Working with chemicals can pose serious health risks if not handled safely. This is where a lab chemical hygiene plan (CHP) comes in, a comprehensive set of procedures and practices designed to protect workers from the dangers associated with the use of hazardous chemicals. It acts as a blueprint for the safe handling, storage, and disposal of chemicals, minimizing the risk of accidents, injuries, and environmental contamination.

This article provides a comprehensive guide to understanding CHP, covering everything from its crucial components to practical strategies for successfully incorporating and maintaining a CHP.

What is a Chemical Hygiene Plan (CHP)?

A Chemical Hygiene Plan (CHP) is a set of written procedures and protective laboratory practices designed for workers' defense from the health hazards associated with hazardous chemicals in the workplace. It is mandated by OSHA's Laboratory Standard (29 CFR 1910.1450) for laboratories using hazardous chemicals but is also highly recommended for any facility where hazardous chemicals are handled.

The primary purpose of a CHP is to:

- Minimize the risk of worker exposure to hazardous chemicals

- Prevent chemical-related accidents and injuries

- Protect the environment from hazardous waste contamination

- Ensure compliance with relevant regulations and safety standards

Who Needs a Chemical Hygiene Plan?

A CHP is required for laboratories using hazardous chemicals, but it is also essential for any facility that uses, handles, and stores hazardous chemicals to ensure safety and compliance with regulations. This includes:

- Research laboratories

- Academic laboratories

- Industrial settings

- Manufacturing facilities

- Healthcare facilities

- Agricultural settings

Additionally, employees and managers in environments where chemical exposure is possible should be familiar with their facility's CHP to understand the safety protocols and emergency procedures.

Benefits of a Chemical Hygiene Plan

Implementing CHP offers several benefits that enhance occupational safety and health, compliance, and efficiency in environments where chemicals are used. Here’s a closer look at these benefits:

- Reduces Chemical Exposure Risks: A CHP provides clear guidelines and procedures for the use of hazardous chemicals, significantly reducing the risk of exposure to harmful substances. This includes proper storage, handling, and disposal methods that prevent accidents.

- Prevents Accidents and Injuries: With specific lab safety protocols in place, such as spill response procedures and emergency exits, a CHP helps minimize the occurrence of chemical-related accidents and injuries.

- Ensures Consistency in Safety Standards: By following a CHP, facilities ensure that they meet consistent safety standards, which are crucial for both internal audits and external inspections.

- Systematic Response to Emergencies: Part of a CHP involves regular safety training along with detailed emergency procedures for all employees, which prepares them to handle emergencies effectively and safely.

- Minimizes Environmental Impact: CHPs require protocols for the proper disposal of hazardous waste, which helps minimize the environmental impact of chemical use.

- Promotes a Culture of Safety: A strong Chemical Hygiene Plan promotes a culture of safety that permeates all levels of the organization, making safety a shared responsibility among all employees.

Key Elements of a Chemical Hygiene Plan (CHP)

A Chemical Hygiene Plan encompasses several critical elements, each designed to ensure safety and compliance within environments where hazardous chemicals are handled. Here's a brief overview of what is discussed or required for each key component:

Standard Operating Procedures (SOPs)

This component involves creating detailed, written procedures for safely handling hazardous chemicals in laboratories. SOPs cover everything from the proper way to use, store, and dispose of chemicals to specific lab safety protocols for avoiding contamination and exposure. The development of SOPs requires a clear understanding of chemical properties, potential hazards, and the necessary precautions for safe handling. These procedures must be accessible to all employees and regularly updated.

Engineering Controls

Engineering controls focus on integrating physical modifications into the workplace to reduce or eliminate occupational exposure to hazardous chemicals. This could include the installation of ventilation systems, fume hoods, eyewash stations, or other devices that help control the environment. The design and implementation of these controls must align with the specific hazards present in the facility. Regular maintenance and testing are required to ensure their effectiveness.

Personal Protective Equipment (PPE)

PPE consists of clothing and devices worn to protect the body from potential exposure to hazardous chemicals. This section discusses the various types of personal protective equipment, such as gloves, goggles, face shields, and respiratory protection, and the circumstances under which each is necessary. Selecting the appropriate PPE for a given hazard, proper fitting, regular maintenance, and training on correct usage are essential. Employees must understand the limitations and proper care of their personal protective equipment to ensure it provides maximum protection.

Training and Information

Effective training programs are crucial for educating staff about the risks associated with the chemicals they handle and the safety measures in place. Training typically covers chemical hazard recognition, the use of PPE, emergency procedures, and the proper use of engineering controls. Training must be comprehensive, ongoing, and adapted to include new safety information or changes in procedures. Documentation of training sessions and employee attendance is also necessary for compliance and safety audits.

Exposure Monitoring and Medical

This component discusses the need for health and medical surveillance programs for employees who are regularly exposed to the use of hazardous chemicals. Exposure monitoring and medical aims to identify early signs of health effects resulting from exposure to hazardous chemicals. Implementation of medical monitoring programs depends on the level of risk and the specific chemicals handled. Regular check-ups and specific tests may be required, depending on the potential health hazards identified.

High Hazard Work Pre-Approval

Tasks that involve especially hazardous substances, such as carcinogens or highly toxic chemicals, necessitate prior approval to ensure comprehensive risk assessments and mitigation strategies are implemented beforehand. This process is crucial for confirming that all potential hazards have been considered and adequate safety measures are in place. The approval process must be documented, outlining who is responsible for giving the green light and what specific criteria must be met, ensuring that all high-risk activities are monitored and controlled effectively to prevent accidents.

Responsibility for the Chemical Hygiene Plan

The implementation and maintenance of the CHP are overseen by a Chemical Hygiene Officer (CHO) who ensures the plan is current and comprehensive. The CHO plays a pivotal role in fostering a safety culture by continually assessing laboratory practices and chemical management systems. The CHO must possess a strong background in chemical safety and regulatory knowledge. They need the authority to enforce safety protocols and make necessary adjustments to the CHP, ensuring the plan adapts to new regulations, scientific knowledge, and technological advancements.

Further Employee Protection when Working with Hazardous Substances

Work involving particularly hazardous substances demands stricter safety measures to protect employees from significant health risks. These provisions are intended to address the unique dangers posed by substances that are carcinogenic, highly toxic, or have high reactivity. Enhanced lab safety protocols might include the use of advanced containment systems, such as glove boxes or closed systems, stricter access controls, and comprehensive training specific to handling these dangerous chemicals. Regular health monitoring and detailed record-keeping are also essential to track potential exposures and ensure ongoing protection.

Human Health Effects from Exposure to Hazardous Chemicals

Employee exposure to hazardous chemicals in the workplace can have a range of adverse health effects on the human body. These effects can vary widely depending on the type of chemical, the level and duration of exposure, and individual susceptibility. Here's a detailed look at the potential human health effects of chemical exposure:

Acute Effects

- Immediate Symptoms: Exposure to some chemicals can cause immediate symptoms such as irritation to the eyes, skin, and respiratory system. For example, acids can cause severe burns, while solvents may cause dizziness, headaches, or respiratory distress.

- Short-term Toxicity: Some chemicals might not cause immediate symptoms but can result in poisoning or other severe health issues shortly after exposure. This includes organ damage or severe allergic reactions.

Chronic Effects

- Long-term Illnesses: Chronic exposure to certain chemicals can lead to long-term health issues such as cancer, liver and kidney damage, reproductive disorders, and neurological problems. For instance, prolonged exposure to benzene can cause leukemia.

- Sensitization: Repeated exposure to certain substances can lead to sensitization, where an individual develops an allergic reaction to a substance after repeated exposure. This can result in conditions like asthma or dermatitis.

Environmental Factors

- Multiple Chemical Sensitivity: In some cases, exposure to various chemicals in small quantities can cause a condition known as multiple chemical sensitivity (MCS), characterized by a complex array of symptoms that recur chronically in response to multiple, chemically unrelated substances.

- Synergistic Effects: Sometimes, the health impact of a chemical is exacerbated by the presence of other chemicals. For example, smoking can increase the toxicity of asbestos exposure, significantly raising the risk of lung cancer.

Delayed Effects

- Latent Diseases: Certain chemicals can have effects that appear long after the initial exposure, often years later. Mesothelioma, a type of cancer associated with asbestos exposure, is an example of such a delayed effect.

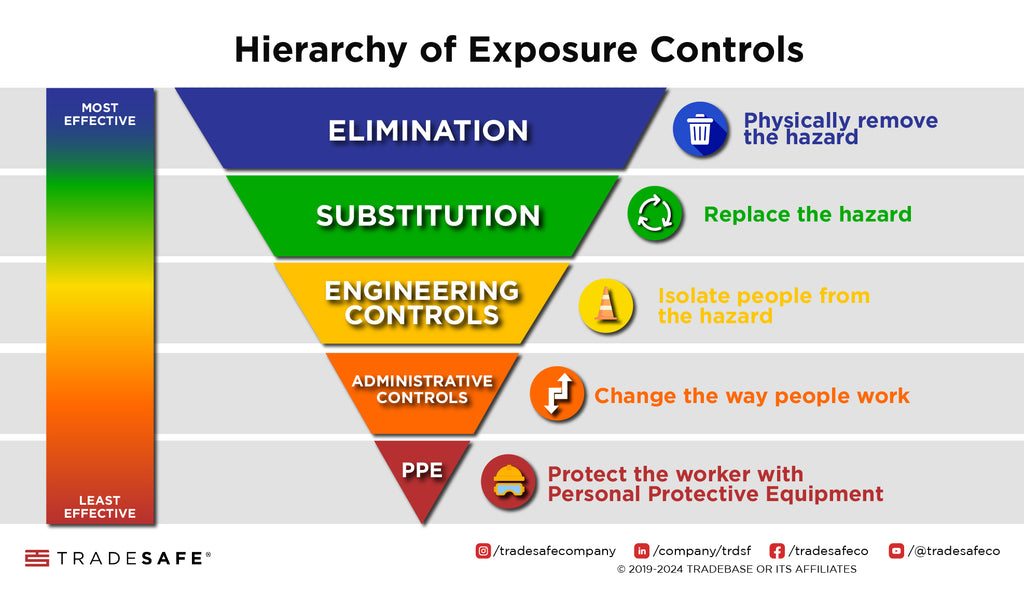

Hierarchy of Exposure Control Practices

Exposure Control Practices is a set of strategies employed within a Chemical Hygiene Plan to minimize the risk of workers coming into contact with hazardous chemicals. These practices involve a hierarchy of approaches, with the most effective methods prioritized.

Implementing and Maintaining a Chemical Hygiene Plan

1. Responsibilities of the CHO

- Duties and Qualifications: The CHO is tasked with the crucial role of ensuring the CHP is effectively implemented and maintained. This position requires a robust understanding of chemical safety, risk management, and relevant regulations.

- Oversight of the CHP Program: The CHO oversees all aspects of the CHP, from ensuring compliance with regulations to adapting the plan in response to new safety data or operational changes within the facility.

2. Communication and Documentation

- Regular Communication of CHP Updates to Employees: All changes and updates to the CHP must be communicated to employees regularly. This ensures that everyone is informed about their roles and responsibilities in maintaining a safe working environment.

- Maintaining Records of Training, Inspections, and Incidents: Keeping detailed records is crucial for compliance and safety monitoring. This includes documentation of all training sessions, safety inspections, and any incidents related to chemical handling.

3. Periodic Review and Updates

- Regular Review and Revision of the CHP: The CHP should be reviewed and updated regularly to ensure it remains effective and relevant. This includes assessing whether the current safety practices are adequate and if the procedures align with the latest industry standards and regulations.

- Incorporating New Safety Practices and Regulations: As new safety technologies emerge and regulations change, the CHP must be updated to incorporate these elements. This ensures ongoing compliance and enhancement of the safety environment within the workplace.

Chemical Hygiene Plan Vs Hazard Communication

Both Chemical Hygiene Plan and Hazard Communication Program aim to protect workers from chemical hazards. The CHP is specific to laboratory environments and focuses on comprehensive safety practices for handling hazardous chemicals, including the use of personal protective equipment, engineering controls, and specific procedures. HazCom, guided by OSHA's Hazard Communication Standard 1910.1200, applies to all industries and is centered around ensuring that information about chemical hazards and associated protective measures is communicated to both employers and employees.

| Feature | Chemical Hygiene Plan (CHP) | Hazard Communication (HazCom) |

|

Scope |

Specific to laboratory environments addressing unique risks. | Broad application, relevant to any workplace handling hazardous chemicals. |

|

Purpose |

Ensures safe handling of chemicals in labs through detailed procedures and safety measures. | Ensures that chemical hazard information is communicated to employers and employees. |

| Level of Detail | Highly detailed, including protocols for emergency responses and specific laboratory tasks. | Focuses on the communication of hazards through labels and safety data sheets, not on how to handle chemicals. |

| Integration | Integrated into daily laboratory management and operations. | Foundational safety requirement ensuring basic knowledge of hazards and precautions. |

| Legal Requirements | Required by regulatory bodies specific to laboratory safety standards. | Governed by OSHA's Hazard Communication Standard 1910.1200, applicable universally across industries. |

| Documentation | Includes SOPs, chemical inventories, training records, and emergency procedures. | Requires maintenance of safety data sheets and proper labeling of chemical containers. |

Chemical Hygiene Plan FAQs

Who is responsible for updating the general chemical hygiene plan?

The responsibility for updating the general Chemical Hygiene Plan typically falls to the Chemical Hygiene Officer (CHO). The CHO is tasked with ensuring that the plan remains current and compliant with all relevant safety and health regulations.

Who is responsible for updating the lab-specific chemical hygiene plan?

The lab-specific Chemical Hygiene Plan is usually updated by the lab manager or principal investigator, under the guidance of the Chemical Hygiene Officer. The lab manager ensures that the specific practices and hazards of the particular lab are accurately reflected in the plan.

Who is required to understand and follow the chemical hygiene plan?

All personnel who work with hazardous chemical or are potentially exposed to hazardous chemicals in the workplace are required to understand and follow the Chemical Hygiene Plan. This includes lab technicians, researchers, custodial staff, and any other employees who might come into contact with chemicals during their work.

What are the 4 basic hazards chemicals can present?

Chemicals can present four basic types of hazards:

- Physical hazards - These include risks like flammability, explosiveness, and reactivity.

- Health hazards - These cover effects like toxicity, carcinogenicity, and chemical burns or irritation.

- Environmental hazards - These refer to the potential of a chemical to harm the environment, such as water or soil contamination.

- Asphyxiation hazards - These are risks associated with gases that can displace oxygen in the air and pose suffocation risks.

What type of hazards do the standard pictograms represent?

The standard pictograms under the Globally Harmonized System (GHS) represent various hazards:

- Flame: Represents flammables, self-reactives, and self-heating chemicals.

- Exclamation mark: Indicates health hazards like skin and eye irritant effects.

- Health hazard: Identifies serious health risks such as carcinogenicity and respiratory sensitization.

- Corrosion: Depicts substances that cause skin corrosion or metal corrosion.

- Exploding bomb: Used for explosives, self-reactives, and organic peroxides.

- Gas cylinder: Indicates gases under pressure.

- Flame over circle: Represents oxidizers.

- Environment (optional): Shows environmental hazards such as aquatic toxicity.

- Skull and crossbones: Warns of acute toxicity that can cause death or toxicity with short exposure.