-

-49%

Lockout Tagout Station – Medium

Regular price $109.95Regular price$215.00-49%Sale price $109.95 -

-31%

Lockout Tagout Station – Large

Regular price $169.95Regular price$245.00-31%Sale price $169.95 -

-40%

Lockout Tagout Station - XL

Regular price $199.99Regular price$335.00-40%Sale price $199.99 -

-25%

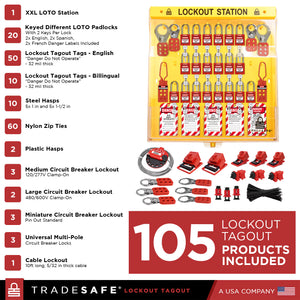

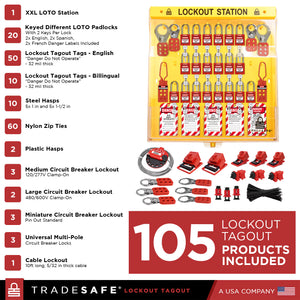

Lockout Tagout Station - XXL

Regular price $399.95Regular price$529.95-25%Sale price $399.95 -

-42%

Lockout Tagout Station - No LOTO Devices Included

Regular price $77.95Regular price$135.00-42%Sale price $77.95 -

-28%

Lockout Tagout Station - XXL - No LOTO Devices Included

Regular price $179.95Regular price$249.95-28%Sale price $179.95 -

-16%

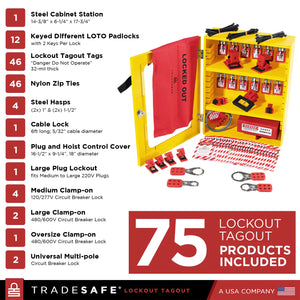

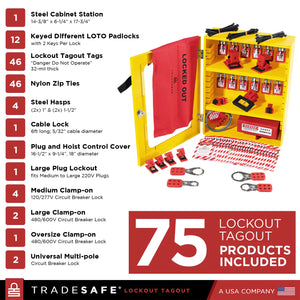

Lockout Tagout Cabinet - 75 Devices

Regular price $420.95Regular price$499.00-16%Sale price $420.95 -

-36%

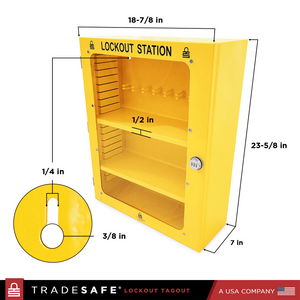

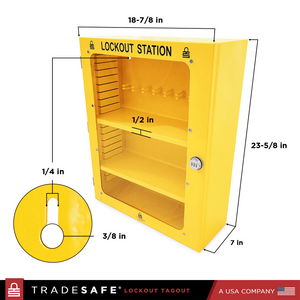

Lockout Tagout Cabinet - LOTO Devices Not Included - Large

Regular price $189.95Regular price$299.00-36%Sale price $189.95 -

-14%

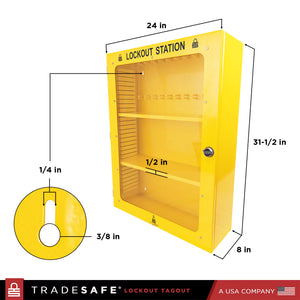

Lockout Tagout Cabinet - LOTO Devices Not Included - XL

Regular price $299.95Regular price$349.95-14%Sale price $299.95 -

-20%

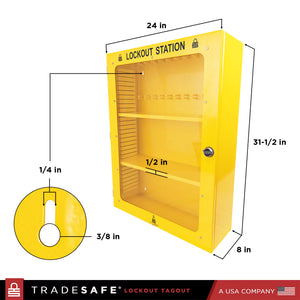

Lockout Tagout Cabinet - LOTO Devices Not Included - XXL

Regular price $389.95Regular price$489.95-20%Sale price $389.95 -

-23%

Lockout Tagout Cabinet - 80 Devices - Keyed Different

Regular price $369.95Regular price$479.95-23%Sale price $369.95 -

-23%

Lockout Tagout Cabinet - 80 Devices - Keyed Alike Unlimited

Regular price $369.95Regular price$479.95-23%Sale price $369.95 -

-33%

Lockout Tagout Cabinet - LOTO Devices Not Included

Regular price $159.95Regular price$239.95-33%Sale price $159.95 -

-36%

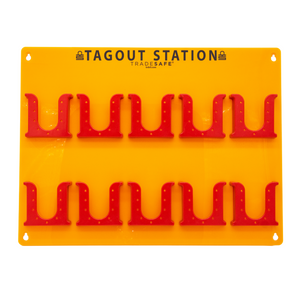

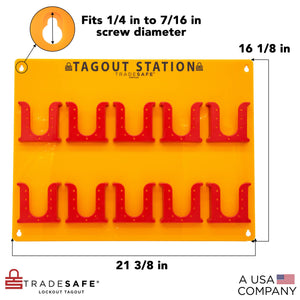

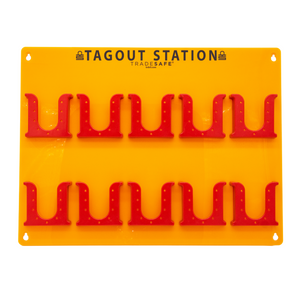

Lockout Tagout Station for LOTO Tags – 150 Tags Included

Regular price $189.95Regular price$299.00-36%Sale price $189.95 -

-65%

Lockout Tagout Station for LOTO Tags - Tags Not Included

Regular price $69.95Regular price$199.00-65%Sale price $69.95 -

-23%

Safety Padlock Station - 20 Lockout Tagout Locks Included

Regular price $153.95Regular price$199.00-23%Sale price $153.95 -

-21%

Safety Padlock Lockout Tagout Station - Fits 20 Padlocks – LOTO Locks Not Included

Regular price $38.95Regular price$49.00-21%Sale price $38.95 -

-45%

Safety Padlock Station - 10 Lockout Tagout Locks Included

Regular price $75.95Regular price$139.00-45%Sale price $75.95 -

-30%

Safety Padlock Lockout Tagout Station – Fits 10 Padlocks – LOTO Locks Not Included

Regular price $27.95Regular price$39.95-30%Sale price $27.95 -

-41%

Portable Safety Padlock Storage – Fits 12 Lockout Padlocks

Regular price $22.95Regular price$39.00-41%Sale price $22.95

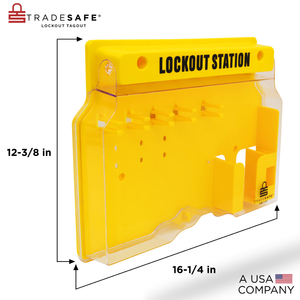

Keeping lockout tagout devices consistently organized and in one place can help improve workplace safety and ensure compliance with OSHA standards. Lockout tagout stations can provide a reliable and highly visible place to store and organize any and all lockout devices and supplies.

TRADESAFE understands the need for organization and the establishment of routine procedures in lockout tagout programs. These lockout stations can help employees easily and intuitively execute procedures because all the devices involved can reliably be found in one place.

You can also strategically place LOTO stations in visible and convenient spots near machine switches or in central areas. All our lockout tagout stations come with a variety of devices and supplies. Not only are these stations highly useful, but they’re also a great bargain.