-

0%

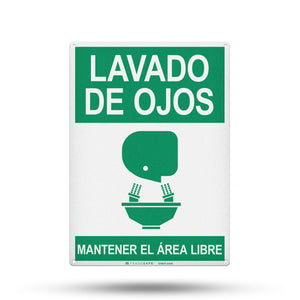

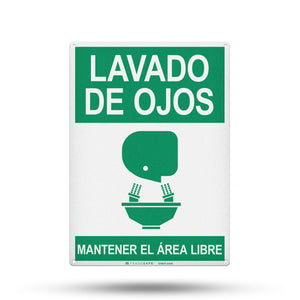

Lavado De Ojos Mantener El Área Libre (Eye Wash Keep Area Clear) Letrero de Aluminio

Precio habitual $24.95Precio habitual$25.000%Precio de oferta $24.95 -

Agotado

Señal de aluminio transparente para lavado de ojos Keep Area

Precio habitual $24.95Precio habitual$25.000%Precio de oferta $24.95 -

0%

Cartel Aluminio Estación De Primeros Auxilios

Precio habitual $24.95Precio habitual$25.000%Precio de oferta $24.95 -

-20%

Letrero de aluminio para protección auditiva y gafas de seguridad

Precio habitual $19.95Precio habitual$25.00-20%Precio de oferta $19.95 -

-20%

Zapatos de Seguridad Requeridos Señal de Aluminio

Precio habitual $19.95Precio habitual$25.00-20%Precio de oferta $19.95 -

-20%

Zapatos de seguridad requeridos Letrero de aluminio

Precio habitual $19.95Precio habitual$25.00-20%Precio de oferta $19.95 -

-20%

Letrero de aluminio Lentes de Seguridad Requeridos

Precio habitual $19.95Precio habitual$25.00-20%Precio de oferta $19.95 -

-20%

Gafas de seguridad requeridas Letrero de aluminio

Precio habitual $19.95Precio habitual$25.00-20%Precio de oferta $19.95 -

-20%

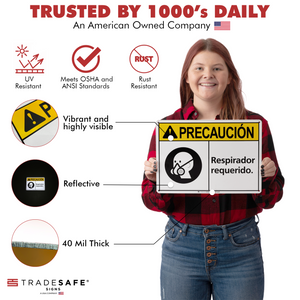

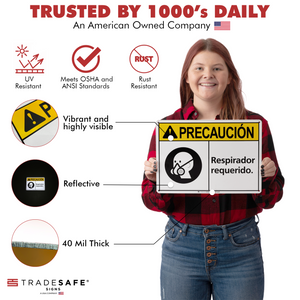

Señal de aluminio Respirador Requerido

Precio habitual $19.95Precio habitual$25.00-20%Precio de oferta $19.95 -

-20%

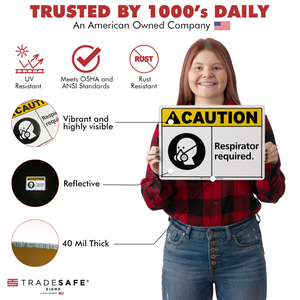

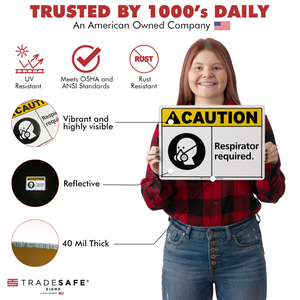

Letrero de aluminio requerido para respirador

Precio habitual $19.95Precio habitual$25.00-20%Precio de oferta $19.95 -

-20%

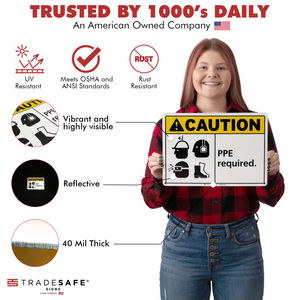

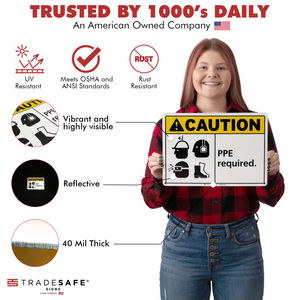

PPE Requerido (PPE Required) Letrero de aluminio

Precio habitual $19.95Precio habitual$25.00-20%Precio de oferta $19.95 -

-20%

Letrero de aluminio requerido de PPE

Precio habitual $19.95Precio habitual$25.00-20%Precio de oferta $19.95 -

-34%

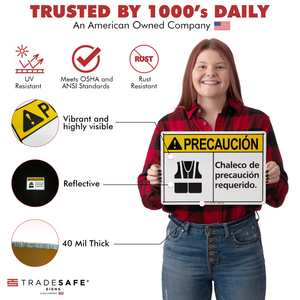

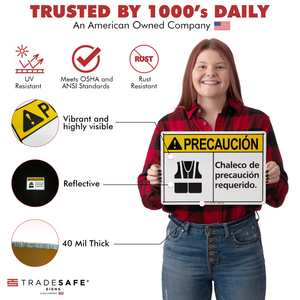

Chaleco de Precaución Requerido Señal de Aluminio

Precio habitual $19.95Precio habitual$30.00-34%Precio de oferta $19.95 -

-34%

Letrero de aluminio requerido para chaleco de seguridad

Precio habitual $19.95Precio habitual$30.00-34%Precio de oferta $19.95 -

-20%

Protección Auditiva Requerida (Protección auditiva requerida) Letrero de aluminio

Precio habitual $19.95Precio habitual$25.00-20%Precio de oferta $19.95 -

-20%

Señal de aluminio de protección auditiva requerida

Precio habitual $19.95Precio habitual$25.00-20%Precio de oferta $19.95 -

-20%

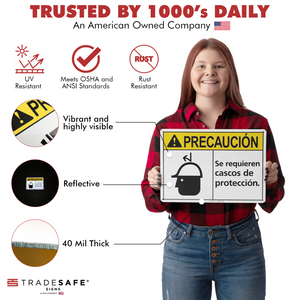

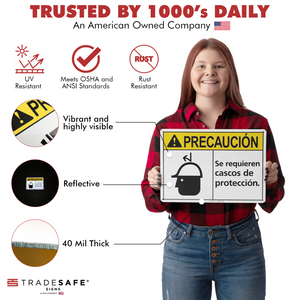

Se Requieren Cascos de Protección (Hard Hats Required) Letrero de Aluminio

Precio habitual $19.95Precio habitual$25.00-20%Precio de oferta $19.95 -

-20%

Letrero de aluminio requerido para cascos

Precio habitual $19.95Precio habitual$25.00-20%Precio de oferta $19.95 -

-20%

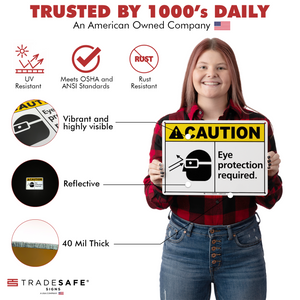

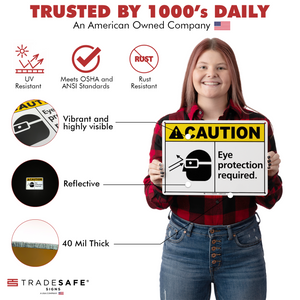

Protección Ocular Requerida (Eye Protection Required) Letrero de Aluminio

Precio habitual $19.95Precio habitual$25.00-20%Precio de oferta $19.95 -

-20%

Señal de aluminio de protección ocular requerida

Precio habitual $19.95Precio habitual$25.00-20%Precio de oferta $19.95 -

Agotado

Señal antideslizante para piso – One Way/Circulación – One Way Sign – Circulación de Una Vía – Bilingüe (inglés/español)

Precio habitual $36.95Precio habitual$60.00-38%Precio de oferta $36.95 -

-38%

Señal de suelo antideslizante – Señal Stop Wait Here

Precio habitual $36.95Precio habitual$60.00-38%Precio de oferta $36.95 -

-38%

Letrero antideslizante para piso – Mantener el Área Libre – Keep Area Clear Sign en español

Precio habitual $36.95Precio habitual$60.00-38%Precio de oferta $36.95 -

-38%

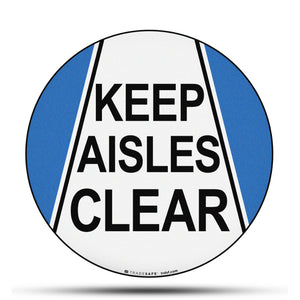

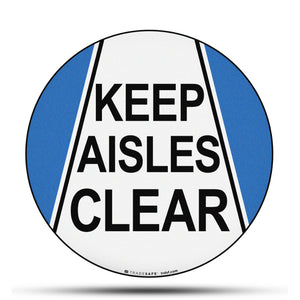

Letrero antideslizante para piso – Letrero para mantener los pasillos despejados

Precio habitual $36.95Precio habitual$60.00-38%Precio de oferta $36.95 -

-38%

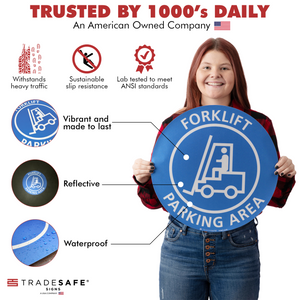

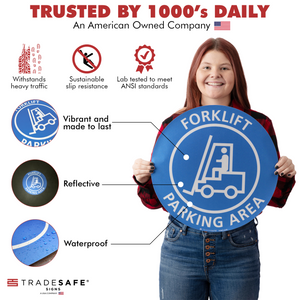

Señal de piso antideslizante - Señal de área de estacionamiento de montacargas

Precio habitual $36.95Precio habitual$60.00-38%Precio de oferta $36.95 -

-38%

Señal de suelo antideslizante: señal de prohibido el paso de carretillas elevadoras en esta zona

Precio habitual $36.95Precio habitual$60.00-38%Precio de oferta $36.95 -

-38%

Letrero antideslizante para piso – Stop – Letrero solo para empleados

Precio habitual $36.95Precio habitual$60.00-38%Precio de oferta $36.95 -

Agotado

Letrero Antideslizante para Piso – Extinguidor – Letrero de Flecha de Extintor de Incendios en Español

Precio habitual $36.95Precio habitual$60.00-38%Precio de oferta $36.95 -

-38%

Letrero de piso antideslizante - Letrero de flecha de extintor de incendios

Precio habitual $36.95Precio habitual$60.00-38%Precio de oferta $36.95 -

-38%

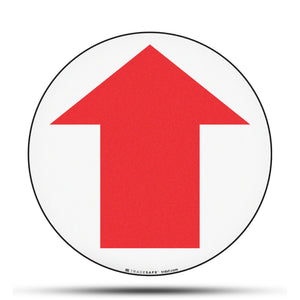

Calcomanía de piso con letrero de flecha roja

Precio habitual $36.95Precio habitual$60.00-38%Precio de oferta $36.95 -

-38%

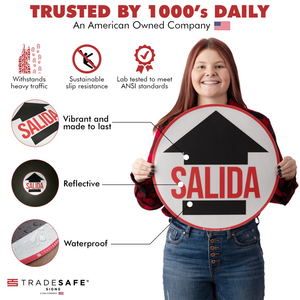

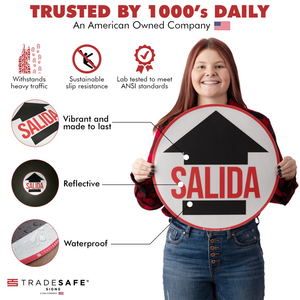

Señal de salida con piso de flecha hacia arriba Pegatina

Precio habitual $36.95Precio habitual$60.00-38%Precio de oferta $36.95 -

-38%

Señal de salida con piso de flecha hacia arriba Pegatina

Precio habitual $36.95Precio habitual$60.00-38%Precio de oferta $36.95 -

Agotado

Vinilo para suelo señal español alto

Precio habitual $36.95Precio habitual$60.00-38%Precio de oferta $36.95 -

-38%

Señal de piso de la estación de lavado de ojos

Precio habitual $36.95Precio habitual$60.00-38%Precio de oferta $36.95 -

-38%

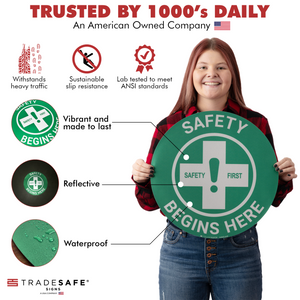

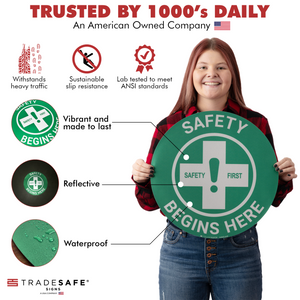

Señal de piso La seguridad comienza aquí

Precio habitual $36.95Precio habitual$60.00-38%Precio de oferta $36.95 -

-38%

Letrero antideslizante para piso - Letrero resbaladizo cuando está mojado

Precio habitual $36.95Precio habitual$60.00-38%Precio de oferta $36.95 -

-38%

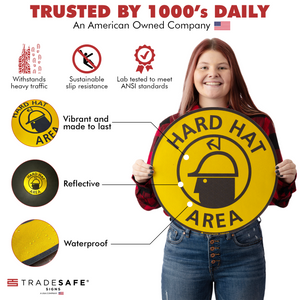

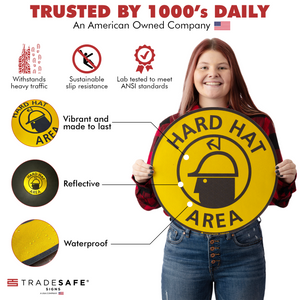

Área de Uso De Cascos Signo de piso español

Precio habitual $36.95Precio habitual$60.00-38%Precio de oferta $36.95 -

-38%

Letrero de piso para el área del casco

Precio habitual $36.95Precio habitual$60.00-38%Precio de oferta $36.95 -

-38%

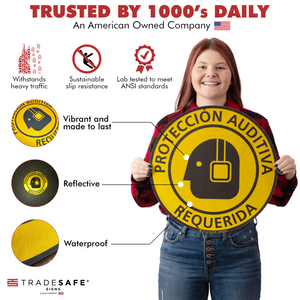

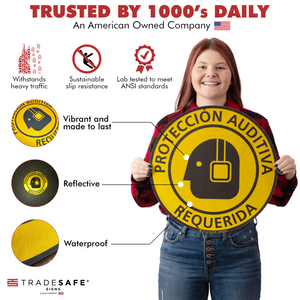

Protección Auditiva Requerida Señal de piso en español

Precio habitual $36.95Precio habitual$60.00-38%Precio de oferta $36.95 -

-38%

Señal de piso de protección auditiva requerida

Precio habitual $36.95Precio habitual$60.00-38%Precio de oferta $36.95 -

-38%

Letrero de piso para basurero

Precio habitual $36.95Precio habitual$60.00-38%Precio de oferta $36.95 -

-38%

Lentes De Seguridad Requeridos Signo De Piso Español

Precio habitual $36.95Precio habitual$60.00-38%Precio de oferta $36.95 -

Agotado

Zapatos De Seguridad Requeridos Signo De Piso Español

Precio habitual $36.95Precio habitual$60.00-38%Precio de oferta $36.95 -

-38%

Señal de piso de zapatos de seguridad requeridos

Precio habitual $36.95Precio habitual$60.00-38%Precio de oferta $36.95 -

-38%

Mire su señal de piso de paso

Precio habitual $36.95Precio habitual$60.00-38%Precio de oferta $36.95 -

-38%

Señal de piso de tráfico peatonal solamente

Precio habitual $36.95Precio habitual$60.00-38%Precio de oferta $36.95 -

-39%

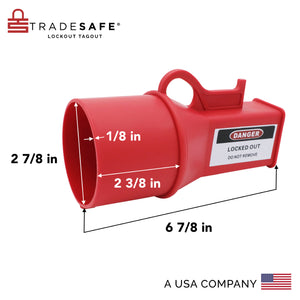

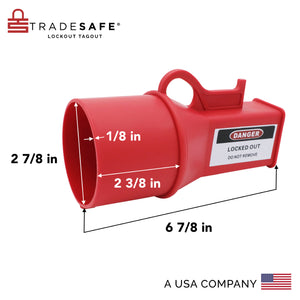

Dispositivo de bloqueo de salida eléctrica: diámetro del cuerpo de 2⅞”

Precio habitual $29.95Precio habitual$49.00-39%Precio de oferta $29.95 -

-49%

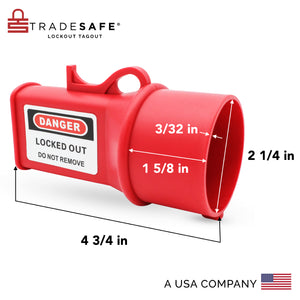

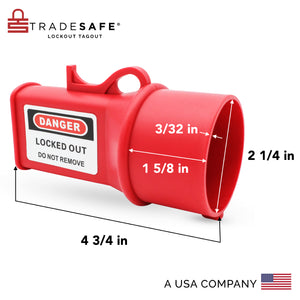

Dispositivo de bloqueo de salida eléctrica: diámetro del cuerpo de 2¼”

Precio habitual $24.95Precio habitual$49.00-49%Precio de oferta $24.95

Es imperativo que los lugares de trabajo industriales den prioridad a la salud y la seguridad en el trabajo. Debido a que las fábricas, plantas industriales y otros lugares de trabajo de alto riesgo tienen muchos peligros laborales, las empresas deben asegurarse de que sus empleados tengan las herramientas y la capacitación para mantener un entorno de trabajo seguro.

La Administración de Salud y Seguridad Ocupacional (OSHA, por sus siglas en inglés) es parte del Departamento de Trabajo de los Estados Unidos que garantiza la seguridad y la salud de los empleados al establecer y hacer cumplir las normas, además de brindar capacitación, divulgación, información y apoyo.

En TRADESAFE , cada producto está hecho de materiales de primera calidad, diseñado con precisión para que sea fácil de usar y construido para cumplir con los estándares de OSHA. Nuestra colección incluye absorbentes, estaciones de lavado de ojos, dispositivos y suministros de bloqueo y etiquetado, y letreros. Mantén tu comercio seguro con TRADESAFE, una marca de seguridad industrial de confianza.