-

-30%

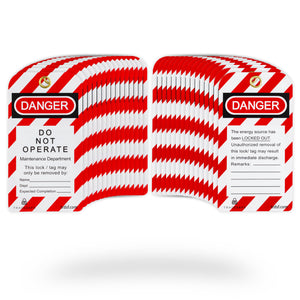

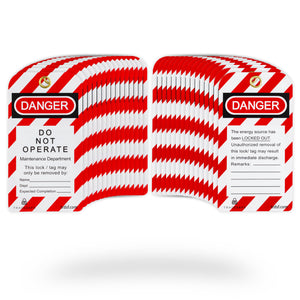

Lockout Tagout Danger Tags – Pack of 10

Regular price $20.95Regular price$30.00-30%Sale price $20.95 -

-38%

Lockout Tagout Danger Tags – Pack of 30

Regular price $36.95Regular price$60.00-38%Sale price $36.95 -

-45%

Lockout Tagout Danger Tags – Pack of 60

Regular price $65.95Regular price$120.00-45%Sale price $65.95 -

-38%

Spanish Lockout Tagout Danger Tags – Pack of 30

Regular price $36.95Regular price$60.00-38%Sale price $36.95 -

-38%

Bilingual Lockout Tagout Danger Tags – Pack of 30

Regular price $36.95Regular price$60.00-38%Sale price $36.95 -

-40%

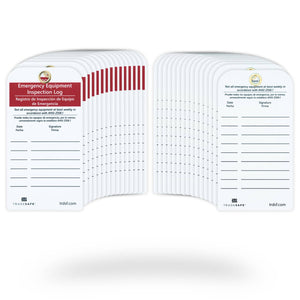

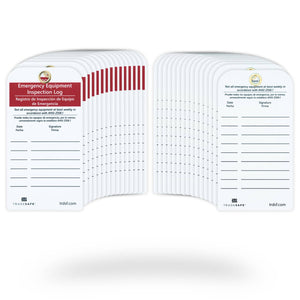

Bilingual Emergency Equipment Inspection Log- Inspección de Equipo de Emergencia - Pack of 30

Regular price $35.95Regular price$60.00-40%Sale price $35.95 -

-50%

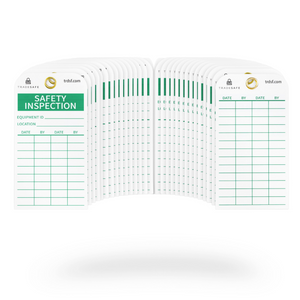

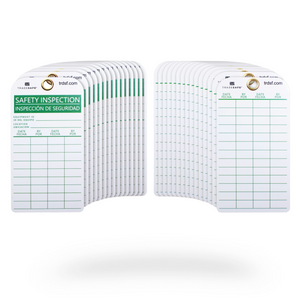

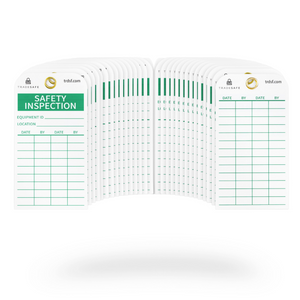

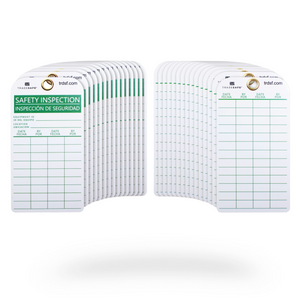

Safety Inspection Tags – Pack of 30

Regular price $29.95Regular price$60.00-50%Sale price $29.95 -

-50%

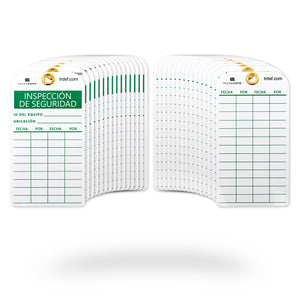

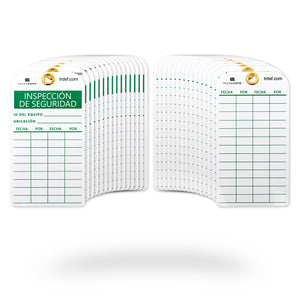

Spanish Safety Inspection Tags – Pack of 30

Regular price $29.95Regular price$60.00-50%Sale price $29.95 -

-50%

Bilingual Safety Inspection Tags – Pack of 30

Regular price $29.95Regular price$60.00-50%Sale price $29.95 -

-40%

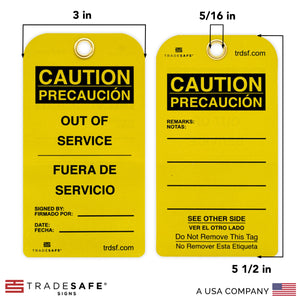

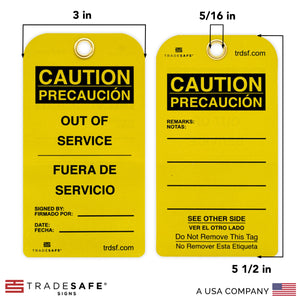

Caution Out of Service Tags - Pack of 30

Regular price $35.95Regular price$60.00-40%Sale price $35.95 -

-40%

Spanish Caution Out of Service Tags - Pack of 30

Regular price $35.95Regular price$60.00-40%Sale price $35.95 -

-40%

Bilingual Caution Out of Service Tags - Pack of 30

Regular price $35.95Regular price$60.00-40%Sale price $35.95 -

-36%

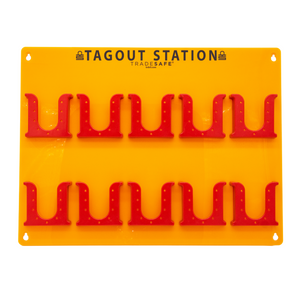

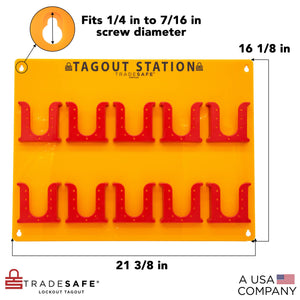

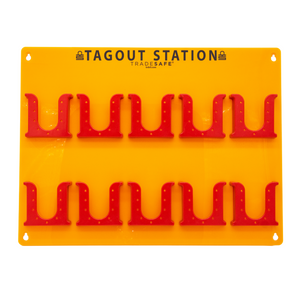

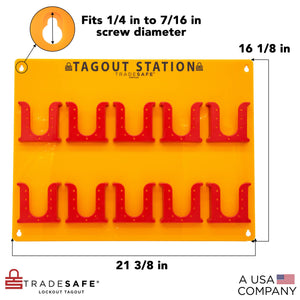

Lockout Tagout Station for LOTO Tags – 150 Tags Included

Regular price $189.95Regular price$299.00-36%Sale price $189.95 -

-65%

Lockout Tagout Station for LOTO Tags - Tags Not Included

Regular price $69.95Regular price$199.00-65%Sale price $69.95 -

-62%

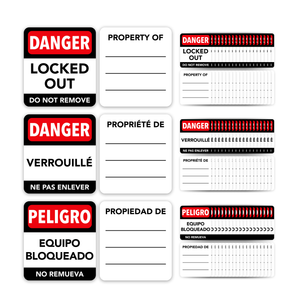

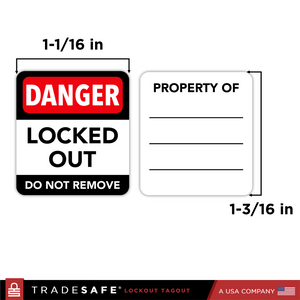

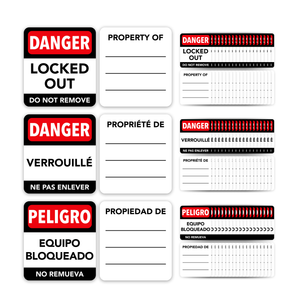

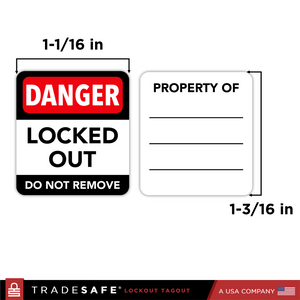

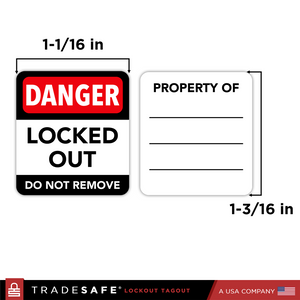

Lockout Tagout Padlock Labels - English, Spanish, French - Pack of 60

Regular price $18.95Regular price$50.00-62%Sale price $18.95 -

-60%

Lockout Tagout Padlock Labels - Pack of 20

Regular price $13.95Regular price$35.00-60%Sale price $13.95 -

-80%

Grease Pencils and Permanent Marker - 3 Pack

Regular price $11.99Regular price$60.00-80%Sale price $11.99 -

-78%

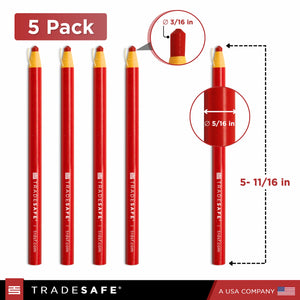

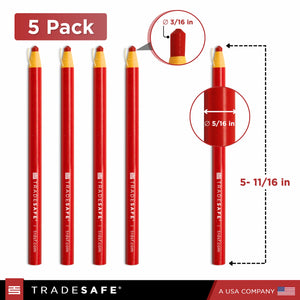

Red Grease Pencils - 5 Pack

Regular price $12.99Regular price$60.00-78%Sale price $12.99 -

-78%

Black Grease Pencils - 5 Pack

Regular price $12.99Regular price$60.00-78%Sale price $12.99

With the help of lockout tagout tags, workers can easily and efficiently alert others to potential hazards. Because these LOTO tags are highly visible and easily noticeable, they’ll be able to convey important warnings and information.

All of TRADESAFE’s lockout tags are made of tear-resistant and durable vinyl or nylon plastic. They are also writeable and designed to be easy to read. Anything written on these lockout tags will remain legible even when they are exposed to water or harsh environmental conditions.

Lockout tagout tags help employees watch out for hazards, keep track of tasks, and find out who among them is accountable for which actions. Tags like these are important in ensuring that lockout tagout programs and their procedures are not just compliant with OSHA 1919.147, but followed to the letter as well.