-

-53%

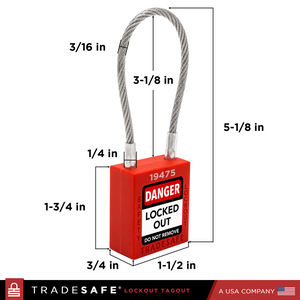

Keyed Different Cable Padlocks - 10 Red Locks - 2 Keys Per Lock

Regular price $74.95Regular price$159.00-53%Sale price $74.95 -

-53%

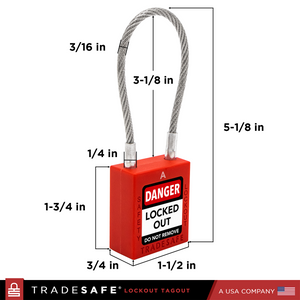

Keyed Alike Unlimited Cable Padlocks - 10 Red Locks - 2 Keys Per Lock

Regular price $74.95Regular price$159.00-53%Sale price $74.95 -

-50%

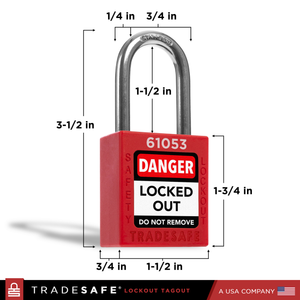

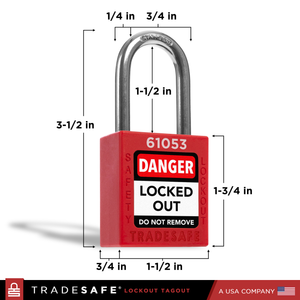

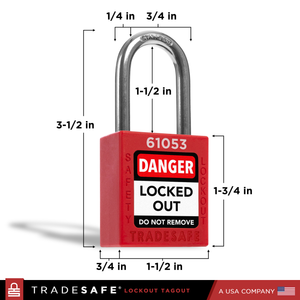

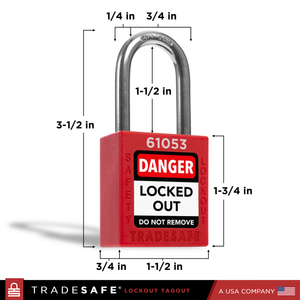

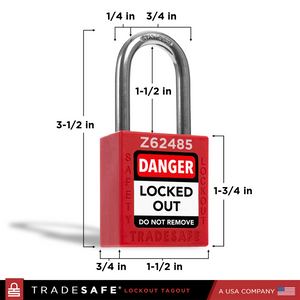

Keyed Different Lockout Locks - 7 Red Padlocks - 1 Key Per Lock

Regular price $45.95Regular price$91.00-50%Sale price $45.95 -

-50%

Keyed Different Lockout Locks - 7 Red Padlocks - 2 Keys Per Lock

Regular price $45.95Regular price$91.00-50%Sale price $45.95 -

-50%

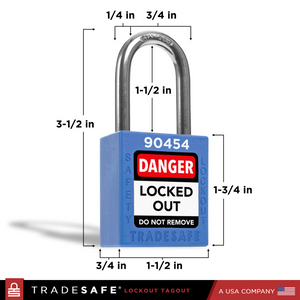

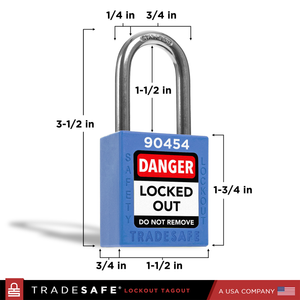

Keyed Different Lockout Locks - 7 Blue Padlocks - 2 Keys Per Lock

Regular price $45.95Regular price$91.00-50%Sale price $45.95 -

-50%

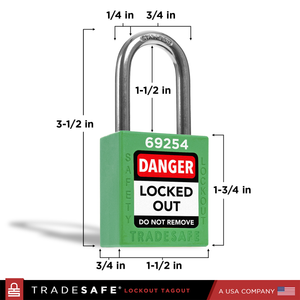

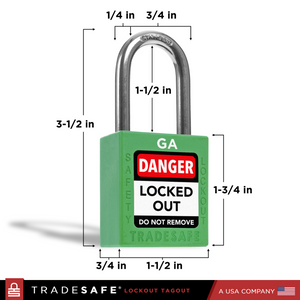

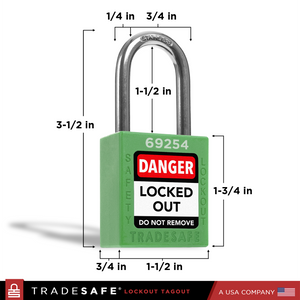

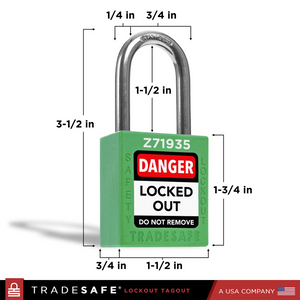

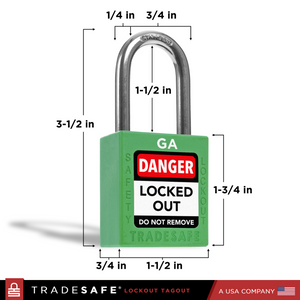

Keyed Different Lockout Locks - 7 Green Padlocks - 2 Keys Per Lock

Regular price $45.95Regular price$91.00-50%Sale price $45.95 -

-50%

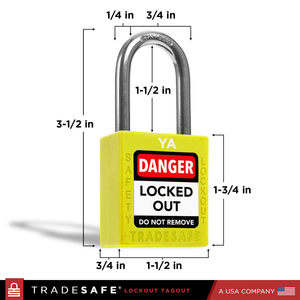

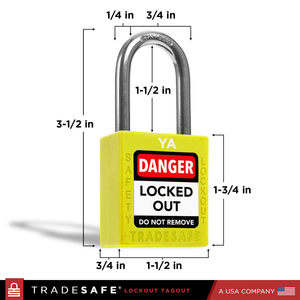

Keyed Different Lockout Locks - 7 Yellow Padlocks - 2 Keys Per Lock

Regular price $45.95Regular price$91.00-50%Sale price $45.95 -

-50%

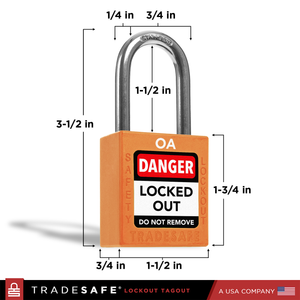

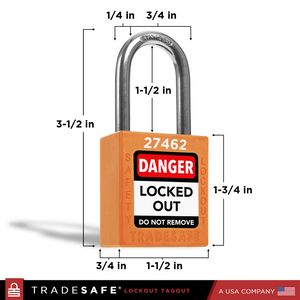

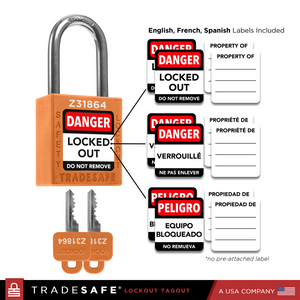

Keyed Different Lockout Locks - 7 Orange Padlocks - 2 Keys Per Lock

Regular price $45.95Regular price$91.00-50%Sale price $45.95 -

-50%

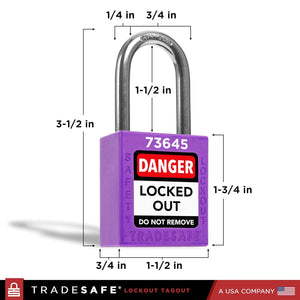

Keyed Different Lockout Locks - 7 Purple Padlocks - 2 Keys Per Lock

Regular price $45.95Regular price$91.00-50%Sale price $45.95 -

-62%

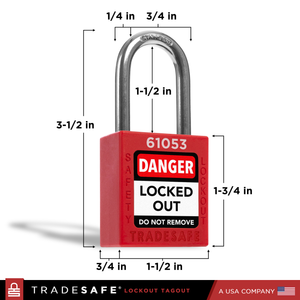

Keyed Different Lockout Locks - 10 Red Padlocks - 1 Key Per Lock

Regular price $59.95Regular price$159.00-62%Sale price $59.95 -

-62%

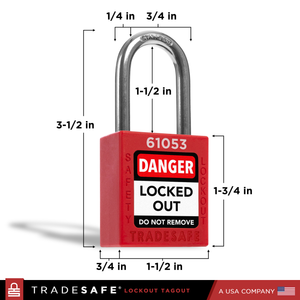

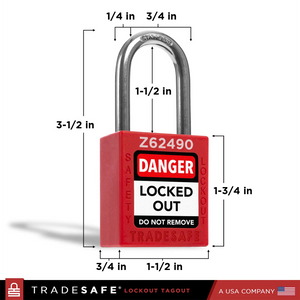

Keyed Different Lockout Locks - 10 Red Padlocks - 2 Keys Per Lock

Regular price $59.95Regular price$159.00-62%Sale price $59.95 -

-62%

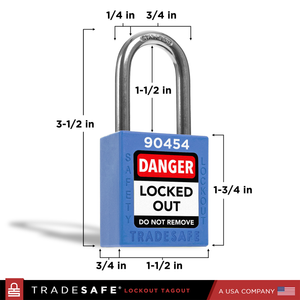

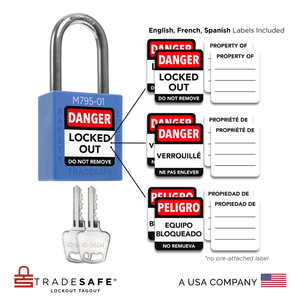

Keyed Different Lockout Locks - 10 Blue Padlocks - 2 Keys Per Lock

Regular price $59.95Regular price$159.00-62%Sale price $59.95 -

-62%

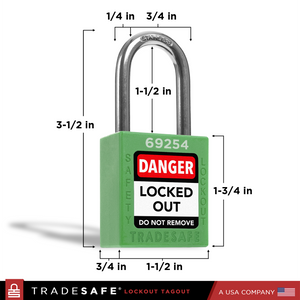

Keyed Different Lockout Locks - 10 Green Padlocks - 2 Keys Per Lock

Regular price $59.95Regular price$159.00-62%Sale price $59.95 -

-62%

Keyed Different Lockout Locks - 10 Yellow Padlocks - 2 Keys Per Lock

Regular price $59.95Regular price$159.00-62%Sale price $59.95 -

-62%

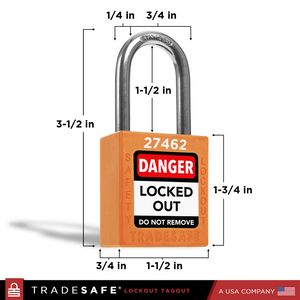

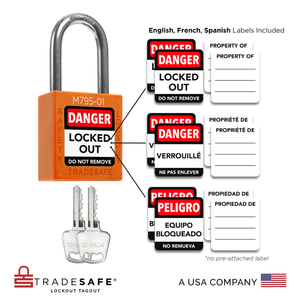

Keyed Different Lockout Locks - 10 Orange Padlocks - 2 Keys Per Lock

Regular price $59.95Regular price$159.00-62%Sale price $59.95 -

-62%

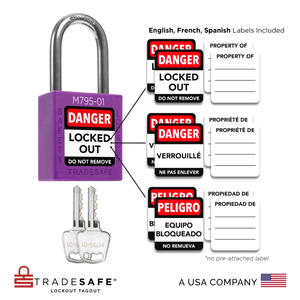

Keyed Different Lockout Locks - 10 Purple Padlocks - 2 Keys Per Lock

Regular price $59.95Regular price$159.00-62%Sale price $59.95 -

-62%

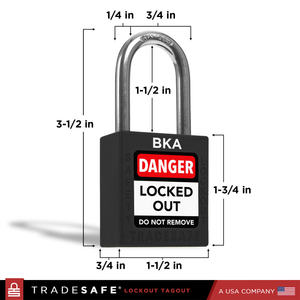

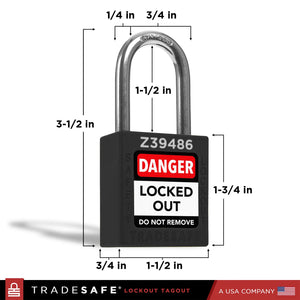

Keyed Different Lockout Locks - 10 Black Padlocks - 2 Keys Per Lock

Regular price $59.95Regular price$159.00-62%Sale price $59.95 -

-62%

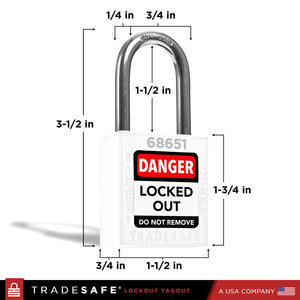

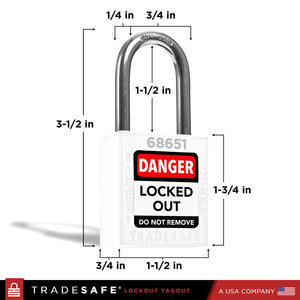

Keyed Different Lockout Locks - 10 White Padlocks - 2 Keys Per Lock

Regular price $59.95Regular price$159.00-62%Sale price $59.95 -

-50%

Keyed Alike Lockout Locks - 7 Red Padlocks - 2 Keys Per Lock

Regular price $45.95Regular price$91.00-50%Sale price $45.95 -

-62%

Keyed Alike Lockout Locks - 10 Red Padlocks - 2 Keys Per Lock

Regular price $59.95Regular price$159.00-62%Sale price $59.95 -

-62%

Keyed Alike Lockout Locks - 10 Blue Padlocks - 2 Keys Per Lock

Regular price $59.95Regular price$159.00-62%Sale price $59.95 -

-62%

Keyed Alike Lockout Locks - 10 Green Padlocks - 2 Keys Per Lock

Regular price $59.95Regular price$159.00-62%Sale price $59.95 -

-62%

Keyed Alike Lockout Locks - 10 Yellow Padlocks - 2 Keys Per Lock

Regular price $59.95Regular price$159.00-62%Sale price $59.95 -

-62%

Keyed Alike Lockout Locks - 10 Purple Padlocks - 2 Keys Per Lock

Regular price $59.95Regular price$159.00-62%Sale price $59.95 -

-62%

Keyed Alike Lockout Locks - 10 Orange Padlocks - 2 Keys Per Lock

Regular price $59.95Regular price$159.00-62%Sale price $59.95 -

-62%

Keyed Alike Lockout Locks - 10 Black Padlocks - 2 Keys Per Lock

Regular price $59.95Regular price$159.00-62%Sale price $59.95 -

-62%

Keyed Alike Lockout Locks - 10 White Padlocks - 2 Keys Per Lock

Regular price $59.95Regular price$159.00-62%Sale price $59.95 -

-61%

Keyed Alike Lockout Locks - 20 Red Padlocks - 2 Keys Per Lock

Regular price $119.95Regular price$309.00-61%Sale price $119.95 -

-50%

Keyed Alike Unlimited Lockout Locks - 7 Red Padlocks - 2 Keys Per Lock

Regular price $45.95Regular price$91.00-50%Sale price $45.95 -

-62%

Keyed Alike Unlimited Lockout Locks - 10 Red Padlocks - 2 Keys Per Lock

Regular price $59.95Regular price$159.00-62%Sale price $59.95 -

-62%

Keyed Alike Unlimited Lockout Locks - 10 Blue Padlocks - 2 Keys Per Lock

Regular price $59.95Regular price$159.00-62%Sale price $59.95 -

-62%

Keyed Alike Unlimited Lockout Locks - 10 Green Padlocks - 2 Keys Per Lock

Regular price $59.95Regular price$159.00-62%Sale price $59.95 -

-62%

Keyed Alike Unlimited Lockout Locks - 10 Yellow Padlocks - 2 Keys Per Lock

Regular price $59.95Regular price$159.00-62%Sale price $59.95 -

-62%

Keyed Alike Unlimited Lockout Locks - 10 Orange Padlocks - 2 Keys Per Lock

Regular price $59.95Regular price$159.00-62%Sale price $59.95 -

-62%

Keyed Alike Unlimited Lockout Locks - 10 Purple Padlocks - 2 Keys Per Lock

Regular price $59.95Regular price$159.00-62%Sale price $59.95 -

-64%

Keyed Alike Unlimited Lockout Locks - 10 Black Padlocks - 2 Keys Per Lock

Regular price $59.95Regular price$165.00-64%Sale price $59.95 -

-64%

Keyed Alike Unlimited Lockout Locks - 10 White Padlocks - 2 Keys Per Lock

Regular price $59.95Regular price$165.00-64%Sale price $59.95 -

-51%

Keyed Different Lockout Locks with Master Keys - 10 Red Padlocks - 2 Keys Per Lock

Regular price $77.95Regular price$159.00-51%Sale price $77.95 -

-51%

Keyed Different Lockout Locks with Master Keys - 10 Blue Padlocks - 2 Keys Per Lock

Regular price $77.95Regular price$159.00-51%Sale price $77.95 -

-51%

Keyed Different Lockout Locks with Master Keys - 10 Green Padlocks - 2 Keys Per Lock

Regular price $77.95Regular price$159.00-51%Sale price $77.95 -

-51%

Keyed Different Lockout Locks with Master Keys - 10 Yellow Padlocks - 2 Keys Per Lock

Regular price $77.95Regular price$159.00-51%Sale price $77.95 -

-51%

Keyed Different Lockout Locks with Master Keys - 10 Purple Padlocks - 2 Keys Per Lock

Regular price $77.95Regular price$159.00-51%Sale price $77.95 -

-51%

Keyed Different Lockout Locks with Master Keys - 10 Orange Padlocks - 2 Keys Per Lock

Regular price $77.95Regular price$159.00-51%Sale price $77.95 -

-51%

Keyed Different Lockout Locks with Master Keys - 10 Black Padlocks - 2 Keys Per Lock

Regular price $77.95Regular price$159.00-51%Sale price $77.95 -

-51%

Keyed Different Lockout Locks with Master Keys - 10 White Padlocks - 2 Keys Per Lock

Regular price $77.95Regular price$159.00-51%Sale price $77.95 -

-52%

Keyed Alike Aluminum Padlock - 10 Red Padlocks - 2 Keys Per Lock

Regular price $94.95Regular price$199.00-52%Sale price $94.95 -

-52%

Keyed Alike Aluminum Padlock - 10 Blue Padlocks - 2 Keys Per Lock

Regular price $94.95Regular price$199.00-52%Sale price $94.95 -

-52%

Keyed Alike Aluminum Padlock - 10 Green Padlocks - 2 Keys Per Lock

Regular price $94.95Regular price$199.00-52%Sale price $94.95

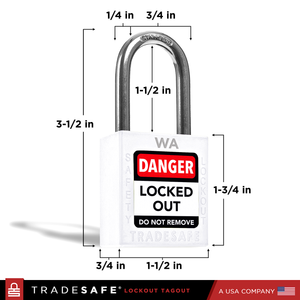

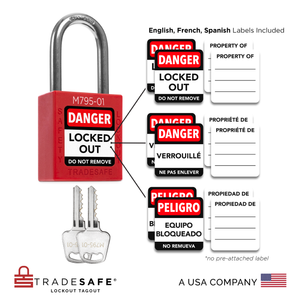

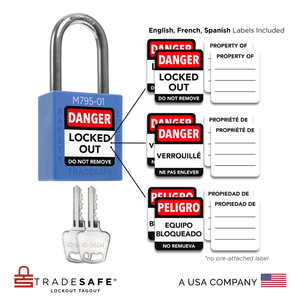

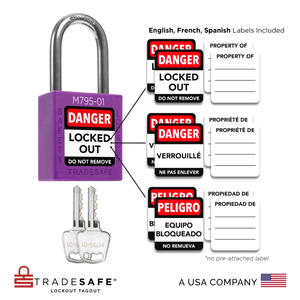

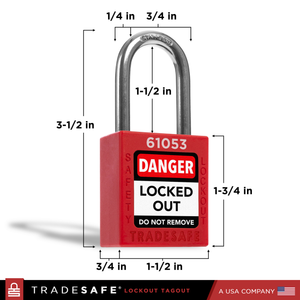

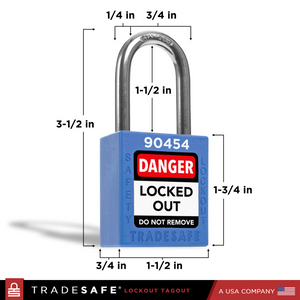

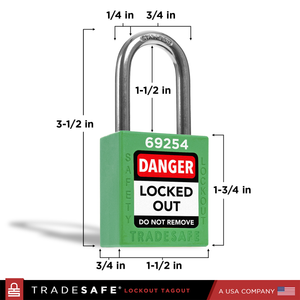

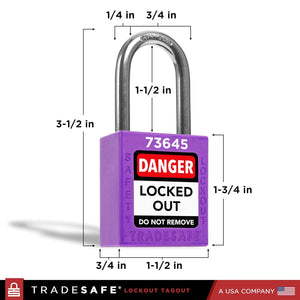

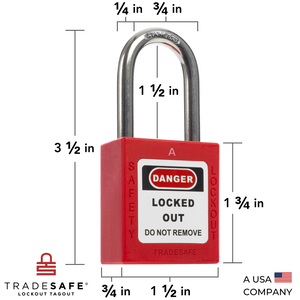

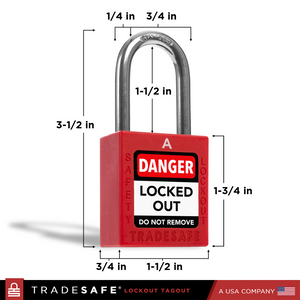

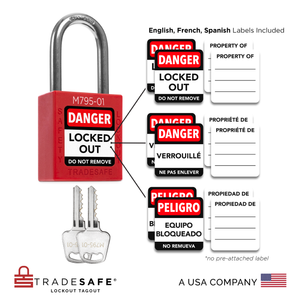

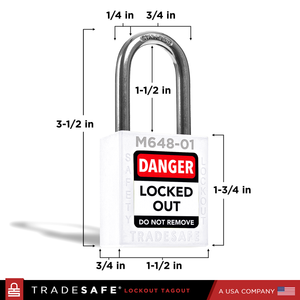

TRADESAFE’s premium lockout padlocks are guaranteed to be durable, corrosion-resistant, and – most importantly – compliant with OSHA 1910.147 standard. These aren’t your ordinary hardware store padlocks. They are specially designed for lockout tagout applications and are made to withstand the demands of industrial facilities.

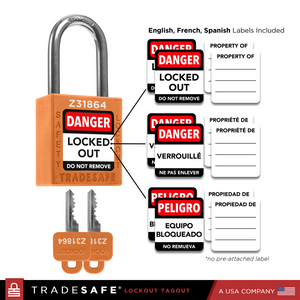

We offer both keyed alike and keyed different locks. Our locks also come with one key or two keys for each. All keys are engraved with a set of numbers that match the numbers on their corresponding lock. The locks also have a key-retaining feature, which means that they won’t release their keys until they’re securely locked. This helps provide an extra level of security and safety.

These padlocks are highly versatile and can be used in a variety of ways. Because of their hardwearing construction, they can withstand heavy and regular use. These lockout locks are included the lockout tagout kit and are usually used with appropriate lockout tags.