Confined spaces are common in many industrial settings, from construction sites to chemical plants. These environments pose significant risks due to their restrictive nature and potential exposure to hazardous conditions. Understanding these risks and implementing strict safety protocols is crucial to protect workers who must enter these spaces.

Key Takeaways

- Confined space entry permit is essential to authorize safe entry, ensuring all safety protocols are in place before workers access a particular confined space.

- Conducting initial and periodic tests of the confined space environment is crucial for detecting hazards and maintaining safety during operations.

- Completing a confined space course and entry training equips workers with the necessary skills and knowledge to safely navigate confined spaces.

- The OSHA confined space standard requires employers to implement safety measures, including the preparation of rescue and emergency services, for all confined space operations.

- Avoiding continuous employee occupancy in confined spaces reduces risks, ensuring workers are exposed to hazards only for the necessary duration.

What Is A Confined Space?

A confined space, as defined by the Occupational Safety and Health Administration (OSHA), is any enclosed or partially enclosed space that is not designed for continuous human occupancy, has limited or restricted means for entry or exit, and can pose serious hazards to workers entering the space. These spaces are often uncomfortable and potentially dangerous due to their design and the type of work performed within them. Some examples of areas considered confined spaces include:

- Utility vaults

- Pits

- Manholes

- Tunnels

- Equipment housings

- Pipelines

- Silos

- Sewers

Key Characteristics of Confined Spaces

Confined spaces are unique in their structure and potential hazards. The primary characteristics that define these spaces include:

- Limited Entries and Exits: The entrances and exits of confined spaces are typically narrow, which can complicate both routine and emergency egress and ingress. For example, manholes, ducts, and crawl spaces have limited openings, making it challenging for equipment and rescuers to reach someone quickly during an emergency.

- Not Designed for Continuous Occupancy: These spaces are generally designed for storage, processing, or accessing equipment for maintenance rather than for workers to stay for extended periods. Examples include underground vaults, tanks, and silos, where tasks are usually brief but require entry for specific operational or maintenance reasons.

- Potential for Hazardous Atmospheres: Confined spaces often contain or have the potential to contain a hazardous atmosphere. This could be due to the presence of toxic chemicals, flammable gasses, or insufficient oxygen. For instance, a tank previously used to store chemicals may have residual vapors, or a poorly ventilated pit might have dangerously low levels of oxygen.

- Engulfment Hazards: Some confined spaces pose risks of engulfment where an individual could be swallowed up by materials such as grains, sand, or other similar substances. This is particularly common in silos or bins used in agricultural or industrial settings.

- Other Physical Hazards: Depending on their specific use or design, confined spaces may also present physical hazards such as unguarded machinery, exposed live wires, or heat stress conditions which are exacerbated by poor ventilation.

Confined Spaces Standards and Regulations

Standards and regulations governing confined spaces ensure safety and health in industrial workplaces. These regulations are designed to protect workers who may be exposed to dangerous conditions while working in confined spaces.

| Standard/Regulation | Description |

| OSHA 29 CFR 1910.146 | Specifies requirements for permit-required confined spaces in general industry, focusing on safety procedures and worker protection |

| OSHA 29 CFR 1926 Subpart AA | Provides guidelines for confined spaces in construction, addressing unique hazards specific to construction activities. |

| NFPA 350 | Offers guidance on safe confined space entry and work, aiming to provide best practices beyond compliance. |

| ANSI Z117.1 | Establishes safety requirements for entering, working, and exiting confined spaces at normal atmospheric pressure. |

| ISO 9001 | Focuses on quality management systems which can include safety protocols such as those for confined spaces under operational risk management. |

| ISO 45001 | A framework for occupational health and safety management systems, improving safety and reducing workplace risks, applicable to confined spaces. |

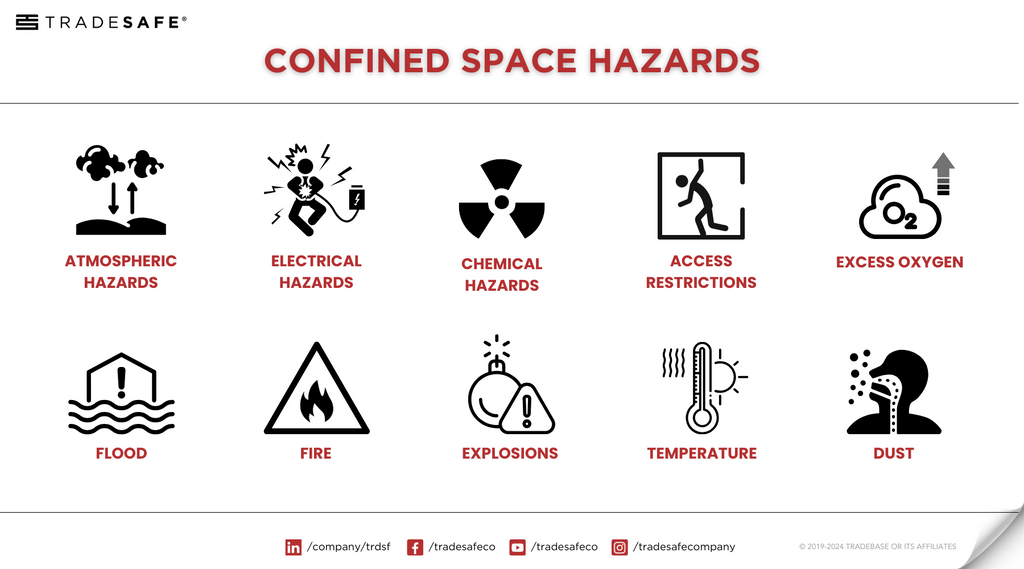

10 Major Confined Space Hazards

Building on our understanding of what a confined space is and the regulations that govern them, it's crucial to recognize the physical and atmospheric hazards that can make these environments dangerous. Awareness and preparedness are key to managing these risks effectively. Hazards associated with confined spaces include:

- Atmospheric Hazards - Atmospheric hazards in confined spaces include toxic gasses, vapors, or insufficient oxygen levels. These hazards arise from both the nature of the stored materials and the external environment. Exposure to harmful gasses can lead to health complications, unconsciousness, or death. Oxygen-deficient environments can cause asphyxiation rapidly.

- Electrical Hazards - Electrical hazards occur due to exposed wires, conductive materials, or operational electrical equipment within the confined space. Electrocution or electrical burns are significant risks, particularly in wet conditions or where protective measures like grounding are not in place.

- Chemical Exposures - Workers in confined spaces may be exposed to hazardous chemicals in the form of solids, liquids, or gasses, which can be part of the process materials or residues. Chemical burns, poisoning, and long-term health effects such as cancer or organ damage can occur depending on the toxicity and exposure level.

- Access Restrictions - Confined spaces often have limited access, which can impede both entry and exit in emergencies. Delayed emergency response and difficulty in rescuing or evacuating workers quickly, increasing the severity of any incident that occurs.

- Fire - The risk of fire is elevated in confined spaces due to limited ventilation, which can enhance the flammability of materials and gasses. Fires in confined spaces are particularly dangerous due to rapid spread and intense heat, compounded by difficulties in escape and firefighting.

- Flood - Flooding can occur in confined spaces from internal sources like pipe bursts or external sources like heavy rainfall. Drowning, hypothermia, and exposure to water-borne contaminants are primary concerns, along with potential damage to equipment.

- Excess Oxygen - High levels of oxygen in a confined space can be as dangerous as low levels, particularly due to the increased risk of fire and explosion. Elevated oxygen levels can cause materials that are normally non-flammable to ignite easily and burn intensely.

- Explosions - Confined spaces can accumulate flammable gasses, vapors, or dust, which can lead to explosions if ignited. Explosions can cause severe injury or death and significant structural damage, complicating rescue and recovery efforts.

- Temperature - Extreme temperatures, either high or low, are a common hazard in confined spaces, influenced by external conditions or internal operations. Heat can lead to heat stroke and dehydration, while cold conditions can cause hypothermia and frostbite.

- Dust - Accumulation of combustible dust in confined spaces is a significant hazard, particularly in industries dealing with grains, flour, or certain metals. Combustible dust can lead to respiratory issues or, more critically, dust explosions.

Confined Space Requirements: Safety Protocol Key Elements

Below are the critical elements of safety protocols necessary for confined space operations.

Access and Egress

Proper access and egress are critical when working in confined spaces. These spaces often have limited entry points, making it essential to ensure that entryways are clear, easily accessible, and properly marked. Additionally, workers should have a clear plan for safe exit in the event of an emergency. This includes ladders, platforms, or harnesses that can assist in the efficient evacuation of workers if needed.

Competence, Training, Supervision, and Suitability

Safety in confined spaces starts with ensuring that all personnel involved are competent and well-trained. This includes not just the workers entering the space but also those supervising and involved in rescue operations. This emphasizes the need for comprehensive training that cover critical aspects such as hazard recognition, equipment use, emergency procedures, and specific job tasks.

In addition, adequate supervision must be provided to ensure that safety procedures are followed meticulously. Supervisors need to be experienced and capable of recognizing early signs of trouble. Furthermore, it is crucial to evaluate the physical and psychological suitability of workers for working in confined spaces. This includes assessing their ability to wear required personal protective equipment and perform tasks under physically constrained and potentially stressful conditions.

Permit-to-Work Procedure

The permit-to-work is a formal written system used to control work in confined spaces and ensure that all elements of the safety protocol are in place before entry is allowed. Permit space must follow the following confined space regulations:

- Clear Description of Work: The permit must clearly describe the work to be done, the hazards involved, and the measures to mitigate these hazards.

- Safety Checks: Before a permit is issued, a series of safety checks must be completed. This includes testing atmospheric conditions, ensuring all equipment is functional, and confirming that emergency procedures are set.

- Sign-off by Authorities: The permit must be signed off by the designated safety officer or supervisor. This signifies that all safety measures meet the required standards and that it is safe to proceed.

- Time Bound: Permits are strictly time-bound. They are only valid for the duration of the specific job or shift and must be renewed for additional work.

- Closure and Review: Once the task is completed, the permit should be formally closed with a debrief and review to ensure any learning points are captured and future safety is enhanced.

Communications

Robust communication systems are essential in confined spaces due to the isolation of these areas and potential barriers caused by structural elements. Strategies often include the use of reliable two-way communication devices that can operate effectively in confined settings if necessary to maintain constant contact between the workers inside and the team outside, the establishment of predetermined emergency communication plans, and the implementation of regular check-ins during operations.

Gas Purging and Ventilation

Gas purging and ventilation are critical procedures designed to mitigate atmospheric hazards in confined spaces. Enclosed spaces produce dangerous air contaminants that pose risks of asphyxiation, fire, or explosion. This process ensures that harmful gasses in the atmosphere are removed and replaced with fresh air, minimizing risk and ensuring safe air circulation in the area. This involves displacing hazardous gasses and vapors from the confined space with an inert gas, typically nitrogen, with the goal to minimize the oxygen level to prevent combustion and to eliminate any toxic substances from the atmosphere.

Dangerous Residues

Dangerous residues, whether chemical, biological, or radiological, can pose severe health risks to individuals entering confined spaces. Before entry, all residues must be identified, and their potential hazards assessed. This includes understanding the chemical nature of residues and their possible reactions.

Whenever possible, residues should be removed or neutralized before entry. If removal is not feasible, appropriate protective measures must be taken to safeguard workers from exposure. In addition, appropriate PPE must be worn by all entrants to protect against specific hazards posed by the residues. This might include respirators, gloves, and chemical-resistant clothing.

Testing and Monitoring of the Atmosphere

Testing and monitoring the atmosphere in confined spaces are essential to detect invisible threats such as toxic gasses, explosive limits, and oxygen deficiency or enrichment. Before entry, the atmosphere should be tested from outside the confined space using portable gas detectors to determine if it is safe to enter. The atmosphere in a confined space should also be continuously monitored to alert workers of any changes in atmospheric conditions that could indicate developing hazards.

Mechanical, Electrical, and Process Isolation

Isolation of mechanical, electrical, and process systems is essential to prevent unintended energization or release of hazardous substances into confined spaces. Mechanical isolation involves physically disconnecting machinery and equipment from their power sources, typically through lockout/tagout (LOTO) procedures, to prevent accidental startup. Electrical isolation is achieved by disconnecting electrical power entirely and locking out the switches while process isolation involves closing and locking valve systems to prevent the flow of gasses, liquids, or solids into the confined space.

Respiratory Protective Equipment (RPE)

In environments where ventilation is insufficient to ensure breathable air, Respiratory Protective Equipment is crucial to protect workers from inhaling harmful contaminants.

- Air-Purifying Respirators: Suitable for environments where the air quality is compromised but contains enough oxygen to breathe safely. These respirators use filters or cartridges to remove contaminants.

- Air-Supplying Respirators: Used in oxygen-deficient atmospheres or where unknown hazards exist. These include self-contained breathing apparatus (SCBA) or airline respirators that provide a safe, external source of breathable air.

- Fit Testing and Maintenance: Regular fit testing is essential to ensure a tight seal and effective protection. Maintenance, cleaning, and storage of RPE must follow manufacturer guidelines to ensure their reliability and performance.

Other Personal Protective Equipment (PPE)

While respiratory protection is critical, other types of PPE are equally important to ensure the safety of workers from head to toe. This includes the use of protective clothing from head to toe, eye and face protection, hearing protection, and head protection to ensure worker health and safety while working in confined spaces.

Safe Use of Work Equipment

In confined spaces, the correct and safe use of work equipment is crucial not only for the task at hand but also for the safety of the workers involved. All equipment used in confined spaces must be specifically suitable for the intended tasks and the environmental conditions of the space. These should also be regularly inspected and maintained according to manufacturer's guidelines to ensure it remains in safe working condition. Furthermore, workers must receive thorough training on the correct use of each piece of equipment.

Confined Space Entry: Best Practices

Before entering a confined space, strict protocols and requirements must be followed to minimize risks. This entry protocol ensures that no worker enters the space without proper preparation and precaution.

Confined Space Training

Proper confined space training significantly reduces the risk of accidents and fatalities. Workers who understand the hazards and are equipped with the right skills are better prepared to avoid mistakes and respond appropriately to emergencies. Considering this, here are the key topics and elements that should be included in a comprehensive confined space training program:

- Hazard Identification: Workers are trained to recognize hazards in confined spaces, such as toxic gases, low oxygen, and mechanical risks, using tools like gas detectors and assessing potential dangers.

- Use of Personal Protective Equipment (PPE): Training ensures workers know how to select, use, inspect, and maintain PPE like respirators, protective suits, and harnesses to protect against specific confined space hazards.

- Safe Entry and Exit Procedures: Workers learn how to safely enter and exit confined spaces using proper access equipment like ladders and harnesses, and secure entry points to prevent unauthorized access.

- Emergency Response and Rescue Procedures: Training covers how to react during emergencies, use rescue equipment, and assist in rescues without causing further harm.

- Atmospheric Testing and Monitoring: Workers are trained to use gas detectors to test for oxygen levels, flammable gases, and toxic substances, with continuous monitoring when necessary.

- Lockout/Tagout Procedures: Training covers isolating hazardous energy sources by properly locking and tagging out mechanical, electrical, and chemical systems to prevent accidental activation.

- Communication Protocols: Workers are trained on using radios or signals to maintain communication with team members and supervisors, especially during emergencies.

- Roles and Responsibilities: Training clarifies the duties of all personnel involved in confined space work, including entrants, attendants, and supervisors, ensuring coordinated safety measures.

- Refresher Training: Periodic refresher training is essential to keep workers updated on confined space safety procedures, regulations, and equipment advancements.

Confined Space Hazard Assessment

Hazard assessment is a confined space pre-entry step aimed at determining potential risks and dangers that can result in serious injury or death if not properly identified and mitigated. Here is an overview of the necessary steps taken in identifying confined space hazards:

- Oxygen-Deficient Atmospheres: Identified using an oxygen meter to test the atmosphere for oxygen levels before entry, with continuous monitoring if levels are unstable.

- Flammable Atmospheres: Detected by using a gas detector to check for flammable gases like methane or propane before entry into the confined space.

- Toxic Atmospheres: Identified through gas detectors that monitor for toxic gases such as hydrogen sulfide or carbon monoxide, both before and during the operation.

- Mechanical and Physical Hazards: Assessed by inspecting the space for entrapment, crush points, moving machinery, and unstable structures, along with applying lockout/tagout procedures to prevent accidental activation.

Confined Space Isolation

Confined space isolation is a critical safety step that involves disconnecting and de-energizing all potential sources of hazards, such as machinery, electrical systems, and hazardous materials, before workers enter the space. The goal of isolation is to eliminate the risk of accidental exposure to harmful substances, unexpected mechanical movements, or the activation of hazardous energy sources while work is being performed.

Confined space isolation typically involves several key procedures to ensure that hazardous energy sources are properly controlled:

Lockout/Tagout (LOTO) Procedures

- Identify energy sources: Before any confined space entry, all sources of hazardous energy must be identified. This includes electrical circuits, hydraulic or pneumatic systems, and any other form of energy that could pose a danger.

- De-energize the equipment: Once identified, energy sources must be shut down, de-energized, or disconnected. This step eliminates the risk of unexpected movements or releases.

- Lock and tag the equipment: After de-energizing the equipment, apply locks and tags to ensure the systems cannot be restarted. Each worker involved should place their own lock, ensuring that only they can remove it once the task is complete.

- Verify isolation: Before entering the confined space, it’s essential to verify that the equipment is properly isolated. This may involve testing electrical circuits to confirm they are de-energized or checking that mechanical parts cannot move.

- Complete the work and remove locks/tags: Once the confined space work is completed, only the workers who applied the locks or tags can remove them, ensuring that the system can be safely re-energized once everyone is clear.

Physical Disconnection

For confined spaces that have connections to pipelines or ducts carrying hazardous materials, physical disconnection or blinding may be required. This involves physically removing a section of the pipe or inserting a metal plate (blind) between sections to ensure that no fluids or gases can enter the space while work is being performed. This is especially important in spaces where hazardous liquids or gases could flow into the confined space, posing risks of poisoning, explosions, or chemical burns.

Securing Heat-Producing Equipment

Confined spaces may also contain heat-producing equipment, such as furnaces or heating elements, which could pose burn or fire hazards. Before entry, this equipment must be fully disconnected and allowed to cool down. In addition, workers must ensure that any potential sources of ignition are controlled in environments where flammable gases or vapors are present.

Use of Double Block and Bleed Systems

In some situations, particularly in the petrochemical and oil industries, a double block and bleed system may be used for isolation. This involves closing two valves in sequence on a pipeline and then draining any material between the valves to ensure complete isolation. This technique provides an added layer of safety by ensuring that even if one valve fails, the second will prevent hazardous materials from entering the confined space.

Confined Space Safety Tools and Equipment

Having the right tools and equipment is essential for ensuring the safety of workers operating in confined spaces. This includes not only personal protective and emergency equipment but also devices designed to control hazardous energies and inform personnel of potential dangers.

- Gas Detectors - Essential for continuous monitoring of atmospheric hazards such as toxic gasses, flammable vapors, and oxygen deficiency. These detectors can provide early warning alerts to prevent health risks or fatal incidents.

- Ventilation Equipment - Portable mechanical ventilation systems help maintain breathable air quality and can be crucial in removing or diluting hazardous atmospheres within confined spaces.

- Personal Protective Equipment (PPE) - Comprehensive PPE may include respirators, protective suits, gloves, helmets, and boots, tailored to protect against specific hazards identified in the risk assessment.

- Communication Devices - Devices that are intrinsically safe and capable of maintaining clear communications in environments with structural interferences are vital for coordinating operations and ensuring safety in emergencies.

- Rescue and Emergency Equipment - Equipment such as rescue tripods, winches, and retrieval lines are critical for providing a means of rapid extraction in case of an emergency, ensuring that rescue operations can be executed swiftly and safely.

- Lockout/Tagout (LOTO) Devices - LOTO devices are crucial for ensuring that all mechanical and electrical equipment associated with the confined space is de-energized and remains inoperative while work is being performed. This prevents accidental start-up of machinery which could lead to injuries.

- Safety and Warnings Signs - Workplace signs play a critical role in warning about the hazards, indicating the nature of the confined space, and providing instructions or prohibitions specific to the site.

Ensuring safety during confined space entry requires adherence to strict protocols, including obtaining a confined space permit, conducting initial and periodic tests of the confined space environment, and completing a comprehensive confined space course. Each particular confined space presents unique hazards, making compliance with the OSHA confined space standard essential and critical.

FAQs

What are the three types of confined spaces?

The three types of confined spaces are non-permit required confined spaces, permit-required confined spaces, and enclosed spaces with hazardous atmospheres or physical dangers.

What is the normal oxygen level in a confined space?

The normal oxygen level in a confined space is between 19.5% and 23.5%.

What PPE is required for confined space entry?

Required PPE for confined space entry may include respiratory protection, hard hats, protective suits, gloves, safety boots, and harnesses.

What is the maximum allowable temperature for confined space entry?

The maximum allowable temperature for confined space entry typically should not exceed 104°F (40°C), but this can vary depending on the task and regulatory guidelines.

What are the confined space training objectives?

The objectives of confined space training are to ensure workers understand hazard identification, safe entry and exit procedures, emergency protocols, and the proper use of PPE and rescue equipment.