-

0%

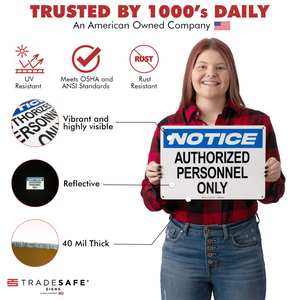

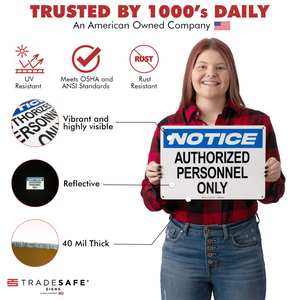

Notice - Authorized Personnel Only Aluminum Sign

Regular price $24.95Regular price$25.000%Sale price $24.95 -

0%

All Visitors Must Register at Office Aluminum Sign

Regular price $24.95Regular price$25.000%Sale price $24.95 -

0%

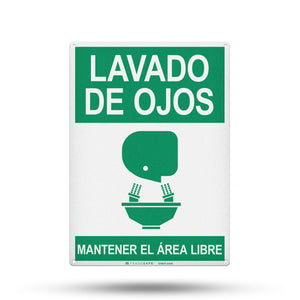

Lavado De Ojos Mantener El Área Libre (Eye Wash Keep Area Clear) Aluminum Sign

Regular price $24.95Regular price$25.000%Sale price $24.95 -

0%

Eye Wash Keep Area Clear Aluminum Sign

Regular price $24.95Regular price$25.000%Sale price $24.95 -

0%

Estación De Primeros Auxilios (First Aid Station) Aluminum Sign

Regular price $24.95Regular price$25.000%Sale price $24.95 -

-20%

Hearing Protection and Safety Glasses Aluminum Sign

Regular price $19.95Regular price$25.00-20%Sale price $19.95 -

-20%

Zapatos de Seguridad Requeridos (Safety Shoes Required) Aluminum Sign

Regular price $19.95Regular price$25.00-20%Sale price $19.95 -

-20%

Safety Shoes Required Aluminum Sign

Regular price $19.95Regular price$25.00-20%Sale price $19.95 -

-20%

Lentes de Seguridad Requeridos (Safety Glasses Required) Aluminum Sign

Regular price $19.95Regular price$25.00-20%Sale price $19.95 -

-20%

Safety Glasses Required Aluminum Sign

Regular price $19.95Regular price$25.00-20%Sale price $19.95 -

-20%

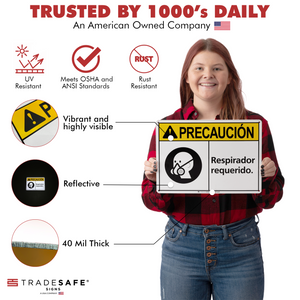

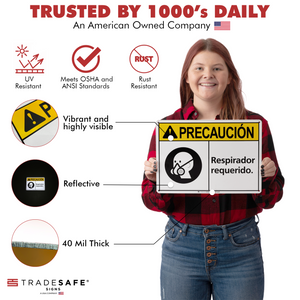

Respirador Requerido (Respirator Required) Aluminum Sign

Regular price $19.95Regular price$25.00-20%Sale price $19.95 -

-20%

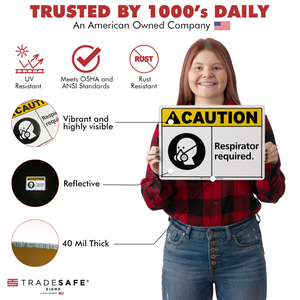

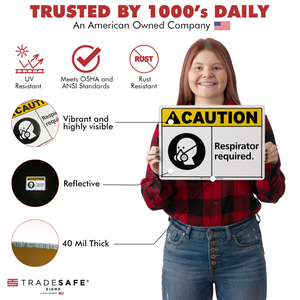

Respirator Required Aluminum Sign

Regular price $19.95Regular price$25.00-20%Sale price $19.95 -

-20%

PPE Requerido (PPE Required) Aluminum Sign

Regular price $19.95Regular price$25.00-20%Sale price $19.95 -

-20%

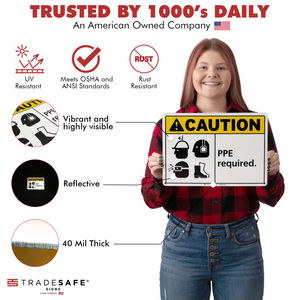

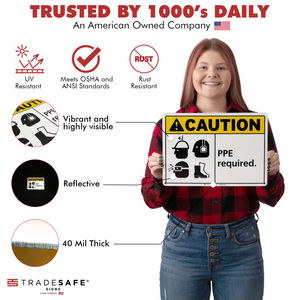

PPE Required Aluminum Sign

Regular price $19.95Regular price$25.00-20%Sale price $19.95 -

-34%

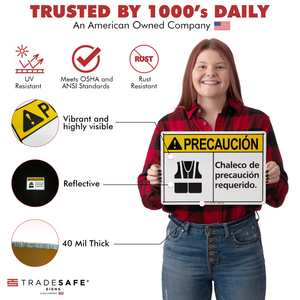

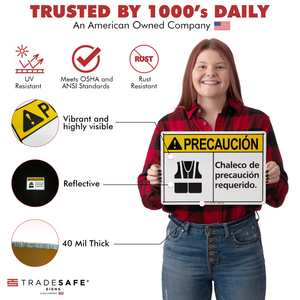

Chaleco de Precaución Requerido (Safety Vest Required) Aluminum Sign

Regular price $19.95Regular price$30.00-34%Sale price $19.95 -

-20%

Protección Auditiva Requerida (Hearing Protection Required) Aluminum Sign

Regular price $19.95Regular price$25.00-20%Sale price $19.95 -

-20%

Hearing Protection Required Aluminum Sign

Regular price $19.95Regular price$25.00-20%Sale price $19.95 -

-20%

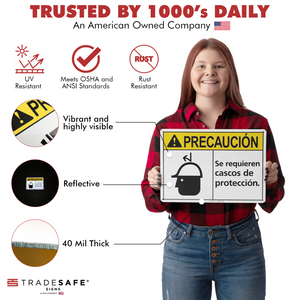

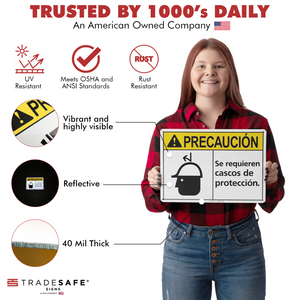

Se Requieren Cascos de Protección (Hard Hats Required) Aluminum Sign

Regular price $19.95Regular price$25.00-20%Sale price $19.95 -

-20%

Hard Hats Required Aluminum Sign

Regular price $19.95Regular price$25.00-20%Sale price $19.95 -

-20%

Protección Ocular Requerida (Eye Protection Required) Aluminum Sign

Regular price $19.95Regular price$25.00-20%Sale price $19.95 -

-38%

Anti-Slip Floor Sign – One Way/Circulación – One Way Sign – Circulación de Una Vía – Bilingual (English/Spanish)

Regular price $36.95Regular price$60.00-38%Sale price $36.95 -

-38%

Anti-Slip Floor Sign – Stop Wait Here Sign

Regular price $36.95Regular price$60.00-38%Sale price $36.95 -

-38%

Anti-Slip Floor Sign – Mantener el Área Libre – Keep Area Clear Sign in Spanish

Regular price $36.95Regular price$60.00-38%Sale price $36.95 -

-38%

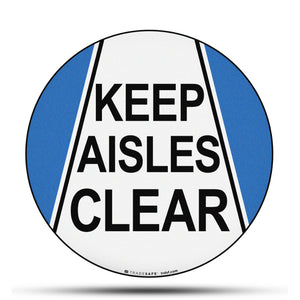

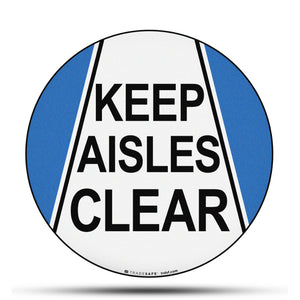

Anti-Slip Floor Sign – Keep Aisles Clear Sign

Regular price $36.95Regular price$60.00-38%Sale price $36.95 -

-38%

Anti-Slip Floor Sign – No Forklifts In This Area Sign

Regular price $36.95Regular price$60.00-38%Sale price $36.95 -

-38%

Anti-Slip Floor Sign – Stop – Employees Only Sign

Regular price $36.95Regular price$60.00-38%Sale price $36.95 -

Sold out

Anti-Slip Floor Sign – Extinguidor – Fire Extinguisher Arrow Sign in Spanish

Regular price $36.95Regular price$60.00-38%Sale price $36.95 -

-38%

Anti-Slip Floor Sign – Fire Extinguisher Arrow Sign

Regular price $36.95Regular price$60.00-38%Sale price $36.95 -

-38%

Red Arrow Sign Floor Decal

Regular price $36.95Regular price$60.00-38%Sale price $36.95 -

-38%

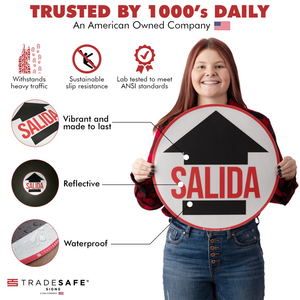

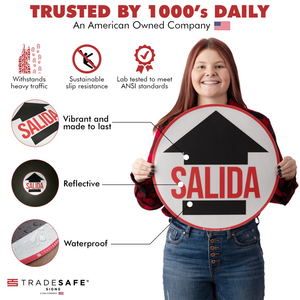

Salida Sign with Up Arrow Floor Sticker

Regular price $36.95Regular price$60.00-38%Sale price $36.95 -

-38%

Exit Sign with Up Arrow Floor Sticker

Regular price $36.95Regular price$60.00-38%Sale price $36.95 -

-38%

Alto Spanish Sign Floor Sticker

Regular price $36.95Regular price$60.00-38%Sale price $36.95 -

-38%

Eye Wash Station Floor Sign

Regular price $36.95Regular price$60.00-38%Sale price $36.95 -

-38%

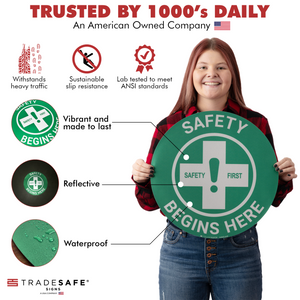

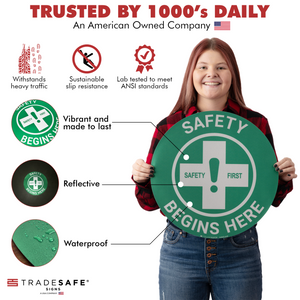

Safety Begins Here Floor Sign

Regular price $36.95Regular price$60.00-38%Sale price $36.95 -

-38%

Anti-Slip Floor Sign – Slippery When Wet Sign

Regular price $36.95Regular price$60.00-38%Sale price $36.95 -

-38%

Área de Uso De Cascos Spanish Floor Sign

Regular price $36.95Regular price$60.00-38%Sale price $36.95 -

-38%

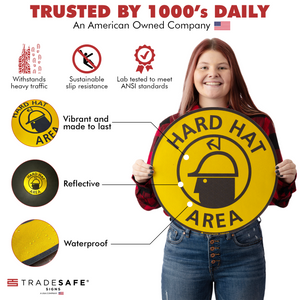

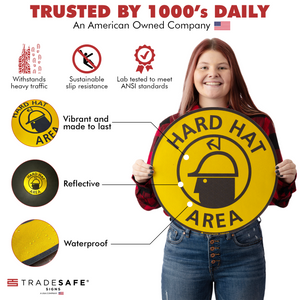

Hard Hat Area Floor Sign

Regular price $36.95Regular price$60.00-38%Sale price $36.95 -

-38%

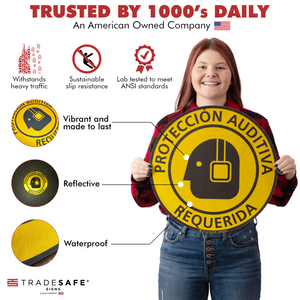

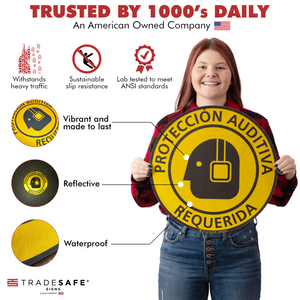

Protección Auditiva Requerida Spanish Floor Sign

Regular price $36.95Regular price$60.00-38%Sale price $36.95 -

-38%

Hearing Protection Required Floor Sign

Regular price $36.95Regular price$60.00-38%Sale price $36.95 -

-38%

Trash Can Sign Floor Sign

Regular price $36.95Regular price$60.00-38%Sale price $36.95 -

-38%

Lentes De Seguridad Requeridos Spanish Floor Sign

Regular price $36.95Regular price$60.00-38%Sale price $36.95 -

-38%

Zapatos De Seguridad Requeridos Spanish Floor Sign

Regular price $36.95Regular price$60.00-38%Sale price $36.95 -

-38%

Watch Your Step Floor Sign

Regular price $36.95Regular price$60.00-38%Sale price $36.95 -

-38%

Pedestrian Traffic Only Floor Sign

Regular price $36.95Regular price$60.00-38%Sale price $36.95 -

-39%

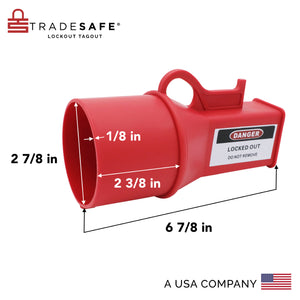

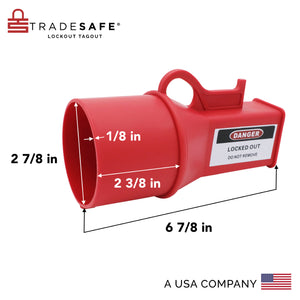

Pin and Sleeve Socket Lockout Device – 2-7/8” Diameter

Regular price $29.95Regular price$49.00-39%Sale price $29.95 -

-49%

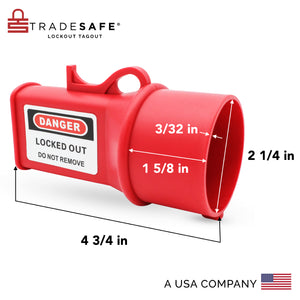

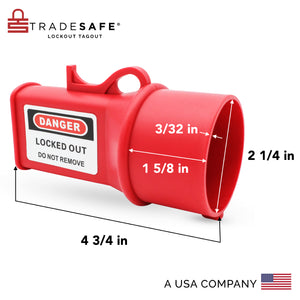

Pin and Sleeve Socket Lockout Device – 2-1/4” Diameter

Regular price $24.95Regular price$49.00-49%Sale price $24.95 -

-49%

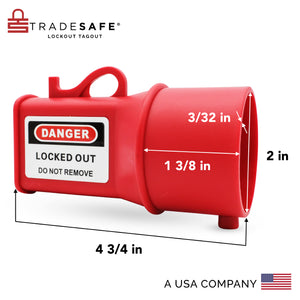

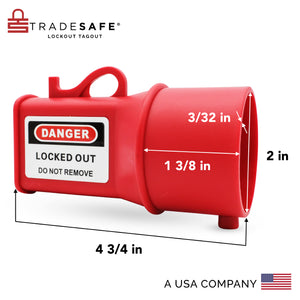

Pin and Sleeve Socket Lockout Device – 2” Diameter

Regular price $19.95Regular price$39.00-49%Sale price $19.95 -

0%

First Aid Station Aluminum Sign

Regular price $24.95Regular price$25.000%Sale price $24.95

It is only imperative that industrial workplaces prioritize occupational health and safety. Because factories, industrial plants, and other high-risk workplaces have a lot of occupational hazards, companies must ensure their employees have the tools and training to maintain a safe working environment.

The Occupational Safety and Health Administration (OSHA) is part of the United States Department of Labor that guarantees employees' safety and health by establishing and enforcing standards as well as providing training, outreach, information, and support.

At TRADESAFE, every product is made of premium quality materials, precision-engineered to be easy to use, and constructed to comply with OSHA standards. Our collection includes absorbents, eyewash stations, lockout tagout devices and supplies, and signs. Keep your trade safe with TRADESAFE, a trusted industrial safety brand.