-open valve, ensure uninterrupted water flow during emergency use, and materials used in the construction of the shower must be resistant to chemicals and wear.

- Maintenance and Training: Regular inspection and maintenance are crucial to ensure the shower's functionality and compliance with safety standards. Clear signage should be posted to facilitate easy location of the shower in emergencies, and regular training should be provided to ensure all potential users are familiar with its operation.

Compliance with ANSI Z358.1 requirements ensures that safety showers are effective and ready for use in emergencies, significantly reducing the risk of injury from chemical exposures. Regular maintenance, testing, and training are essential components of a comprehensive safety program, ensuring that showers function as needed and personnel are familiar with their operation.

Types of Emergency Safety Shower

Safety showers are available in various designs. Each type of emergency safety shower has unique features designed to meet different environmental and situational requirements, ensuring effective and immediate decontamination in case of exposure to hazardous substances. Here is a comprehensive overview of the different types, along with some of the best safety showers for each product type to help you choose the best one for your needs.

Floor-Mounted Safety Shower

Floor-mounted safety showers are stand-alone units that can be installed directly onto the floor of a facility. These showers are versatile and can be placed in strategic locations within a workplace, ensuring that they are accessible in an emergency. The design form of floor-mounted showers allows for easy access, with simple operation mechanisms such as pull levers or push handles that quickly activate the water flow.

Top Pick:

The Hughes Floor Mounted Unheated Safety Shower is designed for indoor use, providing reliable emergency decontamination for workers exposed to hazardous substances. It ensures a controlled flow of water at 20 US gallons per minute, meeting ANSI standards. Key features include an easy-grip pull rod for quick activation, an optional foot treadle for hands-free operation, and a rigorously tested nozzle for even water distribution. This shower is UL certified, adhering to the ANSI Z358.1 Standard for Emergency Eyewash Stations and Shower Equipment.

Ceiling-Mounted Safety Shower

Ceiling-mounted safety showers are installed overhead and are designed to save space while providing effective decontamination. These units are integrated into the ceiling, allowing for a direct downward water flow that covers the entire body. Ceiling-mounted showers are ideal for environments with limited floor space or where a clean and unobtrusive appearance is preferred. Their placement ensures that the shower area remains unobstructed, providing immediate access for rapid decontamination.

Top Pick:

The Acorn S2200-PE27-PR85 is a barrier-free, partially concealed, horizontal ceiling-mounted shower designed for quick and efficient emergency decontamination. It features a vertically dropping stainless steel showerhead and a 1" stay-open ball valve for ease of use. This model meets the ANSI Z358.1-2014 standard, ensuring compliance with safety requirements.

Wall-mounted Safety Shower

This type of safety shower is affixed to a wall and designed to maximize space efficiency while providing immediate decontamination capabilities. These units are particularly useful in environments where floor space is limited. The shower head is typically positioned at a height that ensures full body coverage, and activation is straightforward, often involving a pull handle or lever that releases water quickly and steadily.

Top Pick:

The Global Industrial™ Emergency Shower offers superior safety features with its durable stainless steel construction and quick-activation pull rod, ensuring rapid decontamination. This wall-mountable, horizontally mounted unit meets ANSI Z358.1-2014 standards, providing a reliable 30 PSI flow rate through a 10-inch shower head, ideal for industrial, construction, and healthcare settings. Its corrosion-resistant design and compliance with safety regulations make it an essential fixture for workplace safety.

Emergency Shower Decontamination Booth

Emergency shower decontamination booths offer a complete solution by enclosing the shower area. These chemical shower booths provide privacy and contain the water and any hazardous substances within the unit, preventing contamination of the surrounding environment. Decontamination booths are particularly suitable for high-risk areas where full-body exposure to dangerous chemicals can occur, providing an enclosed space for thorough cleaning and removal of contaminants.

Top Pick:

The HEMCO Emergency Shower/Decontamination Booth is designed to offer a safe and effective solution for immediate decontamination within laboratory settings. Key features include a frosted vinyl strip curtain for easy access and containment of contaminated water splash, stainless steel grab bars for added safety, and a one-piece seamless fiberglass construction with coved corners for easier cleanup. It also includes a raised flow-through floor grate to prevent slippage during use. The unit has a generous size, measuring 40 inches wide, 36 inches deep, and 90 inches high, ensuring ample space for effective decontamination.

Combination Eyewash Showers

Combination eyewash showers merge the functionality of an eyewash station with a safety shower, offering a dual-purpose solution for decontamination. This type of emergency shower station is essential in areas where both eye and body exposure to hazardous substances is possible. The eyewash station allows for targeted cleaning of the eyes and face, while the shower provides full-body decontamination. Combination units are space-efficient and cost-effective, making them a popular choice in various industrial and laboratory settings.

Top Pick:

The Speakman SE-695 Combination Plumbed Eyewash and Shower Unit features a dual spray outlet eye/face wash with flip-top dust covers and an ABS plastic bowl. Mounted on a powder-coated galvanized steel stanchion, it includes an 8" corrosion-resistant shower head and a high-visibility pull rod for easy operation. Meeting ANSI Z358.1 standards, it delivers a controlled flow rate ensuring effective decontamination, ideal for industrial environments requiring reliable emergency washing facilities.

Freeze-Resistant Safety Shower

Freeze-resistant safety showers are designed for use in environments where the temperature can drop below freezing, preventing the water inside the shower from freezing. These showers are equipped with insulation that line pipes and self-regulating heating cables to maintain water at a usable temperature. This design ensures that the shower remains operational even in cold conditions, providing reliable access to decontamination facilities in all weather.

Top Pick:

The Bradley Frost-Proof Wall-Mounted Drench Shower and Eyewash station is engineered for reliability in cold climates, ensuring functionality even in freezing temperatures. Key features include a frost-proof valve system to prevent freezing within the unit, a wall-mounted design for space efficiency, and a combination of drench shower and eyewash capabilities. This product is designed for both indoor and outdoor installations, offering versatile placement options and compliance with ANSI safety standards, making it a robust choice for harsh environments.

Drench Emergency Shower

Drench emergency showers are designed for situations where a large volume of water is required quickly to dilute and remove hazardous chemicals. These showers provide a high flow rate, ensuring that the entire body can be drenched rapidly to minimize the damage caused by chemical exposure. Drench showers are often used in industrial settings where the risk of large-scale chemical spills is present. They are designed for ease of use, allowing affected individuals to receive immediate and thorough decontamination.

Top Pick:

The Haws 8163 AXION® MSR Emergency Drench Shower is a ceiling-mounted unit designed for efficient emergency decontamination. It features the AXION MSR hydrodynamic showerhead, providing a uniform and controlled flow to enhance the decontamination process. The showerhead's design reduces the physical pressure of the water, creating a comfortable yet effective rinsing experience. This model, which is wheelchair accessible and meets ANSI/ISEA Z358.1 standards, is ideal for various settings where quick and thorough decontamination is necessary.

Drench Hoses

Drench hoses are flexible hoses with a nozzle that can be used for targeted rinsing of specific body parts or equipment. They offer a versatile and direct method of decontamination, allowing for the precise application of water to affected areas. Drench hoses can be used independently or supplement to other safety showers to enhance the decontamination process. They are particularly useful in areas where space is constrained or for rinsing off contaminants from areas that are difficult to reach with a fixed shower head.

Top Pick:

The Guardian G5022 Emergency Eyewash/Drench Hose Unit is a versatile, deck-mounted safety device offering dual functionality. It can operate as a fixed eyewash station or a drench hose, providing flexibility for various emergency scenarios. With two GS-Plus spray heads, a forged brass squeeze valve for easy activation, and an 8-foot reinforced PVC hose, it meets ANSI Z358.1-2014 standards. Ideal for environments requiring both targeted and broader decontamination options, this unit enhances workplace safety and emergency responsiveness.

Tank-mounted Portable Safety Shower

Tank-mounted portable showers feature a large water tank that is mounted on a frame or cart, allowing for mobility across the site. These mobile safety showers can be filled in advance and transported to various locations as needed. The tank provides a reservoir of water that is used to supply the shower, offering a reliable source of decontamination fluid in areas lacking infrastructure for permanent safety showers.

Top Pick:

The Haws 8740 Emergency Overhead Tank Shower, designed for indoor use, adheres to ANSI/ISEA Z358.1 standards, ensuring reliability in 60° - 100° F ambient temperatures. Its modular frame, with forklift slots and mounting feet, supports a 330-gallon tank and features an auto-fill valve, breather vent, and a 2" NPT ball valve for shower piping. High-visibility signage enhances quick identification, with options for an eyewash assembly and a cleansing stick for bacterial protection, making it versatile and compliant for safety needs.

Gravity-fed Portable Safety Shower

Gravity-fed portable emergency safety showers rely on the force of gravity to supply water. They have a water tank elevated above the showerhead for stock water, ensuring a consistent flow rate during use. These portable safety shower models are simple in design and operation, making them ideal for sites where mechanical or pressurized systems are impractical. The height of the water tank dictates the pressure of the water flow, which must be sufficient to meet safety standards for effective decontamination.

Top Pick:

The Bradley Gravity-Fed Safety Shower is designed for environments where a direct water connection is not available. It features a 550-gallon portable tank that allows for placement in various locations. The unit ensures a steady flow of water, complying with ANSI standards for emergency safety showers. This gravity-fed system is ideal for remote or temporary work areas, providing reliable and immediate decontamination capabilities.

Trailer-mounted Portable Safety Shower

Trailer-mounted portable showers are comprehensive units that include a water tank, shower, and often an eyewash station, all mounted on a trailer for easy transportation. These showers are designed for rapid deployment to incident sites and can be towed by standard vehicles. They are particularly useful for large construction sites, mining operations, or agricultural areas where the location of potential chemical exposure risks can change frequently.

Top Pick:

The ATS ShieldSafe 400-Gallon Mobile Safety Shower & Eyewash Trailer is a robust and mobile solution for on-site emergency decontamination. Rated for Class 1 Division 2 environments, it features a 400-gallon heated water tank, ensuring ANSI-compliant tepid water availability. The trailer is built with a powder-coated steel frame, includes a stainless steel nozzle delivering 20 GPM for safety showers, and has an eyewash station with a 0.4 GPM flow rate. This emergency shower station is quipped for road travel, it has lights, brakes, safety signage, and is powered by a pneumatic pump, making it ideal for remote or temporary worksites.

FAQs

Should you remove clothes in a safety shower?

Yes, contaminated clothing should be removed quickly in a safety shower to ensure thorough decontamination and prevent prolonged chemical exposure.

For how long should you drench a chemical splash victim under a safety shower?

A chemical splash victim should be drenched under a safety shower for at least 15 minutes to effectively rinse off hazardous substances.

When is a safety shower required?

A safety shower is required in workplaces where employees are exposed to harmful chemicals or substances that could cause injury or burns upon contact, such as laboratories, industrial plants, and manufacturing facilities.

Should a chemical safety shower have a floor drain?

Yes, a chemical shower should ideally have a floor drain to manage the flow of contaminated water away from the user and prevent flooding in the area.

How often should emergency showers be flushed?

Emergency showers should be flushed weekly to ensure they are in good working order and to clear any sediment or contaminants from the water lines.