An extension cord is a length of flexible electrical power cable with a plug on one end and one or more sockets on the other end. It's primarily designed to extend an electrical power source to devices that are situated away from the main power outlet. In the industrial and manufacturing sectors, the extension cord functions as the lifeline for heavy machinery, lighting systems, and countless tools. These sectors demand the highest quality, as a single malfunction could lead to significant downtime, financial losses, or worse, jeopardizing safety. Recognizing the importance of this tool, we bring you this comprehensive review of the best heavy duty extension cord in the industry.

Different Types of Extension Cord

- General Use Extension Cords: These cords are versatile and primarily designed for indoor environments, suitable for powering everyday appliances and lamps, and ensuring consistent electricity flow without overpowering.

- Heavy Duty Extension Cords: Engineered for high demand, these cords boast a thicker gauge, allowing them to supply power to larger appliances and heavy-duty machinery without overheating or breaking down.

- Outdoor Extension Cords: Crafted to withstand various elements, and outdoor extension cord heavy duty is built with a robust exterior, offering protection against moisture, direct sunlight, and fluctuating temperatures.

- Industrial Extension Cords: The pinnacle of durability, an industrial extension cord is tailored for the harshest industrial settings, providing added safeguards against chemical exposures, abrasive surfaces, and extreme temperatures.

Designation Lettering Meaning

Each extension cord often comes with a series of letters on its insulation or jackets. These letters offer more information on the cord's design and usage specifications based on the type of wire inside it. Here's a guide to make sense of them:

- S: Represents flexibility; crafted for general use.

- W: Tailored for the outdoors, this cord braves external elements.

- J: Equipped with a standard 300-volt insulation. Absence of 'J' typically implies a robust 600-volt insulation for more rigorous usage.

- P: Features parallel wire construction; typically seen in air conditioner cords and standard household extensions.

- T: The cord jacket is sculpted from vinyl thermoplastic.

- E: Jacket is derived from thermoplastic elastomer rubber (TPE).

- O: Offers resistance against oils.

- FT2: Flame retardancy is its forte, adding an extra layer of safety.

- CL2S: Specifically engineered for in-wall constructions.

- SRDT: A robust wire, perfect for high amperage products given its heavy-duty nature.

- HPN: Primed for high-temperature scenarios, particularly with appliances.

Best Heavy Duty Extension Cord

BAD ASS Heavy-Duty Dual Lighted Extension Cord with Safety CGM

The BAD ASS Heavy-Duty Dual Lighted Extension Cord is a testament to engineering excellence with its large gauge wiring, tailored specifically for high-power tools over vast distances, and dual lighted ends that not only offer clear visibility of power status but also guarantee grounding assurance. Coupled with a reinforced, molded strain relief, it promises unmatched durability to withstand occasional accidental impact.

Pros:

- Large gauge design perfect for high-power tools.

- Dual lighted ends for clear power and safety status indication.

Cons:

- Premium price might deter budget-conscious buyers.

- Single outlet may restrict multitasking tool use.

VANGUARD50 ft. x 10/3 Gauge Triple Tap Extension Cord

Vanguard's Triple Tap Extension Cord, a 50-foot marvel, combines the convenience of powering three devices from one source, ensuring optimal space and resource utilization, with a robust terrain-resistant jacket that showcases its preparedness for both indoor and outdoor challenges, regardless of environmental conditions.

Pros:

- Multi-outlet design for increased versatility.

- Durable terrain-resistant jacket adaptable to diverse settings.

Cons:

- The 10/3 gauge might not suit the highest power-intensive tools.

- Limited certifications may not cater to broader industry standards.

Clear Power 50 ft 12/3 SJTW Outdoor Extension Cord Heavy Duty

Clear Power sets new industry benchmarks with this 50-foot cord, highlighting a meticulously engineered 12-gauge wiring system built to power even the most demanding appliances up to 15 amps, ensuring operational continuity and efficiency. Further setting it apart is an LED power light, offering an immediate and clear view of the power status, while its design remains resilient, ensuring full operability even in the harshest temperature extremes.

Pros:

- 12-gauge design suitable for high-demand tools and appliances.

- LED indicator ensures clear visibility of power status.

Cons:

- Single outlet design might limit device connectivity.

- The specific lack of oil-resistance may pose challenges in certain environments.

Iron Forge 50 Ft Outdoor Heavy Duty Extension Cord with 3 Electrical Outlets

The Iron Forge 50-foot extension cord boasts strength and adaptability, its 10-gauge construction effortlessly channeling current to power even the most demanding high-wattage devices and tools. Its prowess is further highlighted by its reinforced prongs, ensuring durability while the LED power light guarantees continuous power visibility, even in challenging environments.

Pros:

- 10-gauge wiring designed for heavy-duty electrical needs.

- Multiple outlets enhance adaptability and usage convenience.

Cons:

- May be bulkier due to its heavy-duty design.

- The price point might be on the higher side for budget-oriented users.

Voltec Pro Outdoor Extension Cord (50 Feet, 12 Gauge, 15 A)

Voltec Pro's Outdoor Industrial Extension Cord offers practicality with raw power, the 50-foot length ensuring extended reach while its robust 15 A capacity guarantees uninterrupted current flow to even the most power-intensive machinery. This cord's heft, ensconced within a sturdy yellow and blue jacket, is a testament to its enduring durability, even though it might initially seem challenging to maneuver fresh out of the packaging.

Pros:

- High power capacity suitable for industrial machinery.

- Durable and dependable jacket design.

Cons:

- Initial handling might be slightly cumbersome due to its weight.

- Lacks multiple outlet options.

US Wire & Cable 14/3 SJTW Outdoor Lighted Extension Cord, 100-Feet

US Wire & Cable has crafted an industrial extension cord that's both formidable in length and impeccable in performance, with the 100-foot design ensuring extensive reach, and its resilient construction promising reliability even in intensive electrical jobs. Its compact design comes with a powerhouse ready to deliver unparalleled value, especially for those seeking both length and affordability.

Pros:

- Extended length ideal for large workspaces.

- Surprisingly compact design for a 100-foot cord.

Cons:

- 14-gauge design might not be suited for extremely high-powered tools.

- The single outlet may pose limitations for multitasking.

Southwire Polar Solar 1638SW0061

Southwire's Outdoor Extension Cord Heavy Duty is more than just a conduit for power; it's an engineering marvel designed for larger power transfers, far outstripping common 16-gauge cords, and its inherent resistance to chemicals and oil makes it an industrial favorite. The cord is also designed to effortlessly handle extreme cold conditions, complemented by its lighted connections, ensuring both flexibility and visibility in demanding tasks.

Pros:

- Enhanced power transfer capacity.

- Resistant to chemicals, oil, and extreme temperatures.

Cons:

- The specific design might be overkill for light-duty tasks.

- Potentially higher cost than basic extension cords.

Yellow Jacket 2737 12/3 Locking Extension Cord

The Yellow Jacket 12/3 locking extension cord with its distinctive yellow PVC jacket not only enhances visibility but also mitigates the risk of tripping, ensuring work-site safety. Its SJTW designation speaks volumes about its readiness for hard use, and the unique locking plugs are designed to keep tools firmly plugged in, maximizing productive time and minimizing unnecessary adjustments.

Pros:

- High-visibility jacket reduces tripping hazards.

- Locking plugs ensure consistent power delivery without unplugging.

Cons:

- Length may not be suitable for all industrial needs.

Things to Consider Before Buying an Extension Cord

Cord Length

When considering an extension cord, one of the primary factors is its length. Too short, and it won’t serve its purpose; too long, and it could become a potential trip hazard or decrease the efficiency due to voltage drop. For choosing an industrial extension cord, ensure that you’re choosing a length that caters to the distance between the power source and the device or tool, allowing for some flexibility.

Amperage and Wattage

Understanding the electrical capacity of the extension cord is critical. Selecting a cord with inadequate amperage can result in overheating, potentially causing fire hazards. Thus, it's essential to match or exceed the total amperage of all devices that will be plugged into the cord, ensuring safe and efficient operation.

Cord Gauge

The thickness of the wire, commonly known as the gauge, directly correlates with the cord's capacity to carry current. A lower gauge number indicates a thicker wire, suitable for more demanding electrical needs, especially prevalent in industrial settings. Always opt for an extension cord that can safely handle the power requirements of your tools or machinery.

Insulation and Jacket Material

The insulation and jacket material determine the cord’s durability, flexibility, and resistance to environmental factors. In the industrial context, it’s crucial to select cords that are resistant to oils, chemicals, and temperature extremes. A cord's jacket material can signify its applicability, whether indoor, outdoor, or both.

Safety Certifications and Ratings

Safety is a priority, especially in an industrial setting. Always look for extension cords that have been certified by recognized organizations, such as UL (Underwriters Laboratories) or ETL (Intertek). These certifications provide assurance that the cord has undergone rigorous testing and meets specific safety standards.

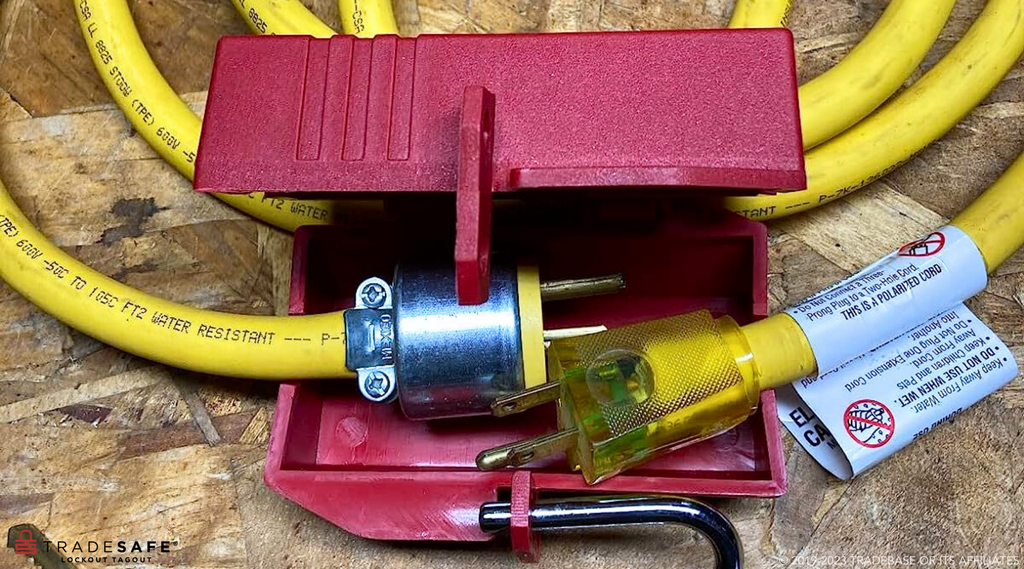

What is the OSHA Rule for Extension Cords?

The Occupational Safety and Health Administration (OSHA) has set forth specific guidelines to promote a safer working environment. Here are the key OSHA rules for extension cord usage:

- Extension cords used in projects should always feature three prongs.

- All extension cords must be maintained in pristine working condition.

- At a minimum, quarterly testing for ground continuity of each extension cord is required, with a marking to indicate the inspection date.

- Prior to any use, a visual inspection of each extension cord is obligatory.

- Any cord found in disrepair or failing the continuity test must be tagged, taken out of service, and only reinstated after successful retesting.

- Cords missing the grounding pin are deemed unfit for service.

- Extension cords should never substitute for permanent fixed wiring.

- Running extension cords through walls, ceilings, or floors is strictly prohibited.

- Direct attachment of extension cords to any building surface is not allowed.

- Extension cords should possess hard or extra-hard NEC designations, such as S, ST, SO, STO, SJ, SJO, SJT, SJTO.

- "Flat wire" type extension cords are not permissible.

- All extension cords should feature individually insulated wires with an additional protective outer cover.

Safety and Maintenance Tips

Proper Storage: To prolong the lifespan of your extension cords, always coil them loosely and store them in a dry, cool place. Avoid leaving cords tangled or under heavy objects, as this can lead to internal damage and decrease their efficiency.

Avoid Overloading: Always be mindful of the electrical capacity of your extension cords. Overloading can not only damage the cord but also pose a fire hazard, so ensure the total wattage of the connected devices doesn't exceed the cord's capacity.

Avoid Pinching or Crimping: Ensure that your extension cords aren't pinched in doors, windows, or under heavy furniture. Continual pressure can damage the insulation, leading to exposed wires and increasing the risk of electrical hazards.

Promptly Replace Damaged Cords: Never attempt to repair a damaged extension cord with tape or other temporary fixes. If a cord is damaged, it's safest to replace it entirely to ensure you're not taking unnecessary risks.

Frequently Asked Questions

What is the most heavy-duty extension cord?

The term "heavy-duty" can be subjective and can depend on specific applications. Generally, extension cords that are 10-gauge or thicker and have a high amp capacity (like 15 amps or more) are considered heavy-duty

What gauge is an industrial extension cord?

Industrial extension cords typically range between 8-gauge to 12-gauge, depending on their intended use. The lower the gauge number, the thicker the wire, which means it can carry more current over longer distances.

What is the best heavy-duty outdoor extension cord?

The best outdoor extension cord heavy duty would be one that's designed to resist environmental factors like water, UV rays, and extreme temperatures.

What is the best extension cord for heavy appliances?

For heavy appliances, you'll want an extension cord that has a large gauge (thick wire) and a high amp rating to handle the load. Cords that are 10-gauge or 12-gauge with a 15 amp or higher rating are ideal.

What gauge extension cord is OSHA approved?

OSHA doesn't specifically approve or disapprove extension cords based on their gauge. Instead, OSHA provides guidelines on the safe use of extension cords in the workplace. The right gauge will depend on the intended use and power requirements of the connected equipment.

How long is too long for an extension cord?

It depends on the gauge and power needs. Typically, the longer the cord, the more voltage drop occurs, which can reduce efficiency. For high-power tools or appliances, shorter cords (less than 100 feet) are recommended.

How many volts can a standard extension cord handle?

Most household extension cords can handle up to 125 or 250 volts, but always check the cord's specifications to be sure.

Which is better, 14-gauge or 16-gauge extension cord?

14-gauge is thicker and can handle more amperage than 16-gauge, making it more suitable for higher-powered appliances and tools.