-

-23%

Gabinete de estación de bloqueo y etiquetado con 70 dispositivos LOTO

Precio habitual $369.95Precio habitual$479.95-23%Precio de oferta $369.95 -

Agotado

Almacenamiento portátil de candados de seguridad: se adapta a 12 candados de bloqueo

Precio habitual $22.95Precio habitual$39.00-41%Precio de oferta $22.95 -

-75%

Bolsa con cincha para bloqueo y etiquetado, 17-1/4” x 10”

Precio habitual $24.95Precio habitual$100.00-75%Precio de oferta $24.95 -

-70%

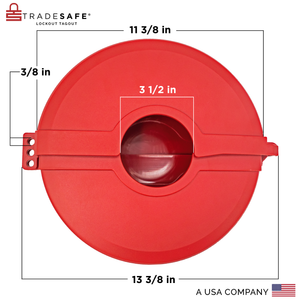

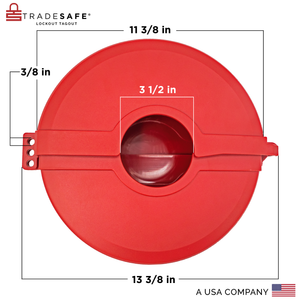

Bloqueo de botón pulsador – Redondo – Mediano

Precio habitual $35.80Precio habitual$120.00-70%Precio de oferta $35.80 -

-65%

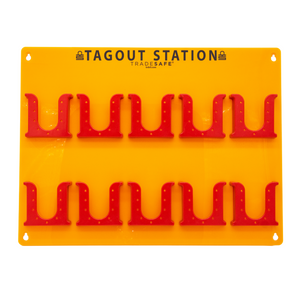

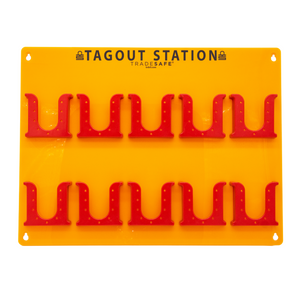

Estación de bloqueo y etiquetado para etiquetas LOTO - Etiquetas no incluidas

Precio habitual $69.95Precio habitual$199.00-65%Precio de oferta $69.95 -

Agotado

Bloqueo de válvula de compuerta: diámetro de manija de válvula de 6-½” a 10”

Precio habitual $54.95Precio habitual$109.00-50%Precio de oferta $54.95 -

Agotado

Bloqueo de válvula de compuerta: diámetro de manija de válvula de 10" a 13"

Precio habitual $64.95Precio habitual$119.00-45%Precio de oferta $64.95 -

-27%

Kit profesional de bloqueo y etiquetado: 2 llaves por candado

Precio habitual $239.95Precio habitual$329.95-27%Precio de oferta $239.95 -

-62%

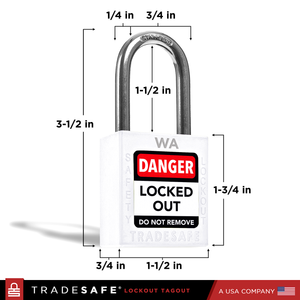

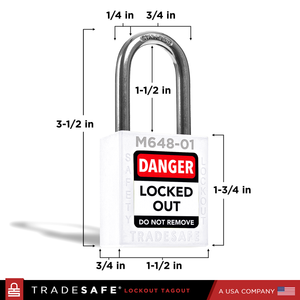

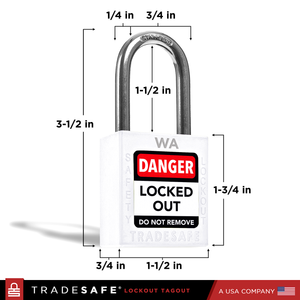

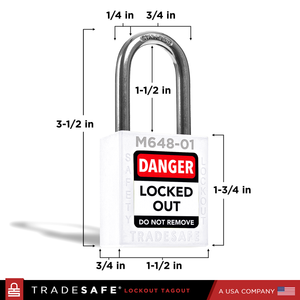

Keyed Alike Lockout Locks - 10 White Padlocks - 2 Keys Per Lock

Precio habitual $59.95Precio habitual$159.00-62%Precio de oferta $59.95 -

-23%

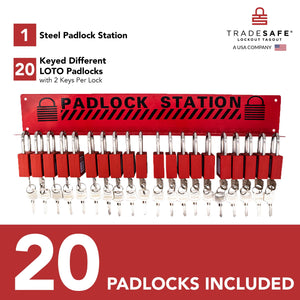

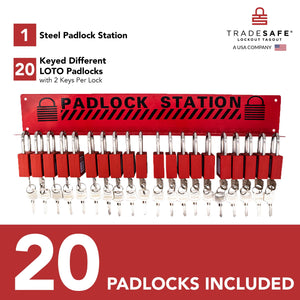

Estación de bloqueo y etiquetado de candados de seguridad - Se adapta a 20 candados - Candados LOTO incluidos

Precio habitual $153.95Precio habitual$199.00-23%Precio de oferta $153.95 -

-49%

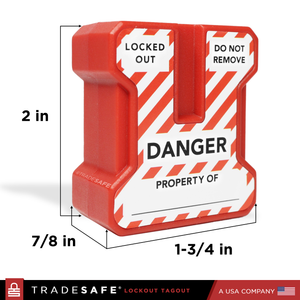

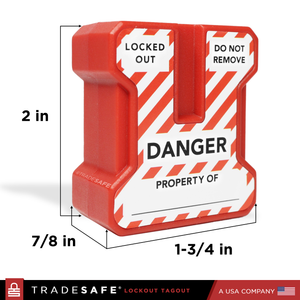

Bloqueo de botón pulsador - Redondo - Juego de 3 piezas

Precio habitual $29.95Precio habitual$59.00-49%Precio de oferta $29.95 -

-42%

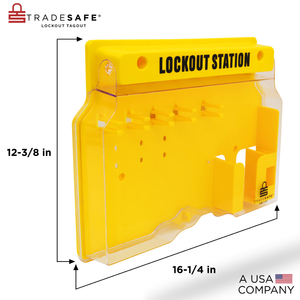

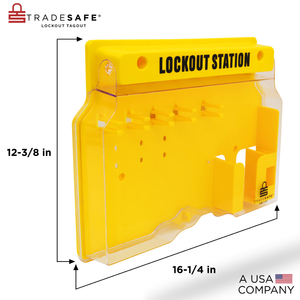

Estación de bloqueo y etiquetado: grande

Precio habitual $77.95Precio habitual$135.00-42%Precio de oferta $77.95 -

-62%

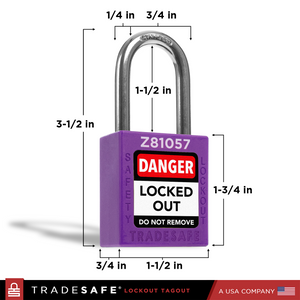

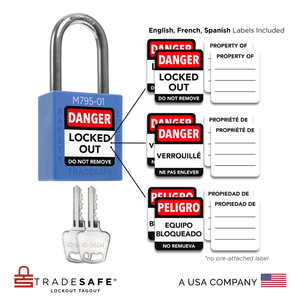

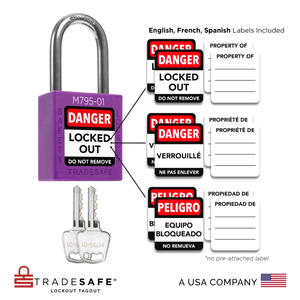

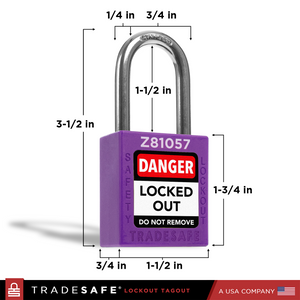

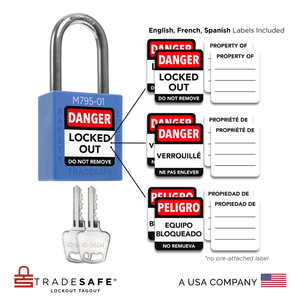

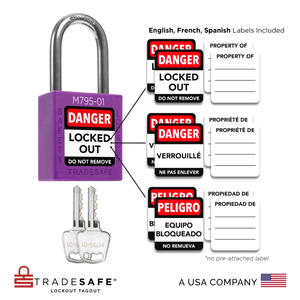

Juego de candados de bloqueo y etiquetado con llaves iguales - 10 candados morados - 2 llaves por candado

Precio habitual $59.95Precio habitual$159.00-62%Precio de oferta $59.95 -

-49%

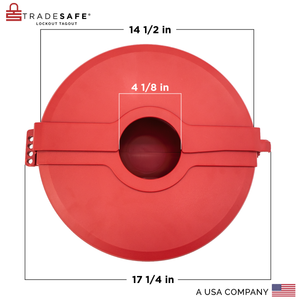

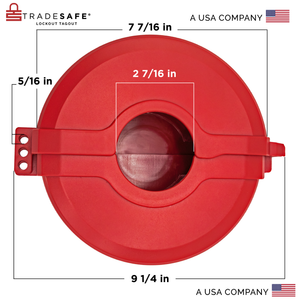

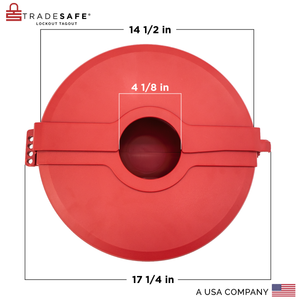

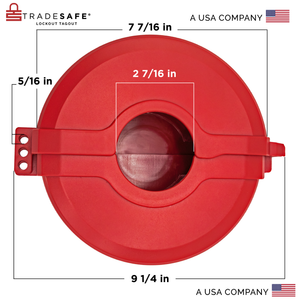

Bloqueo de válvula de compuerta: diámetro de manija de válvula de 5" a 6-½"

Precio habitual $29.95Precio habitual$59.00-49%Precio de oferta $29.95 -

-40%

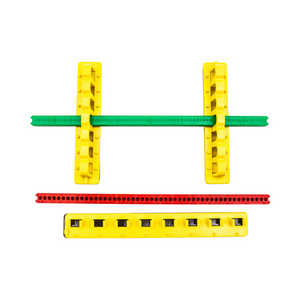

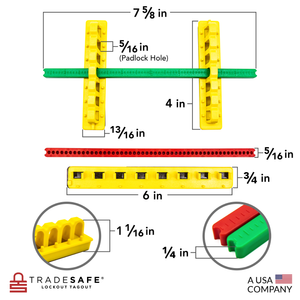

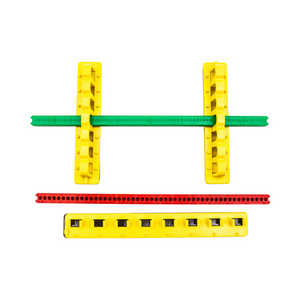

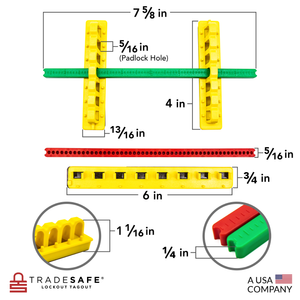

Bloqueo de disyuntores - Kit de bloqueo de disyuntores - 480/600 voltios

Precio habitual $29.95Precio habitual$50.00-40%Precio de oferta $29.95 -

-51%

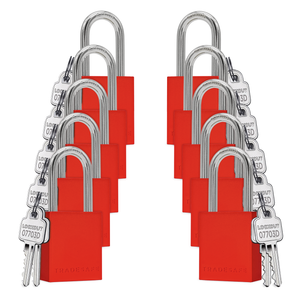

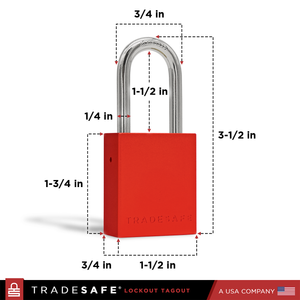

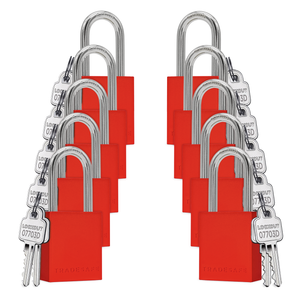

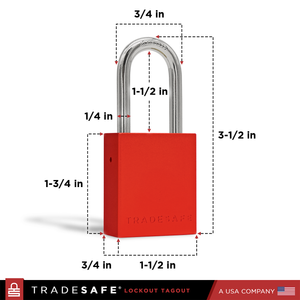

Juego de candados de bloqueo y etiquetado con diferentes llaves - 10 candados de seguridad rojos - 2 llaves por candado

Precio habitual $77.95Precio habitual$159.00-51%Precio de oferta $77.95 -

-26%

Kit profesional de bloqueo y etiquetado: 2 llaves por candado

Precio habitual $319.95Precio habitual$429.95-26%Precio de oferta $319.95 -

-62%

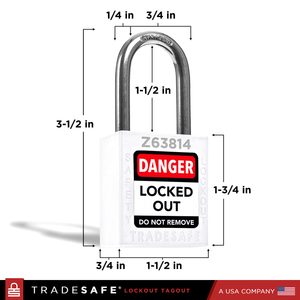

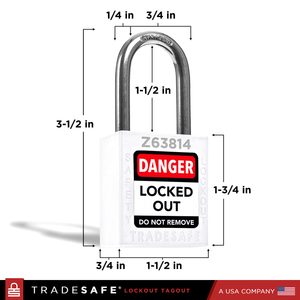

Keyed Different Lockout Locks - 10 White Padlocks - 2 Keys Per Lock

Precio habitual $59.95Precio habitual$159.00-62%Precio de oferta $59.95 -

-54%

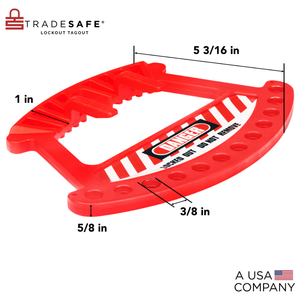

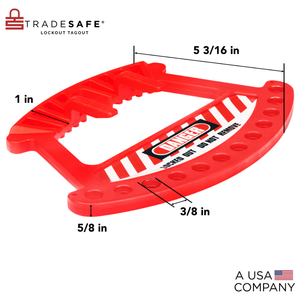

Power Cord Plug Lockout Device - 1 Pack

Precio habitual $22.95Precio habitual$50.00-54%Precio de oferta $22.95 -

-51%

Juego de candados de bloqueo y etiquetado con diferentes llaves - 10 candados de seguridad rojos - 2 llaves por candado

Precio habitual $77.95Precio habitual$159.00-51%Precio de oferta $77.95 -

-51%

Juego de candados de bloqueo y etiquetado con diferentes llaves - 10 candados de seguridad rojos - 2 llaves por candado

Precio habitual $77.95Precio habitual$159.00-51%Precio de oferta $77.95 -

-52%

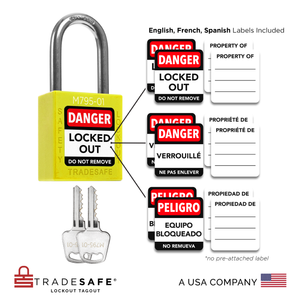

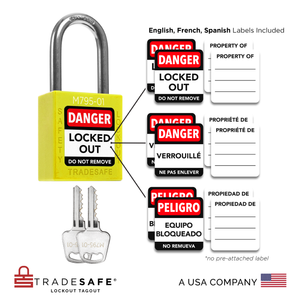

Juego de candados de bloqueo y etiquetado con llaves iguales - 10 candados amarillos - 2 llaves por candado

Precio habitual $94.95Precio habitual$199.00-52%Precio de oferta $94.95 -

-14%

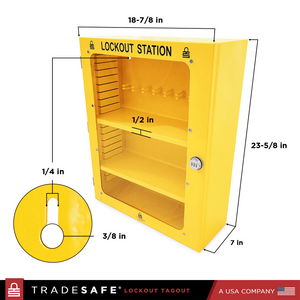

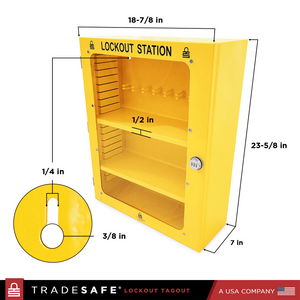

Gabinete de la estación de bloqueo y etiquetado: no se incluyen dispositivos de bloqueo y etiquetado

Precio habitual $299.95Precio habitual$349.95-14%Precio de oferta $299.95 -

-33%

Gabinete de estación de bloqueo y etiquetado con 70 dispositivos LOTO

Precio habitual $159.95Precio habitual$239.95-33%Precio de oferta $159.95 -

-23%

Gabinete de estación de bloqueo y etiquetado con 70 dispositivos LOTO

Precio habitual $369.95Precio habitual$479.95-23%Precio de oferta $369.95 -

-14%

Bolsa de bloqueo y etiquetado - Bolsa de bloqueo roja

Precio habitual $59.95Precio habitual$70.00-14%Precio de oferta $59.95 -

-47%

Confined Space Cover

Precio habitual $39.95Precio habitual$75.00-47%Precio de oferta $39.95 -

-64%

Keyed Alike Unlimited Lockout Locks - 10 White Padlocks - 2 Keys Per Lock

Precio habitual $59.95Precio habitual$165.00-64%Precio de oferta $59.95 -

-62%

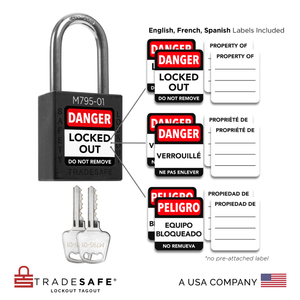

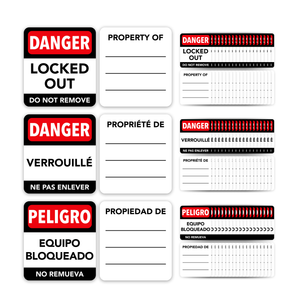

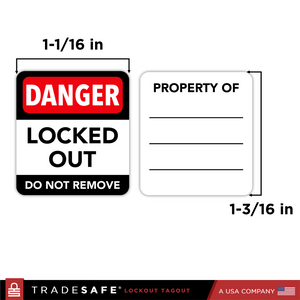

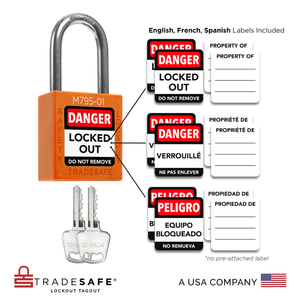

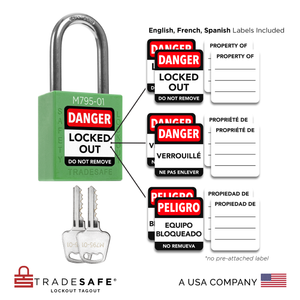

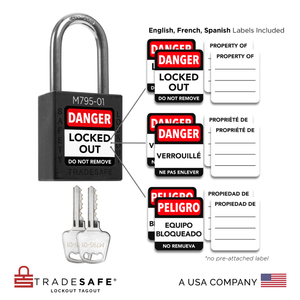

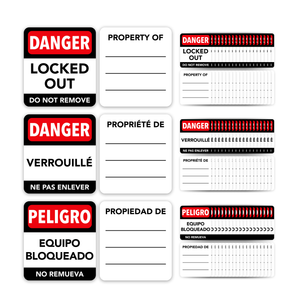

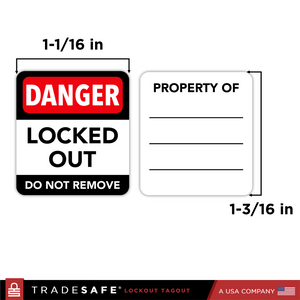

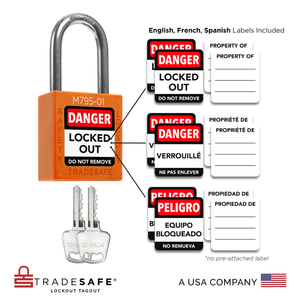

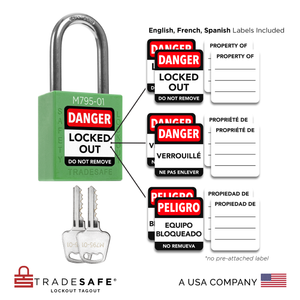

Lockout Tagout Padlock Labels - English, Spanish, French - Pack of 60

Precio habitual $18.95Precio habitual$50.00-62%Precio de oferta $18.95 -

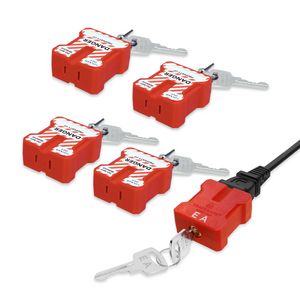

Agotado

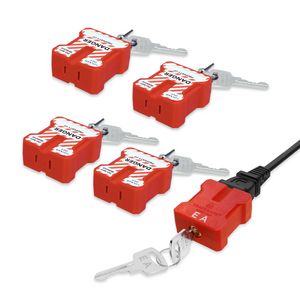

Power Cord Plug Lockout Device - 5 Pack

Precio habitual $79.95Precio habitual$150.00-47%Precio de oferta $79.95 -

-49%

Nylon Drum Security Plug With 2 Rubber Gaskets

Precio habitual $15.95Precio habitual$31.50-49%Precio de oferta $15.95 -

-51%

Juego de candados de bloqueo y etiquetado con diferentes llaves - 10 candados de seguridad rojos - 2 llaves por candado

Precio habitual $77.95Precio habitual$159.00-51%Precio de oferta $77.95 -

-52%

Juego de candados de bloqueo y etiquetado con llaves iguales - 10 candados amarillos - 2 llaves por candado

Precio habitual $94.95Precio habitual$199.00-52%Precio de oferta $94.95 -

-52%

Juego de candados de bloqueo y etiquetado con llaves iguales - 10 candados amarillos - 2 llaves por candado

Precio habitual $94.95Precio habitual$199.00-52%Precio de oferta $94.95 -

-52%

Juego de candados de bloqueo y etiquetado con llaves iguales - 10 candados amarillos - 2 llaves por candado

Precio habitual $94.95Precio habitual$199.00-52%Precio de oferta $94.95 -

-52%

Juego de candados de bloqueo y etiquetado con llaves iguales - 10 candados amarillos - 2 llaves por candado

Precio habitual $94.95Precio habitual$199.00-52%Precio de oferta $94.95 -

-25%

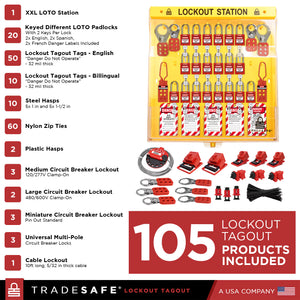

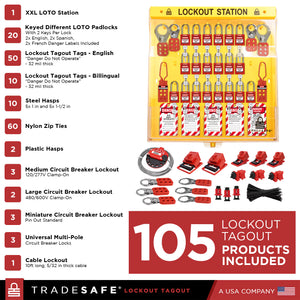

Estación de bloqueo y etiquetado - XL

Precio habitual $399.95Precio habitual$529.95-25%Precio de oferta $399.95 -

-17%

Bolsa de bloqueo y etiquetado - Bolsa de bloqueo roja

Precio habitual $49.95Precio habitual$60.00-17%Precio de oferta $49.95 -

-51%

Keyed Different Lockout Locks with Master Keys - 10 White Padlocks - 2 Keys Per Lock

Precio habitual $77.95Precio habitual$159.00-51%Precio de oferta $77.95 -

-43%

Power Plug Lock Keyed Alike Unlimited - 5 Pack - 2 Keys Each

Precio habitual $84.95Precio habitual$150.00-43%Precio de oferta $84.95 -

-49%

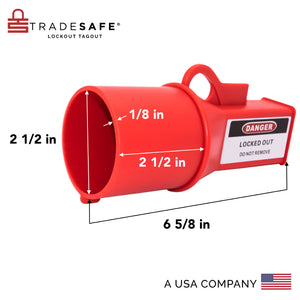

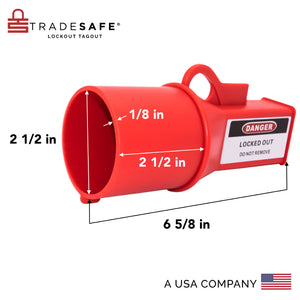

Dispositivo de bloqueo de salida eléctrica: diámetro del cuerpo de 2½”

Precio habitual $24.95Precio habitual$49.00-49%Precio de oferta $24.95 -

-36%

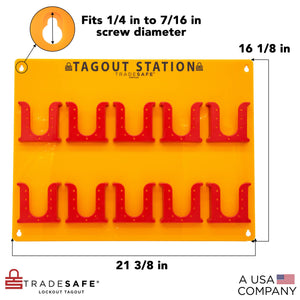

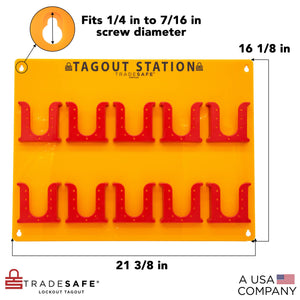

Estación de bloqueo y etiquetado para etiquetas LOTO: 150 etiquetas incluidas

Precio habitual $189.95Precio habitual$299.00-36%Precio de oferta $189.95 -

-51%

Juego de candados de bloqueo y etiquetado con diferentes llaves - 10 candados de seguridad rojos - 2 llaves por candado

Precio habitual $77.95Precio habitual$159.00-51%Precio de oferta $77.95 -

Agotado

Juego de candados de bloqueo y etiquetado con diferentes llaves - 10 candados de seguridad rojos - 2 llaves por candado

Precio habitual $77.95Precio habitual$159.00-51%Precio de oferta $77.95 -

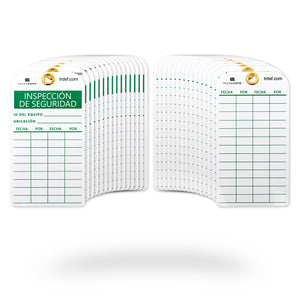

-50%

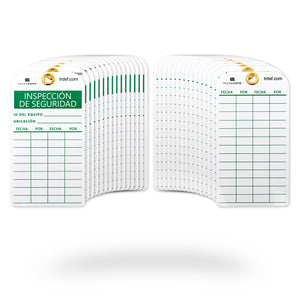

Etiquetas de Inspección de Seguridad Españolas – Paquete de 30

Precio habitual $29.95Precio habitual$60.00-50%Precio de oferta $29.95 -

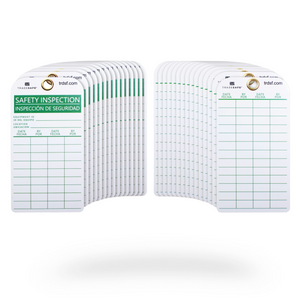

-50%

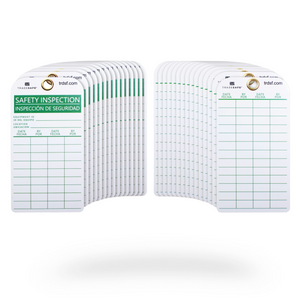

Etiquetas bilingües de inspección de seguridad - Paquete de 30

Precio habitual $29.95Precio habitual$60.00-50%Precio de oferta $29.95 -

-42%

OSHA GHS Hazcom Poster

Precio habitual $28.95Precio habitual$50.00-42%Precio de oferta $28.95 -

-42%

Pictogramas GHS Póster

Precio habitual $28.95Precio habitual$50.00-42%Precio de oferta $28.95

El programa de bloqueo y etiquetado es un componente importante de sus prácticas de seguridad para mantener su lugar de trabajo seguro y compatible con OSHA. Sirve para proteger a los trabajadores de la energía peligrosa no controlada que puede escapar de la maquinaria o el equipo durante el aislamiento, el servicio o el mantenimiento. Como resultado, es fundamental que los trabajadores tengan acceso a los suministros correctos de bloqueo y etiquetado, así como la capacitación LOTO adecuada, en sus áreas de trabajo.

En TRADESAFE , la seguridad nunca se compromete sino que se maximiza. Nuestra colección incluye una amplia gama de información de seguridad de bloqueo y etiquetado y soluciones disponibles para adaptarse a enchufes y enchufes, válvulas, paneles, disyuntores y más. Cada dispositivo de bloqueo y etiquetado es fácil de usar y está fabricado con materiales de alta calidad que pueden resistir los entornos hostiles y peligrosos comunes en las instalaciones industriales.

TRADESAFE solo ofrece suministros LOTO de primera calidad diseñados con precisión para ayudarlo a cumplir con los estándares OSHA 1910.147 (Control de energía peligrosa) en su lugar de trabajo y al mismo tiempo inculcar responsabilidad y rendición de cuentas entre sus trabajadores. Obtenga un socio de seguridad confiable con TRADESAFE .