-

-30%

Juego de candados de bloqueo y etiquetado con llaves iguales - 10 candados naranjas - 2 llaves por candado

Precio habitual $20.95Precio habitual$30.00-30%Precio de oferta $20.95 -

-38%

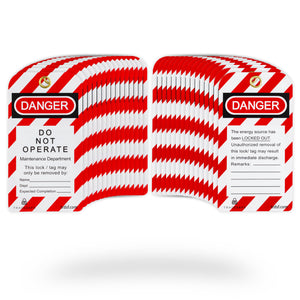

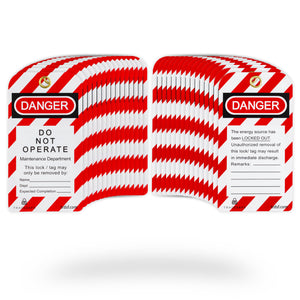

Etiquetas de "Peligro" de bloqueo y etiquetado: paquete de 30

Precio habitual $36.95Precio habitual$60.00-38%Precio de oferta $36.95 -

-45%

Juego de candados de bloqueo y etiquetado con llaves iguales - 10 candados naranjas - 2 llaves por candado

Precio habitual $65.95Precio habitual$120.00-45%Precio de oferta $65.95 -

-38%

Etiquetas de “Peligro” de Bloqueo y Etiquetado en Español – Paquete de 30

Precio habitual $36.95Precio habitual$60.00-38%Precio de oferta $36.95 -

-38%

Etiquetas bilingües de bloqueo y etiquetado “Peligro” – Paquete de 30

Precio habitual $36.95Precio habitual$60.00-38%Precio de oferta $36.95 -

-40%

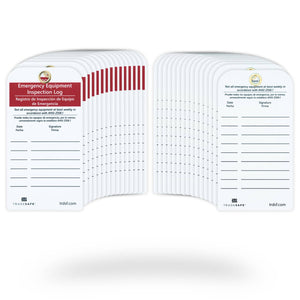

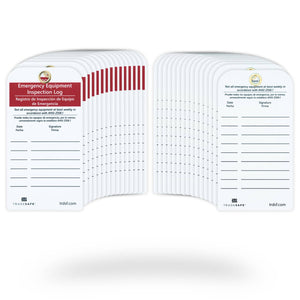

Etiquetas bilingües para inspección de estaciones de lavado de ojos - Paquete de 30

Precio habitual $35.95Precio habitual$60.00-40%Precio de oferta $35.95 -

-50%

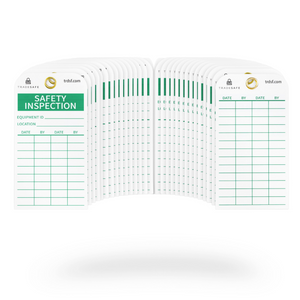

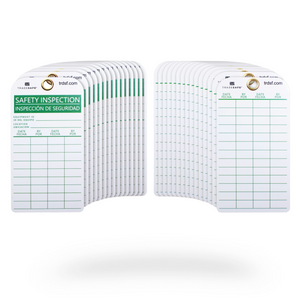

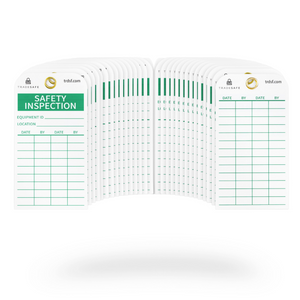

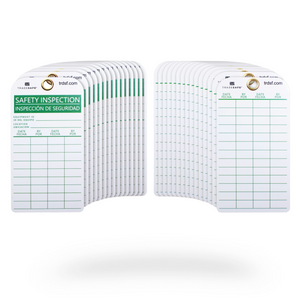

Etiquetas de inspección de seguridad - Paquete de 30

Precio habitual $29.95Precio habitual$60.00-50%Precio de oferta $29.95 -

-50%

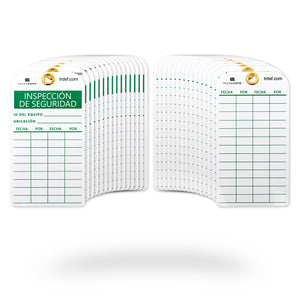

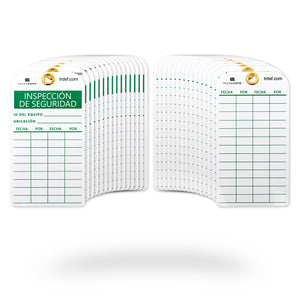

Etiquetas de Inspección de Seguridad Españolas – Paquete de 30

Precio habitual $29.95Precio habitual$60.00-50%Precio de oferta $29.95 -

-50%

Etiquetas bilingües de inspección de seguridad - Paquete de 30

Precio habitual $29.95Precio habitual$60.00-50%Precio de oferta $29.95 -

-40%

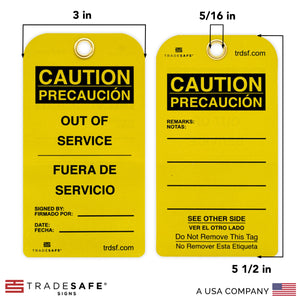

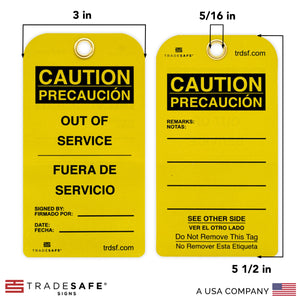

Etiquetas de precaución fuera de servicio - Paquete de 30

Precio habitual $35.95Precio habitual$60.00-40%Precio de oferta $35.95 -

-40%

Etiquetas de precaución fuera de servicio en español - Paquete de 30

Precio habitual $35.95Precio habitual$60.00-40%Precio de oferta $35.95 -

-40%

Etiquetas bilingües de precaución fuera de servicio - Paquete de 30

Precio habitual $35.95Precio habitual$60.00-40%Precio de oferta $35.95 -

-36%

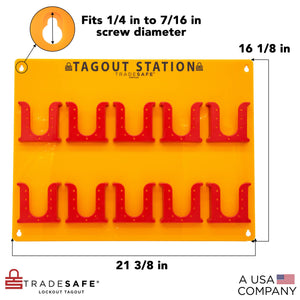

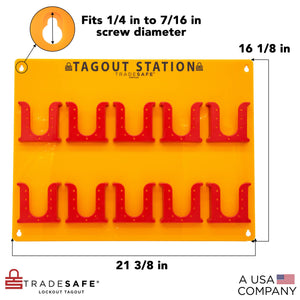

Estación de bloqueo y etiquetado para etiquetas LOTO: 150 etiquetas incluidas

Precio habitual $189.95Precio habitual$299.00-36%Precio de oferta $189.95 -

-65%

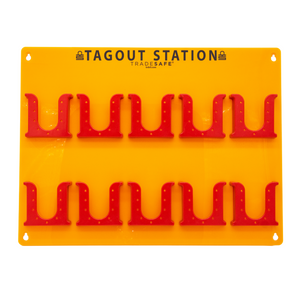

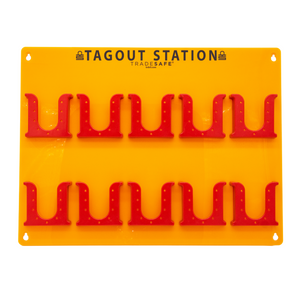

Estación de bloqueo y etiquetado para etiquetas LOTO - Etiquetas no incluidas

Precio habitual $69.95Precio habitual$199.00-65%Precio de oferta $69.95 -

-62%

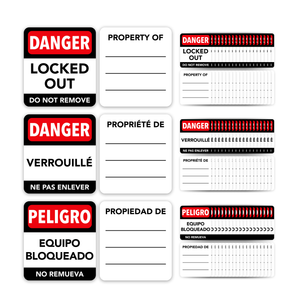

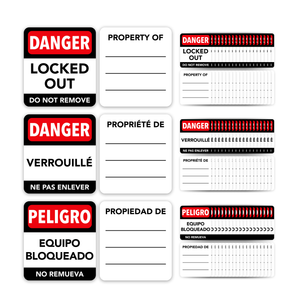

Lockout Tagout Padlock Labels - English, Spanish, French - Pack of 60

Precio habitual $18.95Precio habitual$50.00-62%Precio de oferta $18.95 -

-60%

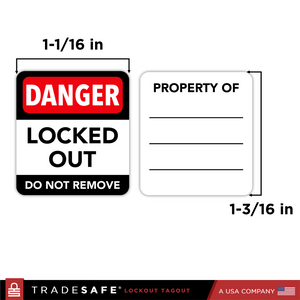

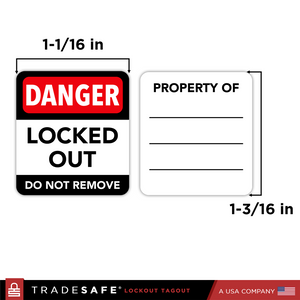

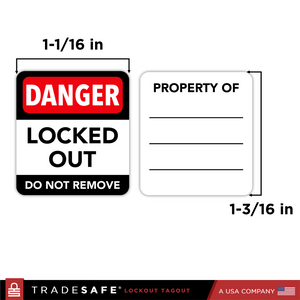

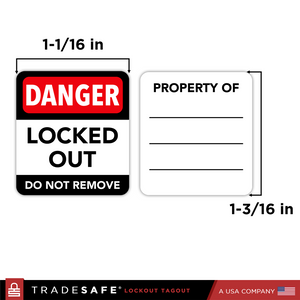

Lockout Tagout Padlock Labels - Pack of 20

Precio habitual $13.95Precio habitual$35.00-60%Precio de oferta $13.95 -

-80%

Etiquetas de Inspección de Seguridad Españolas – Paquete de 30

Precio habitual $11.99Precio habitual$60.00-80%Precio de oferta $11.99 -

-78%

Etiquetas de Inspección de Seguridad Españolas – Paquete de 30

Precio habitual $12.99Precio habitual$60.00-78%Precio de oferta $12.99 -

-78%

Etiquetas de Inspección de Seguridad Españolas – Paquete de 30

Precio habitual $12.99Precio habitual$60.00-78%Precio de oferta $12.99

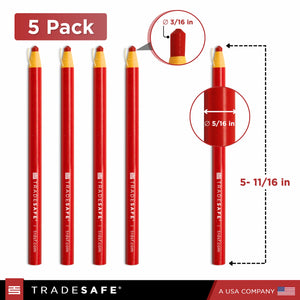

Con la ayuda de las etiquetas de bloqueo y etiquetado, los trabajadores pueden alertar fácil y eficientemente a otros sobre posibles peligros. Debido a que estas etiquetas LOTO son muy visibles y fácilmente perceptibles, podrán transmitir advertencias e información importantes.

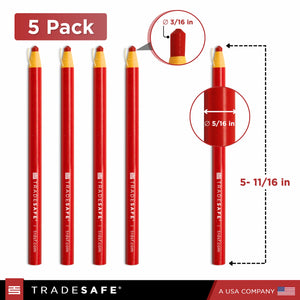

Todas las etiquetas de bloqueo de TRADESAFE están hechas de plástico de nailon o vinilo duradero y resistente al desgarro. También se pueden escribir y están diseñados para ser fáciles de leer. Cualquier cosa escrita en estas etiquetas de bloqueo seguirá siendo legible incluso cuando estén expuestas al agua o a condiciones ambientales adversas.

Las etiquetas de bloqueo y etiquetado ayudan a los empleados a estar atentos a los peligros, realizar un seguimiento de las tareas y descubrir quién de ellos es responsable de qué acciones. Etiquetas como estas son importantes para garantizar que los programas de bloqueo y etiquetado y sus procedimientos no solo cumplan con OSHA 1919.147 , sino que también se sigan al pie de la letra.