-

-34%

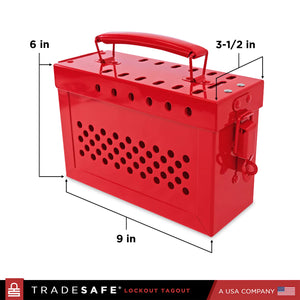

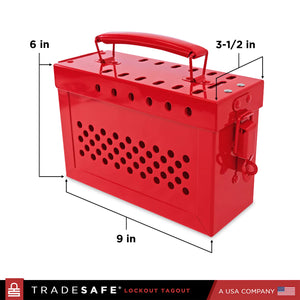

Portable Group Lockout Box

Regular price $39.50Regular price$60.00-34%Sale price $39.50

Adding an extra layer of security can’t hurt, especially when it comes to industrial facilities that have certain safety hazards. This is something that TRADESAFE group lockout boxes can offer.

These lockout boxes come with multiple lock points that can each accommodate one personal padlock per authorized employee. Employees can remove their personal locks once they are done working. Even if just one padlock remains attached, the box will not open, and the machine’s keys will remain inside. Thus, the machine cannot be powered on until the very last employee is done working on it.

This is another effective way of ensuring the safety of employees and that any valves, switches, or breakers remain locked until the machine is safe to operate again.