-

-75%

Oversized Plug and Hoist Control Cover, Fits 18” Controls

Regular price $24.95Regular price$100.00-75%Sale price $24.95 -

-27%

Lockout Tagout Tool Box Kit - 85 LOTO Devices

Regular price $239.95Regular price$329.95-27%Sale price $239.95 -

-26%

Valve Lockout Tagout Kit - 55 LOTO Devices

Regular price $319.95Regular price$429.95-26%Sale price $319.95 -

-25%

Complete Electrical Lockout Tagout Kit - 90 LOTO Devices

Regular price $299.95Regular price$399.95-25%Sale price $299.95 -

-20%

Ultimate Lockout Tagout Kit - 95 LOTO Devices

Regular price $439.95Regular price$549.95-20%Sale price $439.95 -

-54%

Electrical Lockout Tagout Kit – 1 Key Per Lock

Regular price $68.95Regular price$149.00-54%Sale price $68.95 -

-54%

Electrical Lockout Tagout Kit – 2 Keys Per Lock

Regular price $68.95Regular price$149.00-54%Sale price $68.95 -

-62%

Complete Breaker Lockout Tagout Kit – 1 Key Per Lock

Regular price $79.90Regular price$209.00-62%Sale price $79.90 -

-62%

Complete Breaker Lockout Tagout Kit – 2 Keys Per Lock

Regular price $79.90Regular price$209.00-62%Sale price $79.90 -

-56%

Professional Lockout Tagout Kit – 2 Keys Per Lock

Regular price $84.95Regular price$193.00-56%Sale price $84.95 -

-56%

Professional Lockout Tagout Kit – 1 Key Per Lock

Regular price $84.95Regular price$193.00-56%Sale price $84.95 -

-62%

Personal Lockout Tagout Kit – 1 Key Per Lock

Regular price $41.95Regular price$110.00-62%Sale price $41.95 -

-62%

Personal Lockout Tagout Kit – 2 Keys Per Lock

Regular price $41.95Regular price$110.00-62%Sale price $41.95 -

-40%

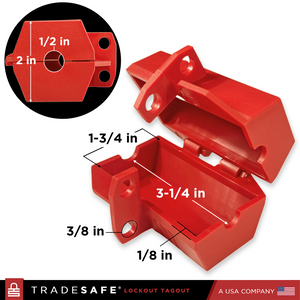

Plug Lockout Device - 110V-125V - Small, 2 Pack

Regular price $14.95Regular price$24.95-40%Sale price $14.95 -

-44%

Plug Lockout Device - 110 to 125V - Medium

Regular price $13.95Regular price$24.95-44%Sale price $13.95 -

-48%

Plug Lockout Device - 110V-125V - Medium, 2 Pack

Regular price $25.95Regular price$50.00-48%Sale price $25.95 -

-37%

Plug Lockout Device - 220V - Large

Regular price $18.95Regular price$29.95-37%Sale price $18.95 -

-50%

Plug Lockout Device - 220V - Large, 2 Pack

Regular price $34.95Regular price$70.00-50%Sale price $34.95 -

-43%

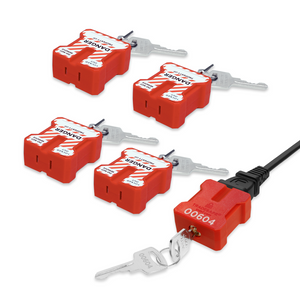

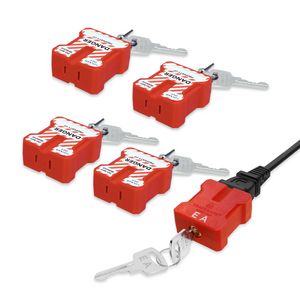

Power Plug Lock Keyed Different - 5 Pack - 2 Keys Each

Regular price $84.95Regular price$150.00-43%Sale price $84.95 -

-43%

Power Plug Lock Keyed Alike Unlimited - 5 Pack - 2 Keys Each

Regular price $84.95Regular price$150.00-43%Sale price $84.95 -

-42%

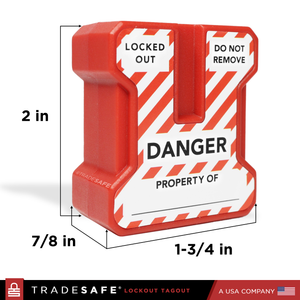

Clamp-on Circuit Breaker Lockout Device – 120/277 Volt – 10 Pack

Regular price $69.95Regular price$120.00-42%Sale price $69.95 -

-53%

Clamp-on Circuit Breaker Lockout Device – 480/600 Volt – 3 Pack

Regular price $27.95Regular price$60.00-53%Sale price $27.95 -

-50%

Clamp-on Circuit Breaker Lockout Device – Oversized 480/600 Volt – 3 Pack

Regular price $34.95Regular price$70.00-50%Sale price $34.95 -

Sold out

Universal Circuit Breaker Lockout Device - up to 7/8" Tie Bar – 10 Pack

Regular price $78.95Regular price$130.00-39%Sale price $78.95 -

-29%

Miniature Circuit Breaker Lockout Device - Pin In Standard (PIS) - 3 Pack

Regular price $16.95Regular price$24.00-29%Sale price $16.95 -

-29%

Miniature Circuit Breaker Lockout Device - Pin Out Standard (POS) - 3 Pack

Regular price $16.95Regular price$24.00-29%Sale price $16.95 -

-29%

Miniature Circuit Breaker Lockout Device - Pin Out Wide (POW) - 3 Pack

Regular price $16.95Regular price$24.00-29%Sale price $16.95 -

-29%

Miniature Circuit Breaker Lockout Device - Tie Bar Lockout (TBLO) - 3 Pack

Regular price $16.95Regular price$24.00-29%Sale price $16.95 -

-40%

Circuit Breaker Lockout – Breaker Blocker Kit – 480/600 Volt

Regular price $29.95Regular price$50.00-40%Sale price $29.95 -

-70%

Medium Push Button Lockout – Round – 5 Pack

Regular price $35.80Regular price$120.00-70%Sale price $35.80 -

-64%

Large Push Button Lockout – Round – 5 Pack

Regular price $43.80Regular price$120.00-64%Sale price $43.80 -

-49%

Push Button Lockout - Round - 3-Piece Set

Regular price $29.95Regular price$59.00-49%Sale price $29.95 -

-49%

Push Button Lockout - Box Type - Medium

Regular price $29.95Regular price$59.00-49%Sale price $29.95 -

-49%

Push Button Lockout - Box Type - Large

Regular price $39.95Regular price$79.00-49%Sale price $39.95 -

-49%

Push Button Lockout - Box Type - XL

Regular price $44.95Regular price$89.00-49%Sale price $44.95 -

-49%

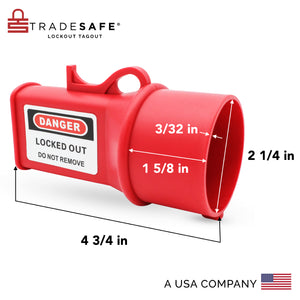

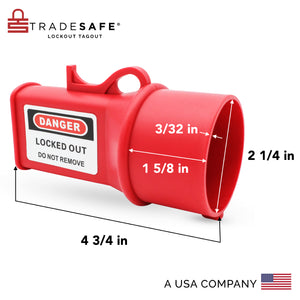

Pin and Sleeve Socket Lockout Device – 1 1/2” Diameter

Regular price $19.95Regular price$39.00-49%Sale price $19.95 -

-49%

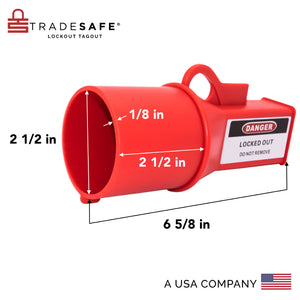

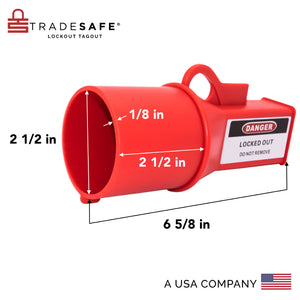

Pin and Sleeve Socket Lockout Device – 2” Diameter

Regular price $19.95Regular price$39.00-49%Sale price $19.95 -

-49%

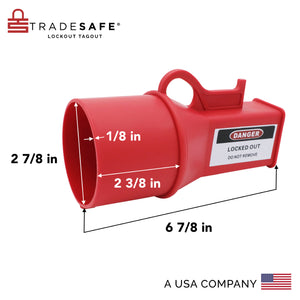

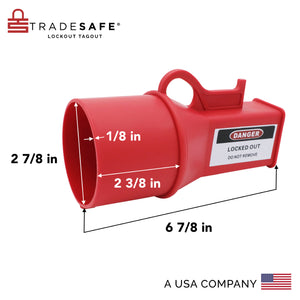

Pin and Sleeve Socket Lockout Device – 2-1/4” Diameter

Regular price $24.95Regular price$49.00-49%Sale price $24.95 -

-49%

Pin and Sleeve Socket Lockout Device – 2-1/2” Diameter

Regular price $24.95Regular price$49.00-49%Sale price $24.95 -

-39%

Pin and Sleeve Socket Lockout Device – 2-7/8” Diameter

Regular price $29.95Regular price$49.00-39%Sale price $29.95 -

-61%

Lockout Tagout Hasp with 6 Padlock Holes – Polypropylene – 3 Pack

Regular price $14.95Regular price$38.00-61%Sale price $14.95 -

-47%

Lockout Tagout Hasp – Nylon and Steel, 1" Jaw Diameter, 6 Pack

Regular price $35.95Regular price$68.00-47%Sale price $35.95 -

-42%

Lockout Tagout Hasp – Nylon and Steel, 1-1/2" Jaw Diameter, 6 Pack

Regular price $45.95Regular price$79.00-42%Sale price $45.95 -

-30%

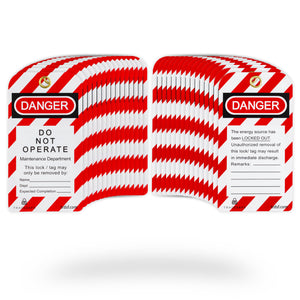

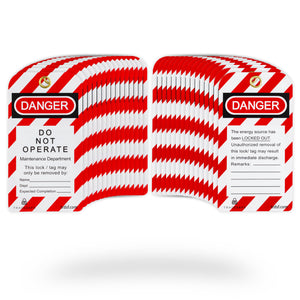

Lockout Tagout Danger Tags – Pack of 10

Regular price $20.95Regular price$30.00-30%Sale price $20.95 -

-38%

Lockout Tagout Danger Tags – Pack of 30

Regular price $36.95Regular price$60.00-38%Sale price $36.95 -

-45%

Lockout Tagout Danger Tags – Pack of 60

Regular price $65.95Regular price$120.00-45%Sale price $65.95 -

-38%

Bilingual Lockout Tagout Danger Tags – Pack of 30

Regular price $36.95Regular price$60.00-38%Sale price $36.95 -

-38%

Spanish Lockout Tagout Danger Tags – Pack of 30

Regular price $36.95Regular price$60.00-38%Sale price $36.95

Electrical lockout devices are an important component of your safety practices for keeping your workplace safe and OSHA-compliant. It protects workers from uncontrolled hazardous energy that may escape from machinery or equipment during isolation, servicing, or maintenance.

At TRADESAFE, safety is never compromised but maximized. Our collection includes a wide range of electrical lockouts available to fit plugs & sockets, valves, panels, breakers, and more. Each electrical lockout device is easy to use and made of high-quality materials that can resist the harsh and hazardous environments common in industrial facilities.

TRADESAFE only offers premium, precision-engineered lockout devices to help you meet OSHA 1910.147 (Control of Hazardous Energy) standards in your workplace while also instilling responsibility and accountability among your workers.