-

-40%

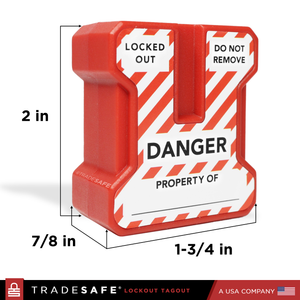

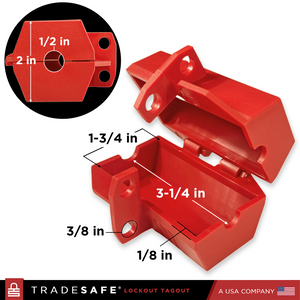

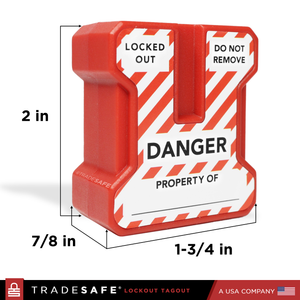

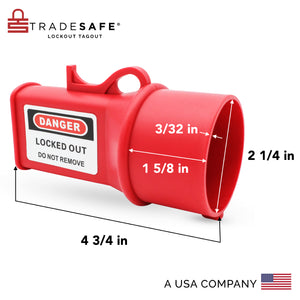

Plug Lockout Device - 110V-125V - Small, 2 Pack

Regular price $14.95Regular price$24.95-40%Sale price $14.95 -

-44%

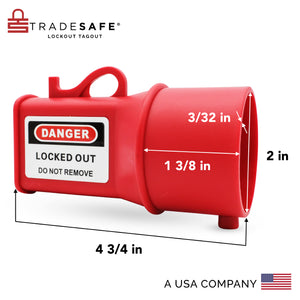

Plug Lockout Device - 110 to 125V - Medium

Regular price $13.95Regular price$24.95-44%Sale price $13.95 -

-48%

Plug Lockout Device - 110V-125V - Medium, 2 Pack

Regular price $25.95Regular price$50.00-48%Sale price $25.95 -

-37%

Plug Lockout Device - 220V - Large

Regular price $18.95Regular price$29.95-37%Sale price $18.95 -

-50%

Plug Lockout Device - 220V - Large, 2 Pack

Regular price $34.95Regular price$70.00-50%Sale price $34.95 -

-43%

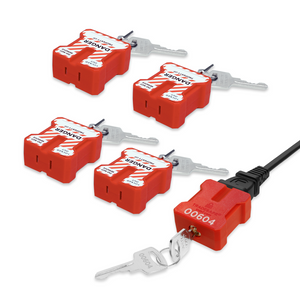

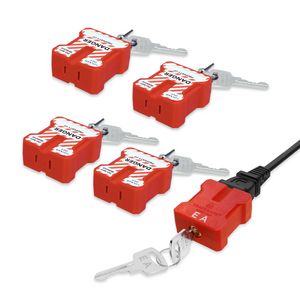

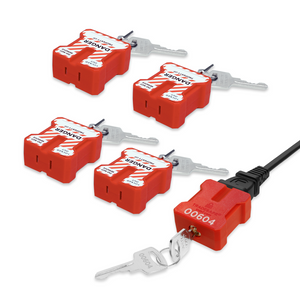

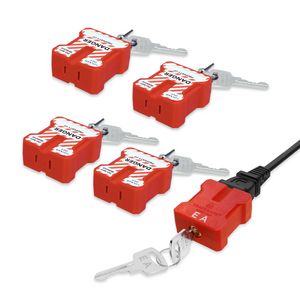

Power Plug Lock Keyed Different - 5 Pack - 2 Keys Each

Regular price $84.95Regular price$150.00-43%Sale price $84.95 -

-43%

Power Plug Lock Keyed Alike Unlimited - 5 Pack - 2 Keys Each

Regular price $84.95Regular price$150.00-43%Sale price $84.95 -

-39%

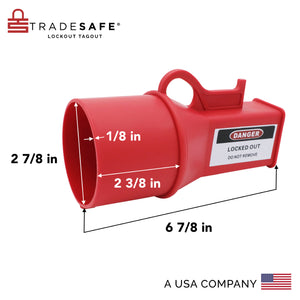

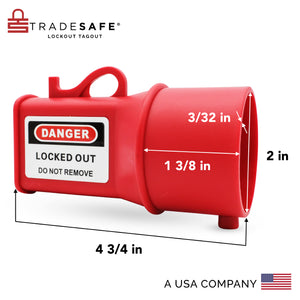

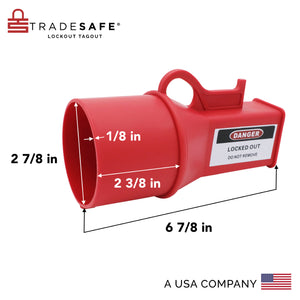

Pin and Sleeve Socket Lockout Device – 2-7/8” Diameter

Regular price $29.95Regular price$49.00-39%Sale price $29.95 -

-49%

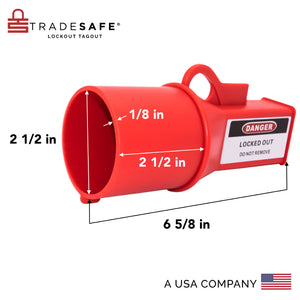

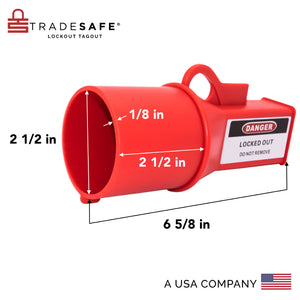

Pin and Sleeve Socket Lockout Device – 2-1/2” Diameter

Regular price $24.95Regular price$49.00-49%Sale price $24.95 -

-49%

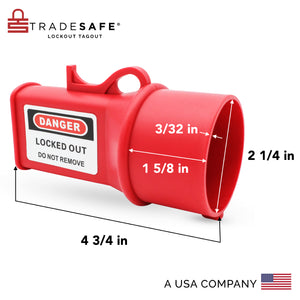

Pin and Sleeve Socket Lockout Device – 2-1/4” Diameter

Regular price $24.95Regular price$49.00-49%Sale price $24.95 -

-49%

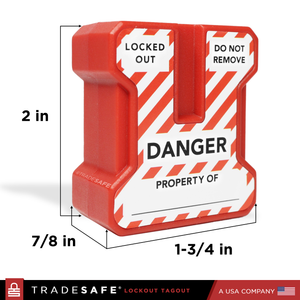

Pin and Sleeve Socket Lockout Device – 2” Diameter

Regular price $19.95Regular price$39.00-49%Sale price $19.95 -

-49%

Pin and Sleeve Socket Lockout Device – 1 1/2” Diameter

Regular price $19.95Regular price$39.00-49%Sale price $19.95

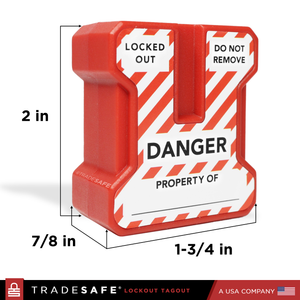

When you work with electric machines and equipment, one of the most effective ways to prevent accidental re-energizing is to cut these machines off from their power source. Simply unplugging them from their sockets during maintenance and repair will not be enough, as anyone can pass by and plug them back in.

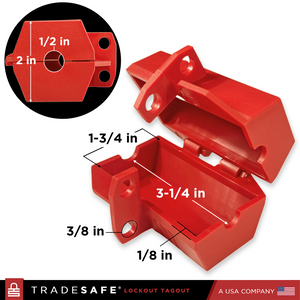

Thus, plug and socket lockout devices can ensure that machines will not be plugged back in while maintenance and repairs are ongoing. Plug lockout devices encase plugs and are locked with LOTO locks, thus making it physically impossible for anyone to plug a machine back in until the lockout is removed. Socket lockouts, meanwhile, go over electrical sockets and can prevent the machines in an entire area from being plugged back in.

These lockout devices are essential to electrical lockout tagout procedures. They are simple and easy to install but will be very difficult to remove by unauthorized personnel. Because they’re made of durable and impact-resistant material, they won’t twist, bend, or break without extraordinary force.