-

-42%

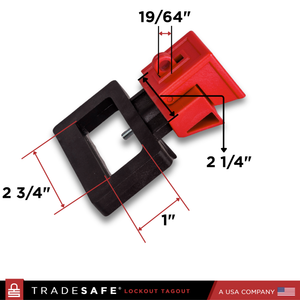

Clamp-on Circuit Breaker Lockout Device – 120/277 Volt – 10 Pack

Regular price $69.95Regular price$120.00-42%Sale price $69.95 -

-53%

Clamp-on Circuit Breaker Lockout Device – 480/600 Volt – 3 Pack

Regular price $27.95Regular price$60.00-53%Sale price $27.95 -

-50%

Clamp-on Circuit Breaker Lockout Device – Oversized 480/600 Volt – 3 Pack

Regular price $34.95Regular price$70.00-50%Sale price $34.95 -

-39%

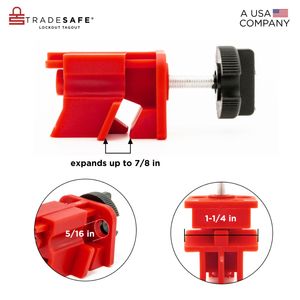

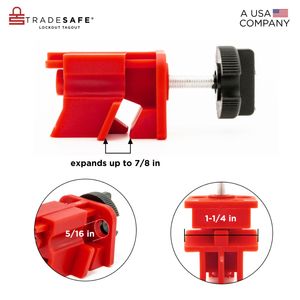

Universal Circuit Breaker Lockout Device - up to 7/8" Tie Bar – 10 Pack

Regular price $78.95Regular price$130.00-39%Sale price $78.95 -

-29%

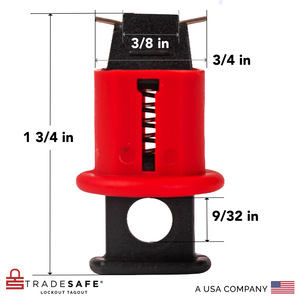

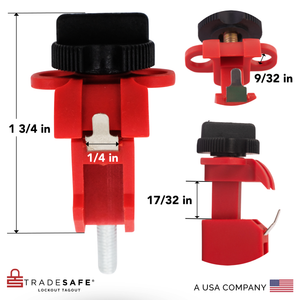

Miniature Circuit Breaker Lockout Device - Pin Out Wide (POW) - 3 Pack

Regular price $16.95Regular price$24.00-29%Sale price $16.95 -

-29%

Miniature Circuit Breaker Lockout Device - Pin In Standard (PIS) - 3 Pack

Regular price $16.95Regular price$24.00-29%Sale price $16.95 -

-29%

Miniature Circuit Breaker Lockout Device - Pin Out Standard (POS) - 3 Pack

Regular price $16.95Regular price$24.00-29%Sale price $16.95 -

-29%

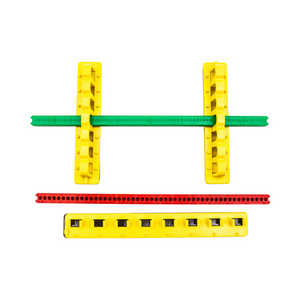

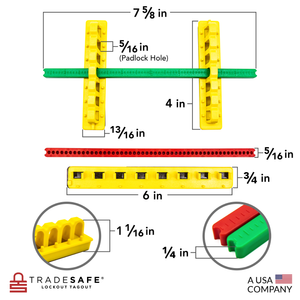

Miniature Circuit Breaker Lockout Device - Tie Bar Lockout (TBLO) - 3 Pack

Regular price $16.95Regular price$24.00-29%Sale price $16.95 -

-40%

Circuit Breaker Lockout – Breaker Blocker Kit – 480/600 Volt

Regular price $29.95Regular price$50.00-40%Sale price $29.95

Keep maintenance personnel safe and prevent workplace accidents with the right lockout tagout circuit breaker locks. TRADESAFE has a premium-quality line of locks available for both miniature circuit breakers (MCBs) and standard circuit breakers.

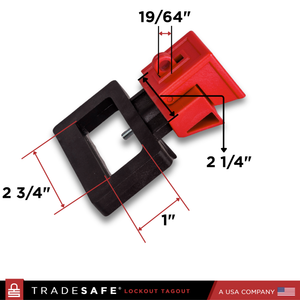

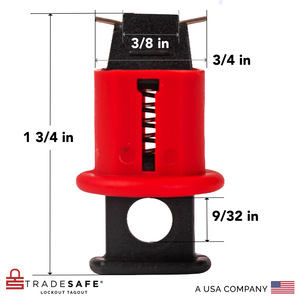

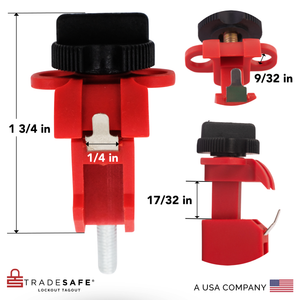

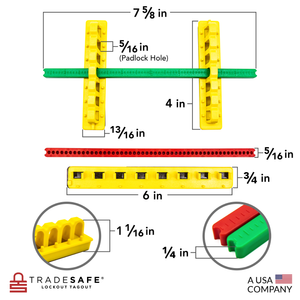

Clamp-on circuit breaker lockouts can easily secure single-pole breaker toggles that are ⅝” to 2-¾” wide and ½” to 1” thick. Meanwhile, miniature circuit breaker lockout devices come in variations, including Pin-Out Wide, Pin-In Standard, Pin-Out Standard, and Tie Bar Lockout.

TRADESAFE circuit breaker lockouts can secure breaker switches quickly and effectively - no need to worry about costly or dangerous operational or human errors. These locks are made of industrial-grade, non-conductive, and corrosion-resistant materials, guaranteeing compliance with OSHA. Plus, they are easy to install and won’t require the use of screwdrivers or any other kinds of tools.