Industrial hygiene is crucial for maintaining a safe and healthy work environment. It focuses on minimizing risks and enhancing the health of workers by managing potential hazards in the workplace. A key part of this strategy involves using industrial hygiene tools and equipment, such as safety wash stations, effectively. In this article, we'll explore what industrial hygiene is, why it's important, and the various tools that play a vital role in ensuring worker safety.

What is Industrial Hygiene?

Industrial hygiene is the complex art and science of anticipating, recognizing, evaluating, and controlling workplace conditions that may cause worker’s sickness or injury. Certified industrial hygienists conduct workplace analysis and assessment, environmental monitoring, and analytical methods to detect the extent of worker exposure to potential hazards. This process employs engineering, work practice controls, and other methods to control and manage potential health hazards.

Importance of Industrial Hygiene

Industrial hygiene is essential for several reasons, especially when it comes to maintaining a safe and healthy workplace. Reports show that the leading causes of occupational injuries responsible for worker Day Away From Work (DAFW) include exposure to harmful substances or environment (28%), overexertion (23%), falls, slips, and trips (20%), and contact with objects/equipment (20%). In addition, the National Safety Council (NSC) reports a 5% increase in preventable work deaths and fatal injuries in 2022, based on data gathered by the Bureau of Labor Statistics (BLS).

Considering this, the implementation of industrial hygiene plans can be key in preventing injury and accidents and ensuring worker safety. For a better understanding, here are some key aspects that highlight the significance of industrial hygiene:

- Preventing Workplace Illnesses and Injuries: By identifying and managing exposure to harmful chemicals, noise, and other hazardous agents, industrial hygiene helps prevent various health issues. These can range from respiratory problems and skin diseases to serious conditions like cancer or hearing loss.

- Enhancing Worker Productivity: A healthy workforce is a more productive workforce. When workers are healthy and their workplace environment is safe, they are able to perform at their best. This is directly beneficial to the operations and efficiency of any business.

- Improving Worker Morale and Retention: Workers are more likely to stay with a company that actively promotes their health and safety. By investing in industrial hygiene, businesses show their employees that they care about their well-being, which can boost morale and reduce turnover.

- Cost Savings: Effective industrial hygiene practices can lead to significant cost savings by reducing the number of work-related illnesses and injuries. This can lower medical costs, reduce absenteeism, and decrease workers’ compensation claims.

- Building a Positive Reputation: Companies known for their commitment to safety and health are viewed more favorably by consumers, potential employees, and partners. This reputation can be a competitive advantage in attracting top talent and maintaining customer loyalty.

- Compliance with Health and Safety Regulations: Adhering to occupational health and safety regulations is not just about legal compliance; it's about creating a work culture that values safety and health. Industrial hygiene practices ensure that businesses meet regulatory standards, helping avoid potential fines and legal issues.

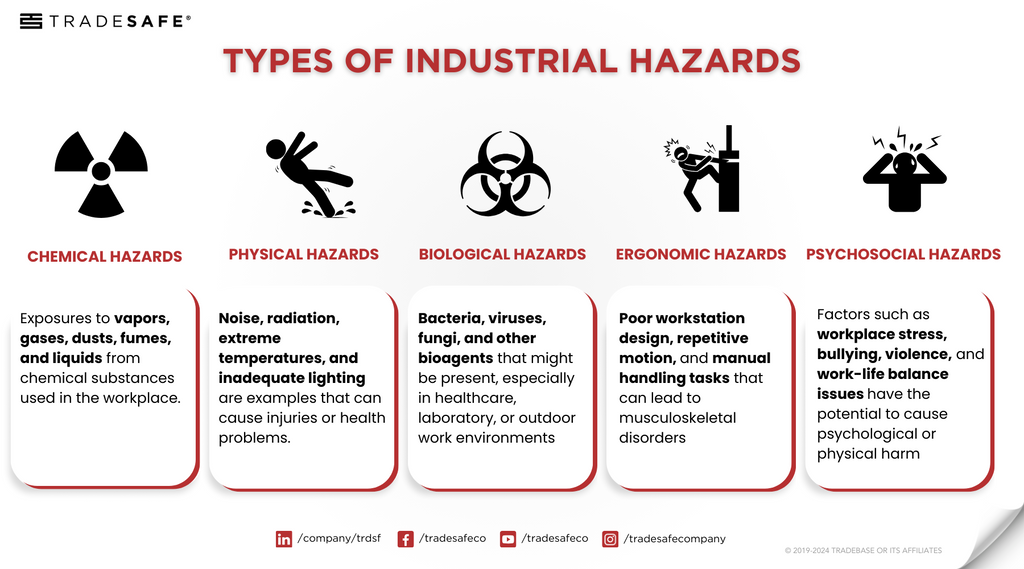

Types of Industrial Hygiene Hazards & Safety Standards

Industrial hygiene encompasses various types, each focusing on different aspects of workplace safety. Understanding these types helps businesses comply with specific safety standards and regulations designed to protect workers. Here’s an overview of the major types of industrial hygiene hazards and the relevant standards and regulations related to them.

Chemical Hazards

Chemical hazards are prevalent in many industrial environments, where workers may be exposed to harmful chemicals in various forms such as liquids, gases, dusts, fumes, and vapors. The control and management of these hazards are critical to ensure worker safety and health.

Key Standards and Regulations:

- OSHA Hazard Communication Standard (HCS): This standard is key in managing chemical risks in the workplace effectively and systematically. It mandates that all employers with hazardous chemicals in their workplaces must have labels and safety data sheets for their exposed workers and train them to handle the chemicals appropriately.

- ACGIH Threshold Limit Values (TLVs): These are guidelines (not enforceable by OSHA) provided by the American Conference of Governmental Industrial Hygienists. They serve as industry benchmarks for exposure limits to chemical substances and physical agents in the workplace. TLVs are updated annually based on the latest scientific research findings.

- EPA Regulations: The Environmental Protection Agency also plays a role, particularly with the Toxic Substances Control Act (TSCA), which governs the introduction and use of new or existing chemicals.

Physical Hazards

Physical hazards in the workplace can include extreme temperatures, noise, radiation, and vibration, each posing significant risks to worker health if not properly managed.

Key Standards and Regulations:

- OSHA Occupational Noise Exposure Standard: This standard specifies exposure limits to noise and requires employers to implement a hearing conservation program if workers are exposed to a time-weighted average sound level of 85 decibels (A scale) or higher during an 8-hour work shift. The program must include periodic hearing tests, provision of hearing protectors, training, and administrative controls.

- OSHA Heat Stress Guidelines: While there are no specific OSHA standards for heat stress, the General Duty Clause requires employers to protect workers from serious hazards, including heat-related hazards. OSHA provides guidelines to help employers and workers understand how to protect against heat stress when working in hot environments.

- Radiation Safety Standards: These are covered under both OSHA standards and the Nuclear Regulatory Commission (NRC). OSHA sets limits on exposure to ionizing radiation and non-ionizing radiation with standards specific to certain types of radiation such as radiofrequency and microwave radiation, visible light, ultraviolet radiation, and laser operations.

Biological Hazards

Biological hazards involve working with or exposure to harmful biological agents, including bacteria, viruses, fungi, and other microorganisms that can affect health. These hazards are particularly relevant in healthcare, laboratory environments, and any workplaces dealing with organic matter or animals.

Key Standards and Regulations:

- OSHA Bloodborne Pathogens Standard (29 CFR 1910.1030): This critical standard requires employers to protect workers who are at risk of exposure to blood or other potentially infectious materials. It mandates a comprehensive program that includes exposure control plans, training, and the provision of personal protective equipment (PPE).

- CDC Guidelines: The Centers for Disease Control and Prevention (CDC) provide extensive guidance on handling infectious diseases in the workplace. These guidelines are essential resources for understanding how to prevent and respond to biological hazards effectively.

Ergonomic Hazards

Ergonomic hazards arise from physical factors in the workplace that can result in musculoskeletal disorders (MSDs), such as repetitive strain injuries, carpal tunnel syndrome, or back injuries. These hazards are common in jobs involving repetitive tasks, heavy lifting, or prolonged sitting or standing.

Key Standards and Regulations:

- General Duty Clause of the OSHA Act: Specific ergonomic standards have not been established by OSHA, but the General Duty Clause (Section 5(a)(1)) requires employers to provide a workplace free from recognized hazards that are causing or are likely to cause death or serious physical harm. This clause is often applied to ergonomic hazards.

- OSHA Ergonomic Guidelines: While not enforceable standards, OSHA has developed industry-specific ergonomic guidelines to help employers reduce ergonomic risks. These guidelines offer practical solutions and strategies tailored to various sectors, including healthcare, construction, and grocery retailing.

- State-Specific Ergonomic Standards: Some states, such as California, have developed their own ergonomic standards that are enforceable within those states. These regulations often provide specific requirements for addressing ergonomic risks in certain industries or occupations.

Psychosocial Hazards

Psychosocial hazards are aspects of work and work environments that have the potential to cause psychological or physical harm. These hazards include factors such as workplace stress, bullying, violence, and work-life balance issues. The impacts of psychosocial hazards can be profound, affecting mental health, contributing to stress-related disorders, and even causing physical health issues.

Key Standards and Regulations:

- OSHA Guidelines for Preventing Workplace Violence: OSHA provides guidelines for industries particularly prone to workplace violence, such as healthcare and social service settings. These guidelines recommend implementing comprehensive violence prevention programs, which include risk assessment, strategies to mitigate risks, training for staff, and incident response plans.

- NIOSH Recommendations: The National Institute for Occupational Safety and Health (NIOSH) offers extensive research and recommendations on workplace stress. While these are not enforceable rules, they provide valuable guidance on designing work environments that reduce stress and improve worker well-being.

- State and Local Legislation: Some states have begun to develop legislation related to workplace bullying and psychological safety. For example, certain states require training for public employees on preventing workplace violence.

Key Elements of An Industrial Hygiene Program

An effective industrial hygiene strategy is essential for preventing workplace illnesses and injuries. It involves a systematic approach to identifying, evaluating, and controlling environmental factors or stresses arising in or from the workplace. Here are the key elements that make up a robust industrial hygiene program.

Worksite Hazard Analysis: Identifying Industrial Hygiene Hazards

The first step in a worksite hazard analysis is to identify potential sources of hazards. This involves a thorough examination of the workplace to spot any physical, chemical, biological, or ergonomic risks that might pose a threat to worker health and safety. The identification process uses tools such as inspections, employee feedback, and review of health records to ensure a comprehensive hazard mapping.

Exposure Evaluation and Risk Assessment: Gauging Risk Potential

Once hazards are identified, the next step is to evaluate the level of exposure and assess the associated risks. This process helps in understanding which hazards are most harmful and require immediate attention.

Monitor hazard exposure levels using instruments and methods like air sampling and direct reading instruments to measure and gauge the magnitude workers are exposed to. Quantify the assessment by analyzing the exposure data gathered against acceptable standards and guidelines. Then, determine control and management priorities based on hazard severity and likelihood of exposure to ensure that the most significant risks are addressed first.

Hazard Control, Management, and Mitigation

The final element focuses on implementing strategies to control, manage, and mitigate the identified hazards. This involves:

- Engineering Controls: Making changes to the work process or the equipment to reduce exposure, such as improving ventilation or using noise-dampening technologies.

- Administrative Controls: Changing the way people work, such as scheduling work at less risky times, rotating job assignments to reduce exposure to hazards, and providing training to increase safety awareness.

- Personal Protective Equipment (PPE): When exposure cannot be adequately controlled by other means, providing workers with appropriate protective gear like gloves, masks, and protective clothing is necessary.

Industrial Hygiene Safety Tools and Equipment

Industrial hygiene safety tools and equipment play a crucial role in protecting workers from potential hazards in the workplace. These provide industrial hygienists with the necessary information to conduct appropriate efforts to enhance workplace conditions and ensure worker health and safety when dealing with industrial hygiene hazards. Here’s an overview of key tools and equipment industries can use for industrial hygiene strategies:

AQ Profiler

An AQ Profiler, or Air Quality Profiler, is a sophisticated tool used to assess the quality of air within a work environment. It measures various pollutants and environmental parameters, providing data that is crucial for evaluating air safety. It operates by sampling the air and analyzing it for contaminants such as volatile organic compounds (VOCs), particulates, carbon monoxide, and other harmful substances. The results help in assessing whether the air quality is within safe limits and determine the necessity for ventilation improvements or other air management strategies.

This tool is particularly relevant for controlling airborne hazards in industries such as manufacturing, where industrial processes can release harmful particulates or gases; construction, where dust and chemical use are prevalent; and any indoor environment where air quality is a concern, such as office buildings and warehouses.

Wet Bulb Globe Thermometer

The wet bulb globe thermometer (WBGT) is a device used to measure heat stress in direct sunlight, which accounts for temperature, humidity, wind speed, sun angle, and cloud cover (solar radiation). It is essential for assessing environmental conditions that could lead to heat-related illnesses.

The WBGT is used by placing it in the work area to monitor the heat conditions continuously. This tool is particularly relevant in outdoor industries like construction, agriculture, and mining, where workers are exposed to environmental heat. It is also used in industrial settings like foundries and steel mills where high temperatures are a part of the operational environment.

Dosimeters

Dosimeters are devices used to measure an individual’s exposure to hazardous substances over time, particularly to noise and radiation. They are critical for ensuring that exposure levels do not exceed safe limits as defined by regulatory standards. Noise dosimeters are typically worn on the body throughout the workday to record the cumulative noise exposure. Similarly, radiation dosimeters are worn to monitor exposure to ionizing radiation.

Dosimeters are used primarily for physical hazards. Noise dosimeters help manage risks in environments with significant background noise, such as manufacturing plants, airports, or construction sites. Radiation dosimeters are essential in medical imaging facilities, nuclear power plants, and research institutions where ionizing radiation is present.

Radiation Meters

Radiation meters, also known as Geiger counters or radiation detectors, are instruments used to detect and measure levels of radiation. They are indispensable for identifying and quantifying radiation in the environment or emitted by materials. They are used by holding them near the suspected source of radiation to measure its intensity. This information is crucial for assessing safety levels, determining necessary protective measures, and ensuring compliance with health and safety regulations.

Radiation meters are applicable in any setting where there is a potential for exposure to radioactive materials. This includes healthcare settings (especially those using radiological imaging), nuclear energy sectors, certain manufacturing processes, and scientific research laboratories.

Eye Wash Station

An eye wash station is a vital piece of safety equipment designed to offer immediate first aid to the eyes if they come into contact with harmful substances. It is a necessary fixture in any work environment where there is a risk of exposure to corrosive chemicals, flying particles, or hazardous dust. It is designed to be easy and quick to use in an emergency. When a worker's eyes are exposed to hazardous materials, they can immediately activate the station (often by a pedal or a push lever) and use the steady stream of water to flush out their eyes, avoiding severe or permanent eye damage.

Eye wash stations are crucial in environments where workers handle or are around hazardous chemicals, such as laboratories, chemical plants, manufacturing facilities, and construction sites where chemical spills or splashes can occur. They are specifically important for mitigating risks associated with acids, bases, and other irritants that can cause serious eye injuries or blindness.

Safety Shower Station

A safety shower station is designed to deliver large volumes of water instantly to wash off hazardous substances that may come into contact with the skin or clothing. It is an essential emergency fixture in workplaces dealing with large volumes of or particularly dangerous chemicals.

Safety shower stations are critical in settings where there is a potential for spillage or splashing of corrosive or highly toxic chemicals. This includes industries like petrochemicals, pharmaceuticals, and manufacturing where bulk chemicals are processed and handled. They help manage risks from exposures that could cause immediate skin burns or other serious dermal conditions. Aside from this, safety showers can also be used for decontamination against viral or infectious biological hazards.

Hand Wash Station

A hand wash station is a facility designed to allow workers to clean their hands thoroughly, preventing the spread of contaminants and reducing the risk of occupational diseases. It is particularly vital in environments where workers handle hazardous substances or where cleanliness is crucial to safety and health. These stations are essential in managing chemical and biological hazards. They are commonly found in industries such as healthcare, food processing, chemical manufacturing, and any other sectors where cleanliness is a critical component of occupational safety.

Personal Protective Equipment

Personal Protective Equipment (PPE) refers to any gear or clothing designed to protect workers from specific hazards in their work environment. PPE is used to provide a barrier between the worker and the hazards they face in the workplace. The type of PPE required depends on the risk assessment of the work tasks and environment. For instance, gloves may be used to protect against chemical burns, while respirators are necessary to prevent inhalation of harmful vapors or dust.

PPE is versatile and applies to a wide range of hazards, including chemical, physical, biological, and ergonomic risks. Each piece of equipment is designed to address specific dangers, such as shielding eyes from flying debris with goggles, protecting the lungs from airborne contaminants using respirators, or guarding the skin against chemical spills with protective clothing.

FAQs

What are the types of hazards defined by industrial hygiene?

Industrial hygiene defines several types of hazards including chemical (e.g., toxins, irritants), physical (e.g., noise, radiation), biological (e.g., bacteria, viruses), ergonomic (e.g., repetitive strain, improper workstation setup), and psychosocial (e.g., stress, workplace violence) hazards.

What are the 4 stages of industrial hygiene approach?

The industrial hygiene approach consists of four distinct stages designed to protect worker health and safety (1) anticipation, involves predicting potential hazards before they occur, (2) recognition involves identifying existing hazards within the workplace, (3) evaluation stage assesses the severity and potential impact of these hazards, and (4) the control stage involves implementing measures to eliminate or reduce these hazard.

What is the difference between a safety officer and an industrial hygienist?

A safety officer focuses on enforcing safety regulations and ensuring compliance with safety standards across all aspects of the workplace. An industrial hygienist specifically focuses on identifying, evaluating, and controlling environmental and occupational health risks to prevent disease and injury in the workplace.

What is the difference between industrial hygiene and occupational hygiene?

Industrial hygiene and occupational hygiene are terms often used interchangeably. However, "industrial hygiene" traditionally focuses more on manufacturing and industrial sectors, whereas "occupational hygiene" broadly covers all aspects of worker health and safety across various industries, including office environments.

What is good industrial hygiene practice?

Good industrial hygiene practice involves systematically identifying, evaluating, and controlling potential workplace hazards to protect workers' health and safety. It includes regular assessments, use of appropriate safety tools and equipment, employee training, and adherence to regulatory standards. Good practice also involves proactive measures to anticipate and mitigate risks before they lead to health issues.