-

-17%

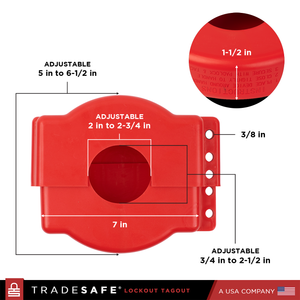

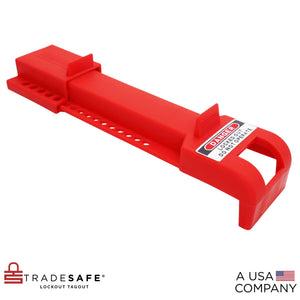

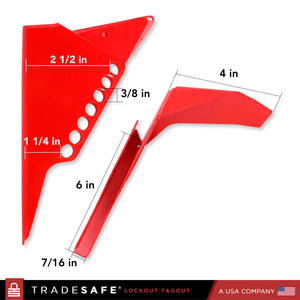

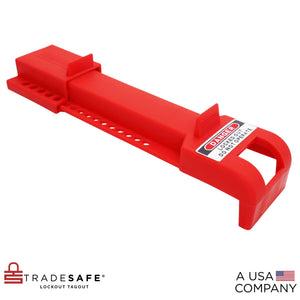

Adjustable Gate Valve Lockout - 1” to 6-1/2” Handle Diameter

Regular price $19.95Regular price$24.00-17%Sale price $19.95 -

-47%

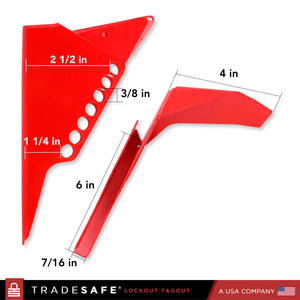

Gate Valve Lockout - 1” to 2-1/2” Handle Diameter - 2 Pack

Regular price $18.95Regular price$36.00-47%Sale price $18.95 -

-46%

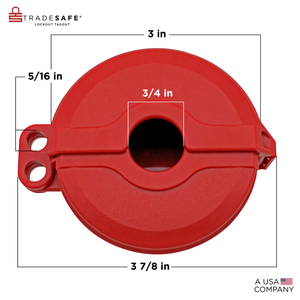

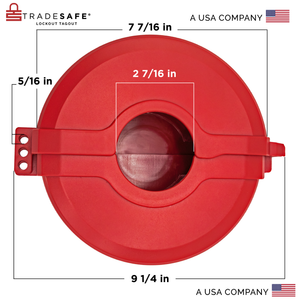

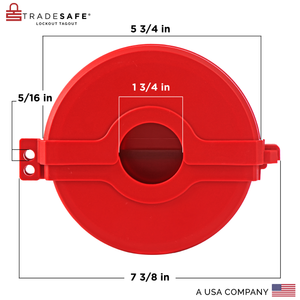

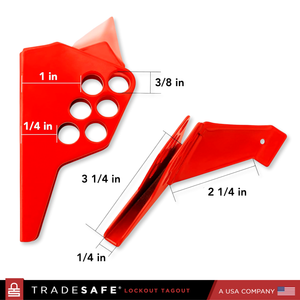

Gate Valve Lockout – 1” to 2-1/2” Valve Handle Diameter

Regular price $12.95Regular price$24.00-46%Sale price $12.95 -

-49%

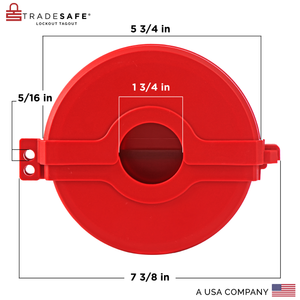

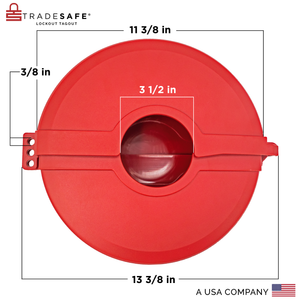

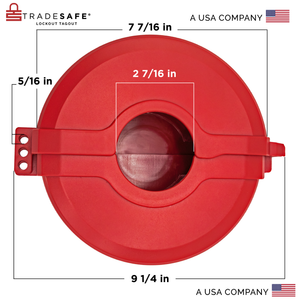

Gate Valve Lockout – 2-1/2” to 5” Valve Handle Diameter

Regular price $19.95Regular price$39.00-49%Sale price $19.95 -

-49%

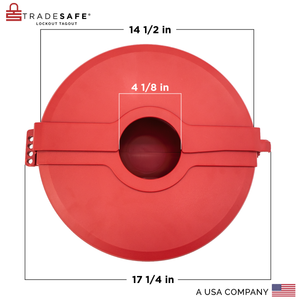

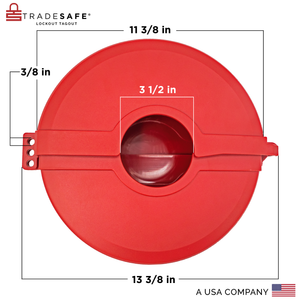

Gate Valve Lockout – 5” to 6-1/2” Valve Handle Diameter

Regular price $29.95Regular price$59.00-49%Sale price $29.95 -

-50%

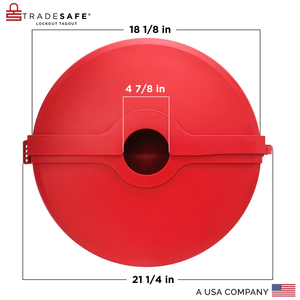

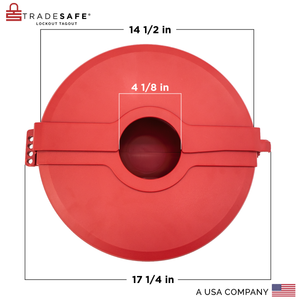

Gate Valve Lockout – 6-1/2” to 10” Valve Handle Diameter

Regular price $54.95Regular price$109.00-50%Sale price $54.95 -

-45%

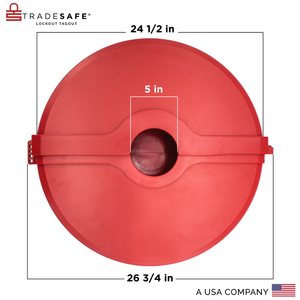

Gate Valve Lockout – 10” to 13” Valve Handle Diameter

Regular price $64.95Regular price$119.00-45%Sale price $64.95 -

-42%

Gate Valve Lockout – 13” to 18” Valve Handle Diameter

Regular price $79.95Regular price$139.00-42%Sale price $79.95 -

-33%

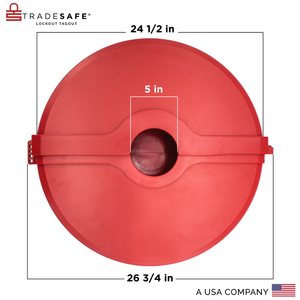

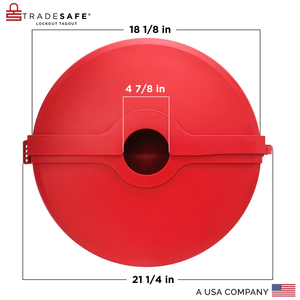

Gate Valve Lockout – 18” to 24” Valve Handle Diameter

Regular price $139.95Regular price$209.00-33%Sale price $139.95 -

-48%

Adjustable Flanged Ball Valve Lockout - Fits 2” to 4-1/2” Valves

Regular price $35.95Regular price$69.00-48%Sale price $35.95 -

-40%

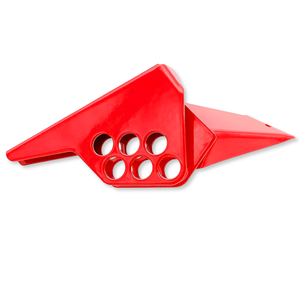

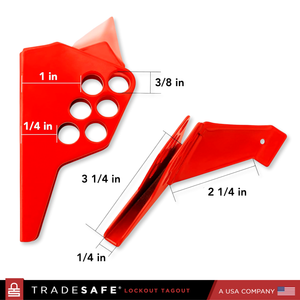

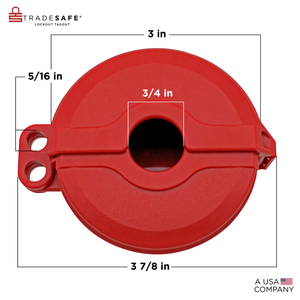

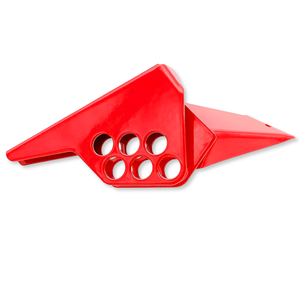

Butterfly Valve Lockout - 3 11/32” Valve Head Diameter

Regular price $29.95Regular price$50.00-40%Sale price $29.95 -

-52%

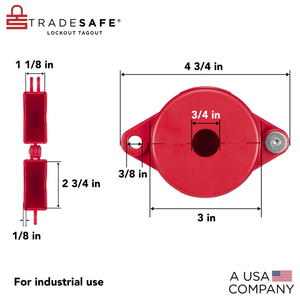

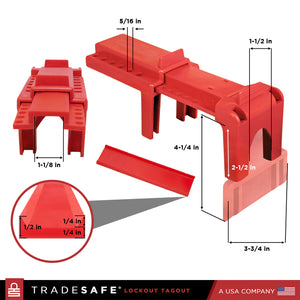

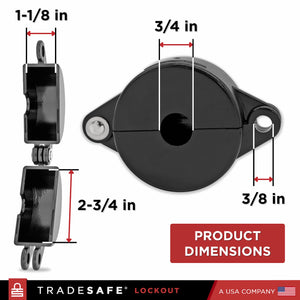

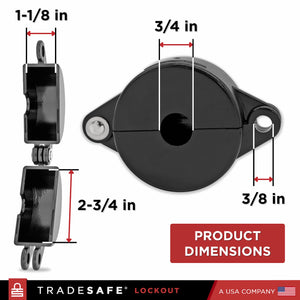

Standard Ball Valve Lockout – 1/4” to 1” Pipe Diameter

Regular price $26.95Regular price$56.00-52%Sale price $26.95 -

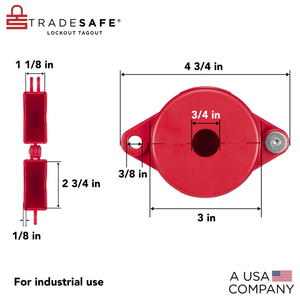

Standard Ball Valve Lockout – 1-1/4” to 2-1/2” Pipe Diameter

Regular price $23.95Regular price$23.00Sale price $23.95 -

-56%

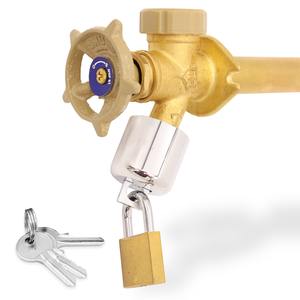

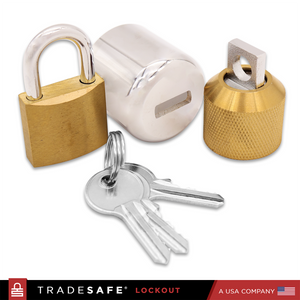

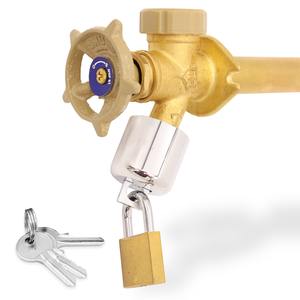

Outdoor Faucet Lock with Safety Padlock - 2 Keys

Regular price $21.95Regular price$50.00-56%Sale price $21.95 -

-58%

Water Spigot Lock with Padlock - 3 Keys

Regular price $20.95Regular price$50.00-58%Sale price $20.95 -

-20%

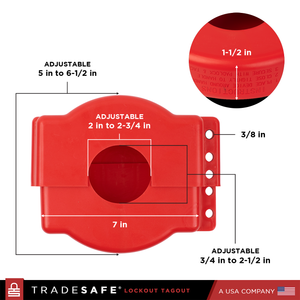

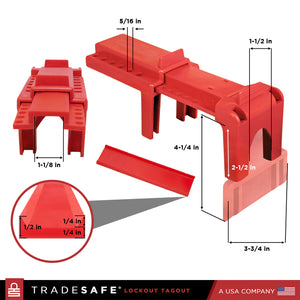

Adjustable Ball Valve Lockout - 1/2" to 4-1/4" Pipe Diameter

Regular price $39.95Regular price$50.00-20%Sale price $39.95 -

-52%

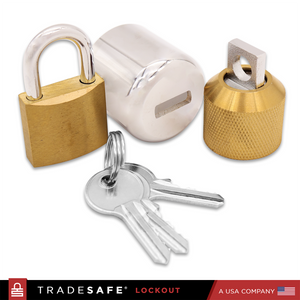

Metal Outdoor Faucet Lock

Regular price $23.99Regular price$50.00-52%Sale price $23.99

TRADESAFE provides lockout tagout valve locks that are durable, reliable, and precision-engineered to meet OSHA standard 1919.147. These valve lockout devices are made of corrosion-resistant materials and are tamper-proof, so the valve does not open until it is safe to do so.

They are also designed to fit a variety of valves, including gate valves, ball valves, and butterfly valves, conveniently and securely. Plus, these valve lockouts can easily fit over valve handles with diameters that range from ¼” to 24”.

Controlling hazardous energy is a serious matter, but that doesn’t mean that safety measures should be complicated. These valve lockout devices are designed for simple installation while ensuring worker safety for as long as necessary.