-

-62%

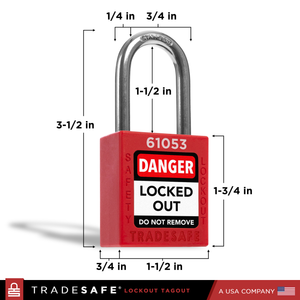

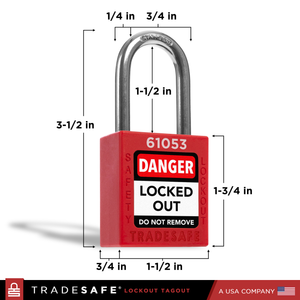

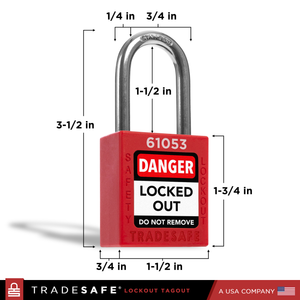

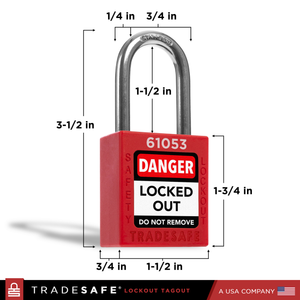

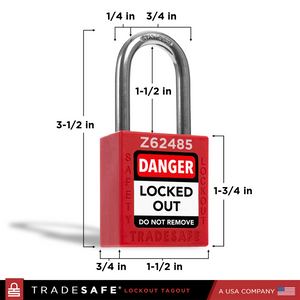

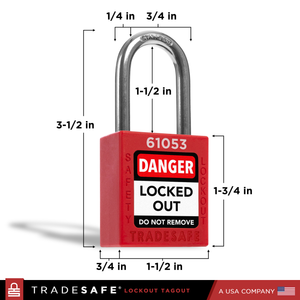

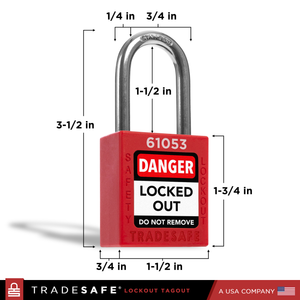

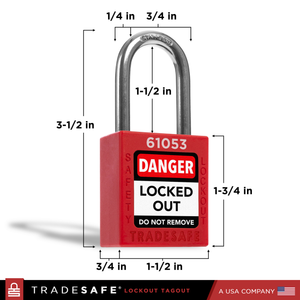

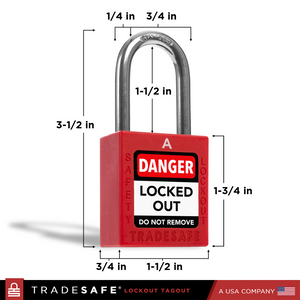

Keyed Different Lockout Locks - 10 Red Padlocks - 2 Keys Per Lock

Regular price $59.95Regular price$159.00-62%Sale price $59.95 -

-62%

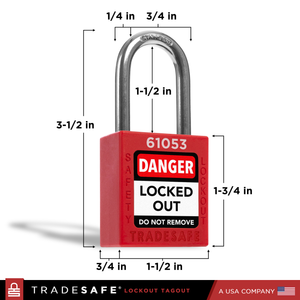

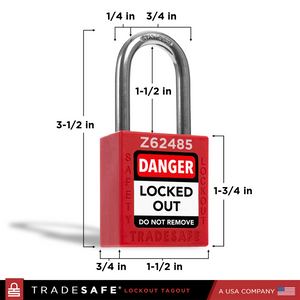

Keyed Different Lockout Locks - 10 Red Padlocks - 1 Key Per Lock

Regular price $59.95Regular price$159.00-62%Sale price $59.95 -

-34%

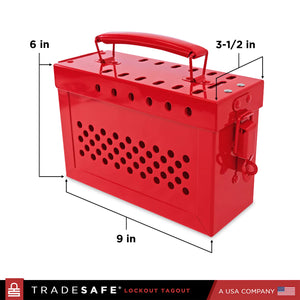

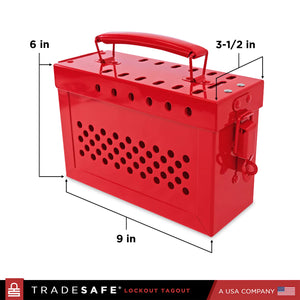

Portable Group Lockout Box

Regular price $39.50Regular price$60.00-34%Sale price $39.50 -

-38%

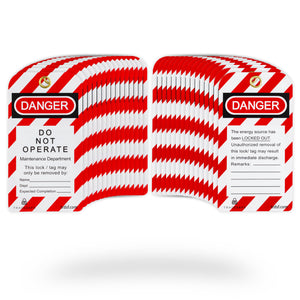

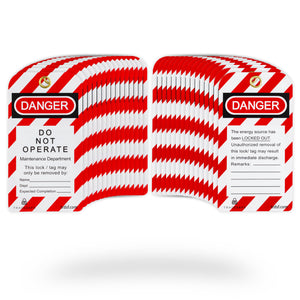

Lockout Tagout Danger Tags – Pack of 30

Regular price $36.95Regular price$60.00-38%Sale price $36.95 -

-42%

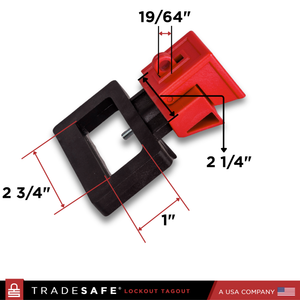

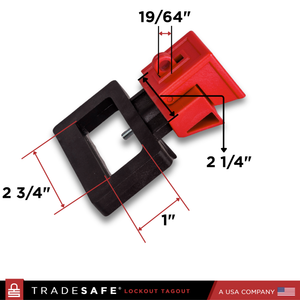

Clamp-on Circuit Breaker Lockout Device – 120/277 Volt – 10 Pack

Regular price $69.95Regular price$120.00-42%Sale price $69.95 -

-50%

Adjustable Cable Lock Out Device - 6ft

Regular price $17.98Regular price$36.00-50%Sale price $17.98 -

-47%

Lockout Tagout Hasp – Nylon and Steel, 1" Jaw Diameter, 6 Pack

Regular price $35.95Regular price$68.00-47%Sale price $35.95 -

-53%

Clamp-on Circuit Breaker Lockout Device – 480/600 Volt – 3 Pack

Regular price $27.95Regular price$60.00-53%Sale price $27.95 -

-54%

Electrical Lockout Tagout Kit – 2 Keys Per Lock

Regular price $68.95Regular price$149.00-54%Sale price $68.95 -

-38%

Bilingual Lockout Tagout Danger Tags – Pack of 30

Regular price $36.95Regular price$60.00-38%Sale price $36.95 -

-62%

Personal Lockout Tagout Kit – 2 Keys Per Lock

Regular price $41.95Regular price$110.00-62%Sale price $41.95 -

-40%

Lockout Tagout Station - XL

Regular price $199.99Regular price$335.00-40%Sale price $199.99 -

-62%

Complete Breaker Lockout Tagout Kit – 1 Key Per Lock

Regular price $79.90Regular price$209.00-62%Sale price $79.90 -

-62%

Complete Breaker Lockout Tagout Kit – 2 Keys Per Lock

Regular price $79.90Regular price$209.00-62%Sale price $79.90 -

-49%

Push Button Lockout - Box Type - Large

Regular price $39.95Regular price$79.00-49%Sale price $39.95 -

-50%

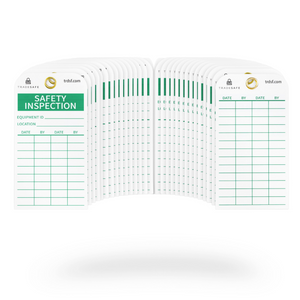

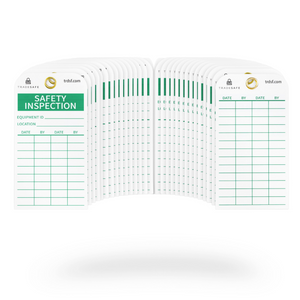

Safety Inspection Tags – Pack of 30

Regular price $29.95Regular price$60.00-50%Sale price $29.95 -

-50%

Clamp-on Circuit Breaker Lockout Device – Oversized 480/600 Volt – 3 Pack

Regular price $34.95Regular price$70.00-50%Sale price $34.95 -

-50%

Keyed Different Lockout Locks - 7 Red Padlocks - 2 Keys Per Lock

Regular price $45.95Regular price$91.00-50%Sale price $45.95 -

-36%

Lockout Tagout Cabinet - LOTO Devices Not Included - Large

Regular price $189.95Regular price$299.00-36%Sale price $189.95 -

-50%

Keyed Different Lockout Locks - 7 Red Padlocks - 1 Key Per Lock

Regular price $45.95Regular price$91.00-50%Sale price $45.95 -

-62%

Personal Lockout Tagout Kit – 1 Key Per Lock

Regular price $41.95Regular price$110.00-62%Sale price $41.95 -

-56%

Professional Lockout Tagout Kit – 2 Keys Per Lock

Regular price $84.95Regular price$193.00-56%Sale price $84.95 -

-62%

Keyed Alike Lockout Locks - 10 Red Padlocks - 2 Keys Per Lock

Regular price $59.95Regular price$159.00-62%Sale price $59.95 -

-54%

Electrical Lockout Tagout Kit – 1 Key Per Lock

Regular price $68.95Regular price$149.00-54%Sale price $68.95 -

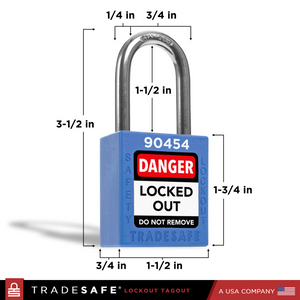

-62%

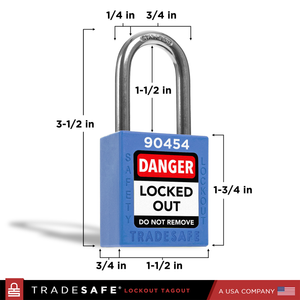

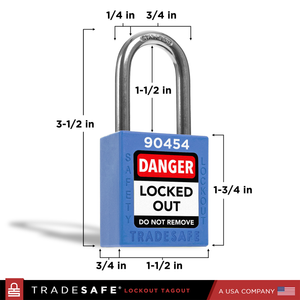

Keyed Different Lockout Locks - 10 Blue Padlocks - 2 Keys Per Lock

Regular price $59.95Regular price$159.00-62%Sale price $59.95 -

-49%

Lockout Tagout Station – Medium

Regular price $109.95Regular price$215.00-49%Sale price $109.95 -

-62%

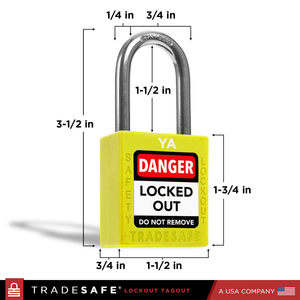

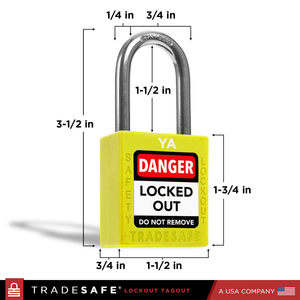

Keyed Different Lockout Locks - 10 Yellow Padlocks - 2 Keys Per Lock

Regular price $59.95Regular price$159.00-62%Sale price $59.95 -

-42%

Lockout Tagout Hasp – Nylon and Steel, 1-1/2" Jaw Diameter, 6 Pack

Regular price $45.95Regular price$79.00-42%Sale price $45.95 -

-37%

Plug Lockout Device - 220V - Large

Regular price $18.95Regular price$29.95-37%Sale price $18.95 -

-62%

Keyed Alike Unlimited Lockout Locks - 10 Yellow Padlocks - 2 Keys Per Lock

Regular price $59.95Regular price$159.00-62%Sale price $59.95 -

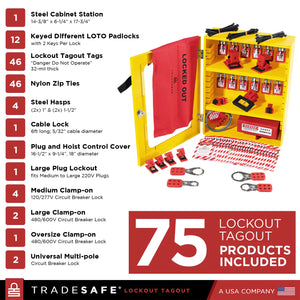

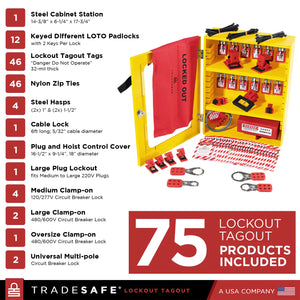

-16%

Lockout Tagout Cabinet - 75 Devices

Regular price $420.95Regular price$499.00-16%Sale price $420.95 -

-62%

Keyed Alike Lockout Locks - 10 Blue Padlocks - 2 Keys Per Lock

Regular price $59.95Regular price$159.00-62%Sale price $59.95 -

-56%

Professional Lockout Tagout Kit – 1 Key Per Lock

Regular price $84.95Regular price$193.00-56%Sale price $84.95 -

-44%

Plug Lockout Device - 110 to 125V - Medium

Regular price $13.95Regular price$24.95-44%Sale price $13.95 -

-45%

Lockout Tagout Danger Tags – Pack of 60

Regular price $65.95Regular price$120.00-45%Sale price $65.95 -

-62%

Keyed Alike Unlimited Lockout Locks - 10 Red Padlocks - 2 Keys Per Lock

Regular price $59.95Regular price$159.00-62%Sale price $59.95 -

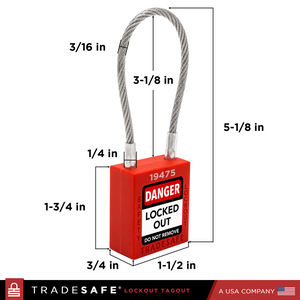

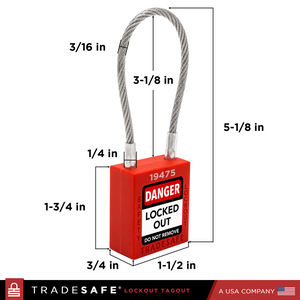

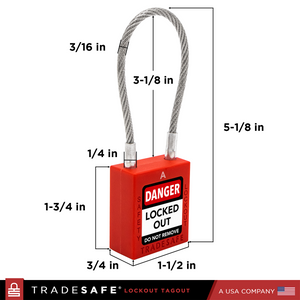

-53%

Keyed Different Cable Padlocks - 10 Red Locks - 2 Keys Per Lock

Regular price $74.95Regular price$159.00-53%Sale price $74.95 -

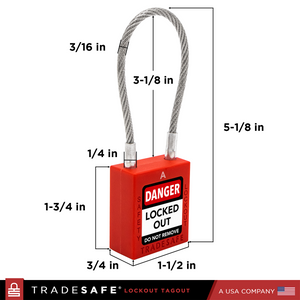

-53%

Keyed Alike Unlimited Cable Padlocks - 10 Red Locks - 2 Keys Per Lock

Regular price $74.95Regular price$159.00-53%Sale price $74.95 -

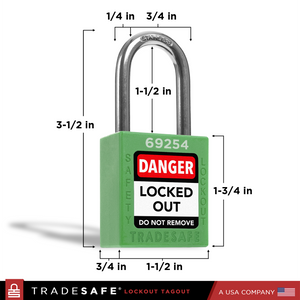

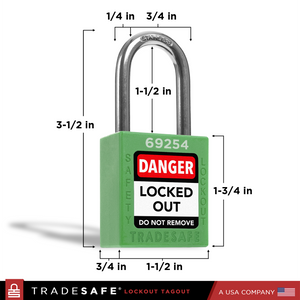

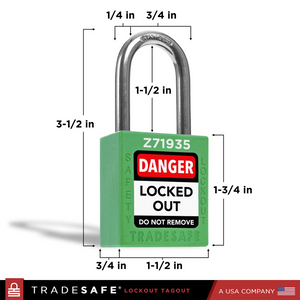

-62%

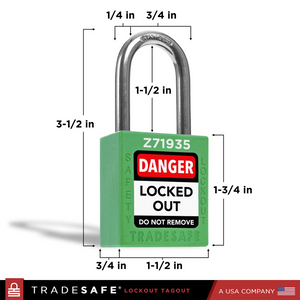

Keyed Different Lockout Locks - 10 Green Padlocks - 2 Keys Per Lock

Regular price $59.95Regular price$159.00-62%Sale price $59.95 -

-47%

Lockout Tagout Bag, 9-3/8" x 5-1/2" x 4-5/16”

Regular price $15.99Regular price$30.00-47%Sale price $15.99 -

-49%

Push Button Lockout - Box Type - XL

Regular price $44.95Regular price$89.00-49%Sale price $44.95 -

-61%

Lockout Tagout Hasp with 6 Padlock Holes – Polypropylene – 3 Pack

Regular price $14.95Regular price$38.00-61%Sale price $14.95 -

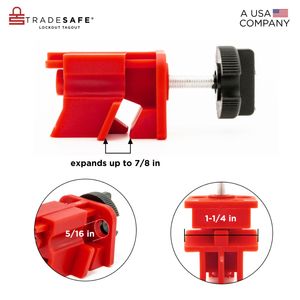

Sold out

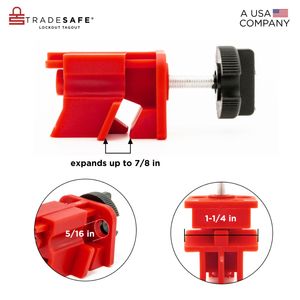

Universal Circuit Breaker Lockout Device - up to 7/8" Tie Bar – 10 Pack

Regular price $78.95Regular price$130.00-39%Sale price $78.95 -

-62%

Keyed Alike Lockout Locks - 10 Yellow Padlocks - 2 Keys Per Lock

Regular price $59.95Regular price$159.00-62%Sale price $59.95 -

-50%

Keyed Different Lockout Locks - 7 Blue Padlocks - 2 Keys Per Lock

Regular price $45.95Regular price$91.00-50%Sale price $45.95 -

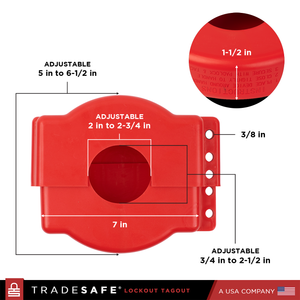

-17%

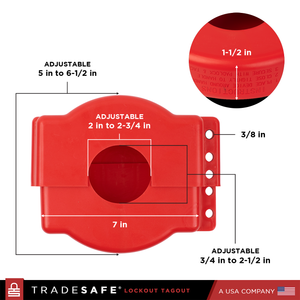

Adjustable Gate Valve Lockout - 1” to 6-1/2” Handle Diameter

Regular price $19.95Regular price$24.00-17%Sale price $19.95 -

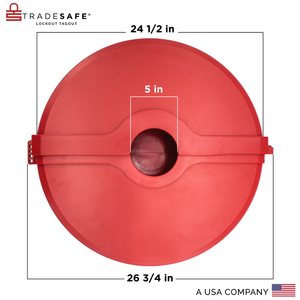

-33%

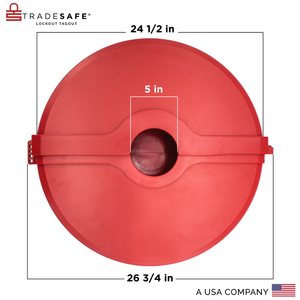

Gate Valve Lockout – 18” to 24” Valve Handle Diameter

Regular price $139.95Regular price$209.00-33%Sale price $139.95 -

-62%

Keyed Alike Lockout Locks - 10 Green Padlocks - 2 Keys Per Lock

Regular price $59.95Regular price$159.00-62%Sale price $59.95

Lockout tagout devices are used in lockout/tagout procedures to disconnect machines and equipment from electric, hydraulic, pneumatic, or other forms of power sources. This protects personnel during maintenance or servicing operations, ensuring that workers are protected from safety hazards in the workplace.

TRADESAFE’s LOTO devices create a physical barrier so that unauthorized employees will not be able to accidentally switch on a machine while it is being serviced. Each of our devices is made of durable material of the best quality we can find, ensuring that your employees are well-protected and safe.

We don’t cut corners and we don’t think twice about spending more on premium materials to provide you with premium products. TRADESAFE LOTO devices are all compliant with OSHA Standard 1910.147, or the Control of Hazardous Energy.